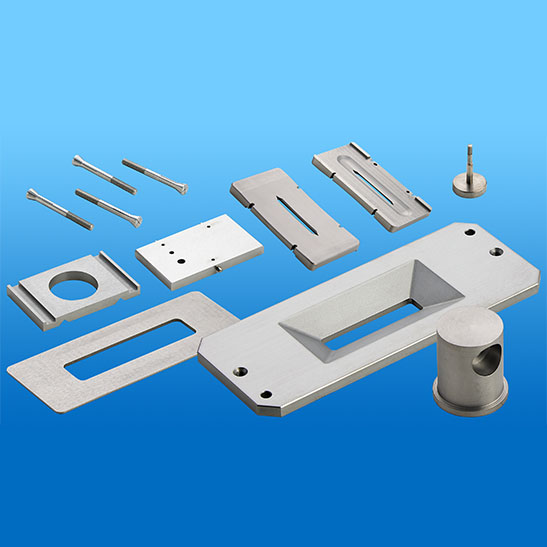

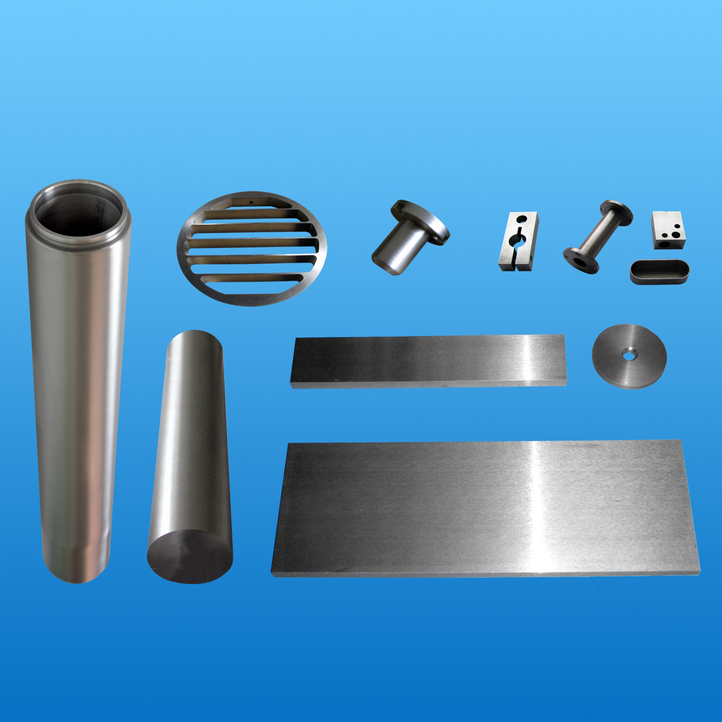

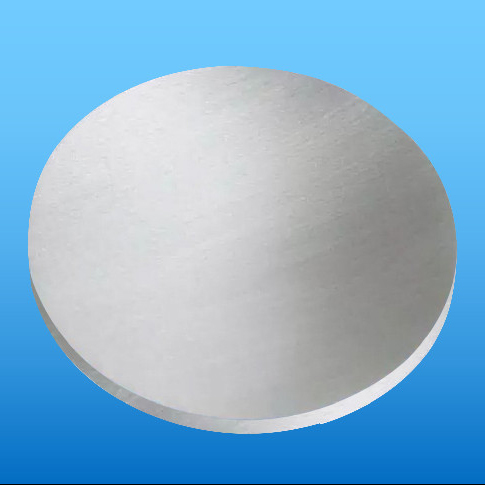

Tungsten-Copper Welded/Back-cast Materials

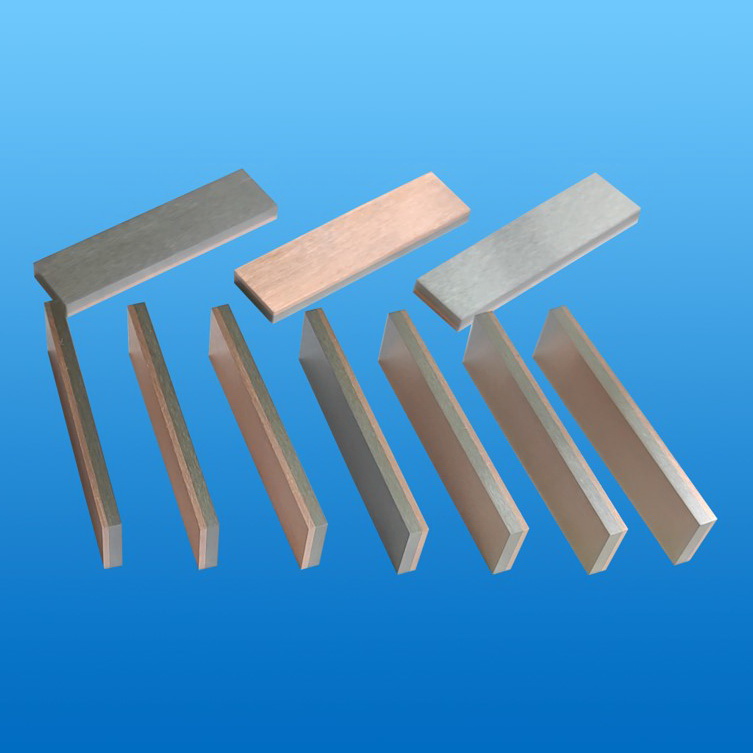

Tungsten-based composites are strong refractory metal materials manufactured by a strictly controlled process involving pressing, sintering, and infiltrating with copper or silver. They are highly resistant to heat, electric arc, wear and deformation at high-temperature welding, flash butt and spot welding. They also have excellent electrical and thermal conductivity. The properties of Tungsten composites are related to the copper/silver-to-Tungsten ratio. If the Tungsten content improves, the electric arc and wear resistance will increase while the thermal and electrical conductivity, on the contrary, reduce.

Due to their unique properties, Tungsten based composites are widely used where the combination of good electrical and/or thermal conductivity and low thermal deformation is necessary, for example:

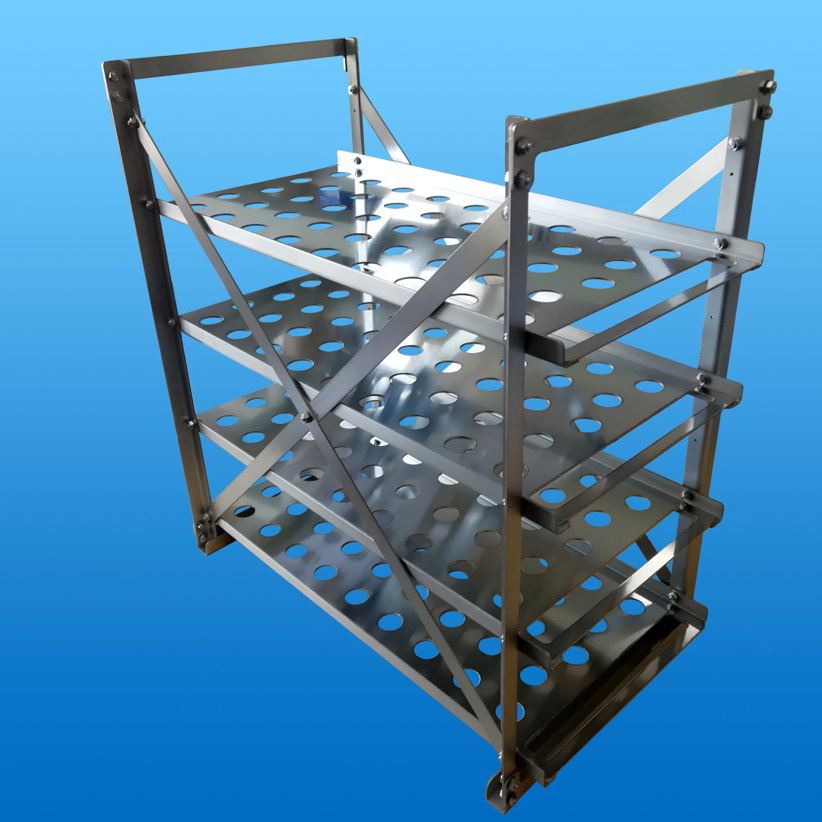

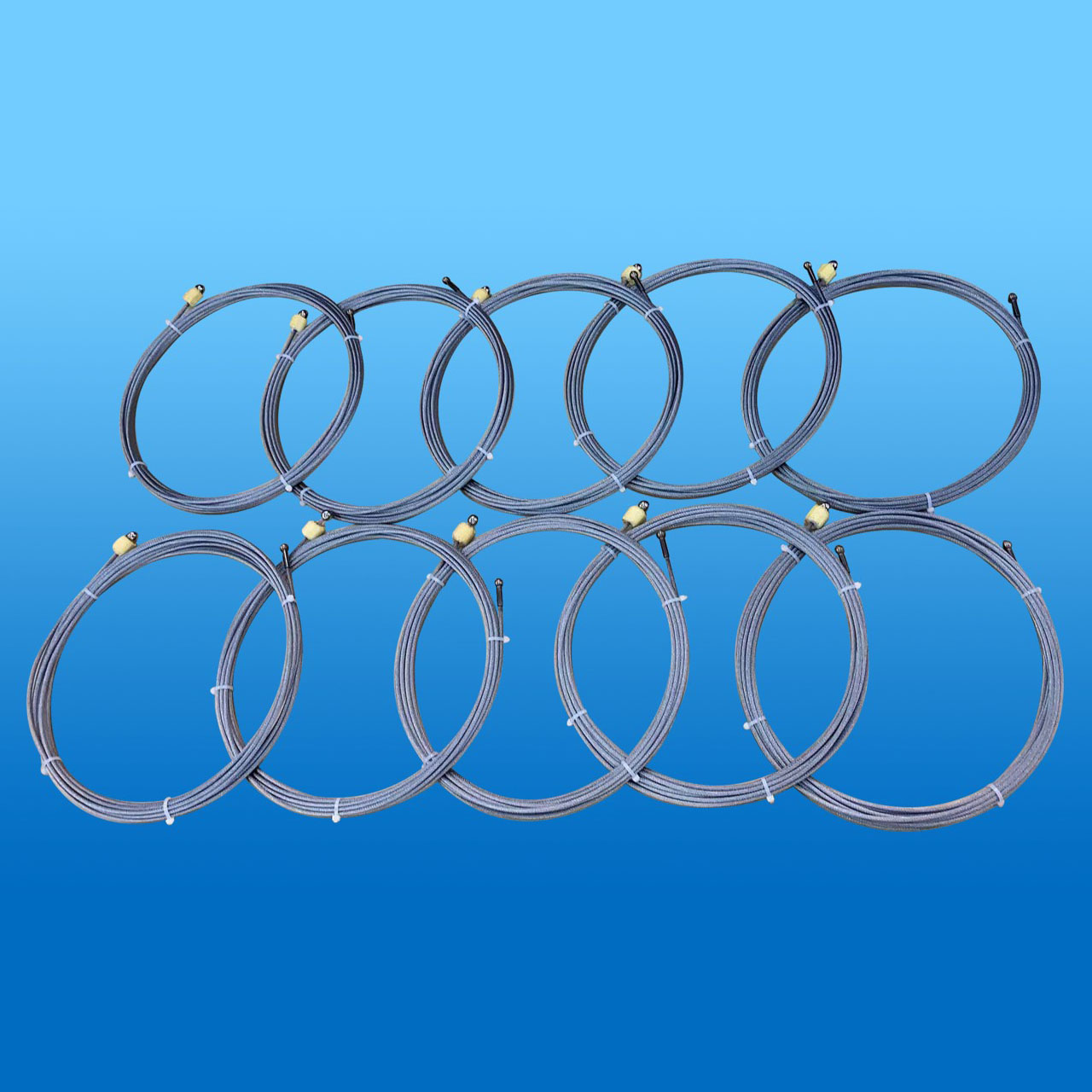

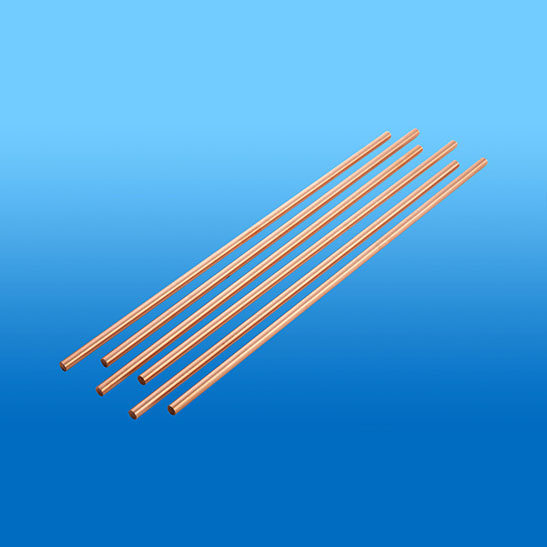

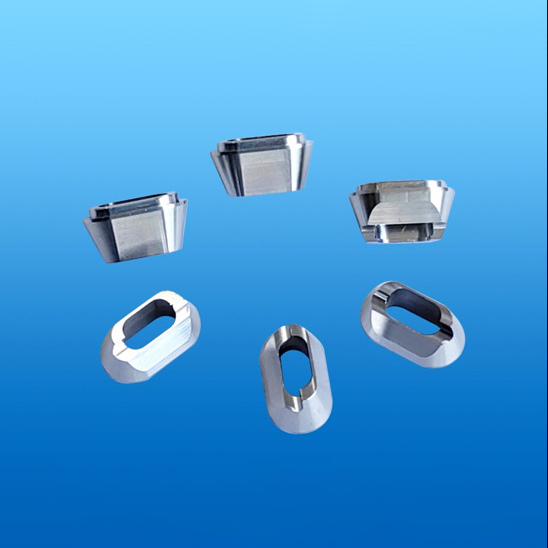

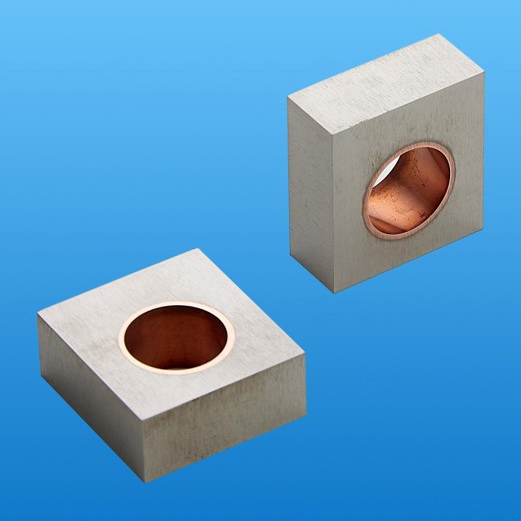

In electric resistance welding as electrical contacts or heat sinks.

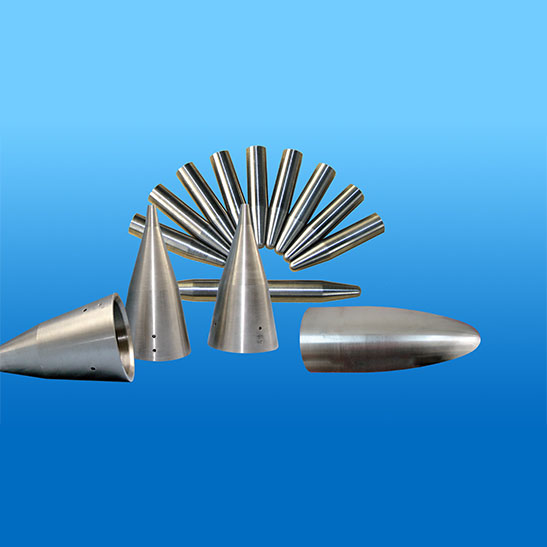

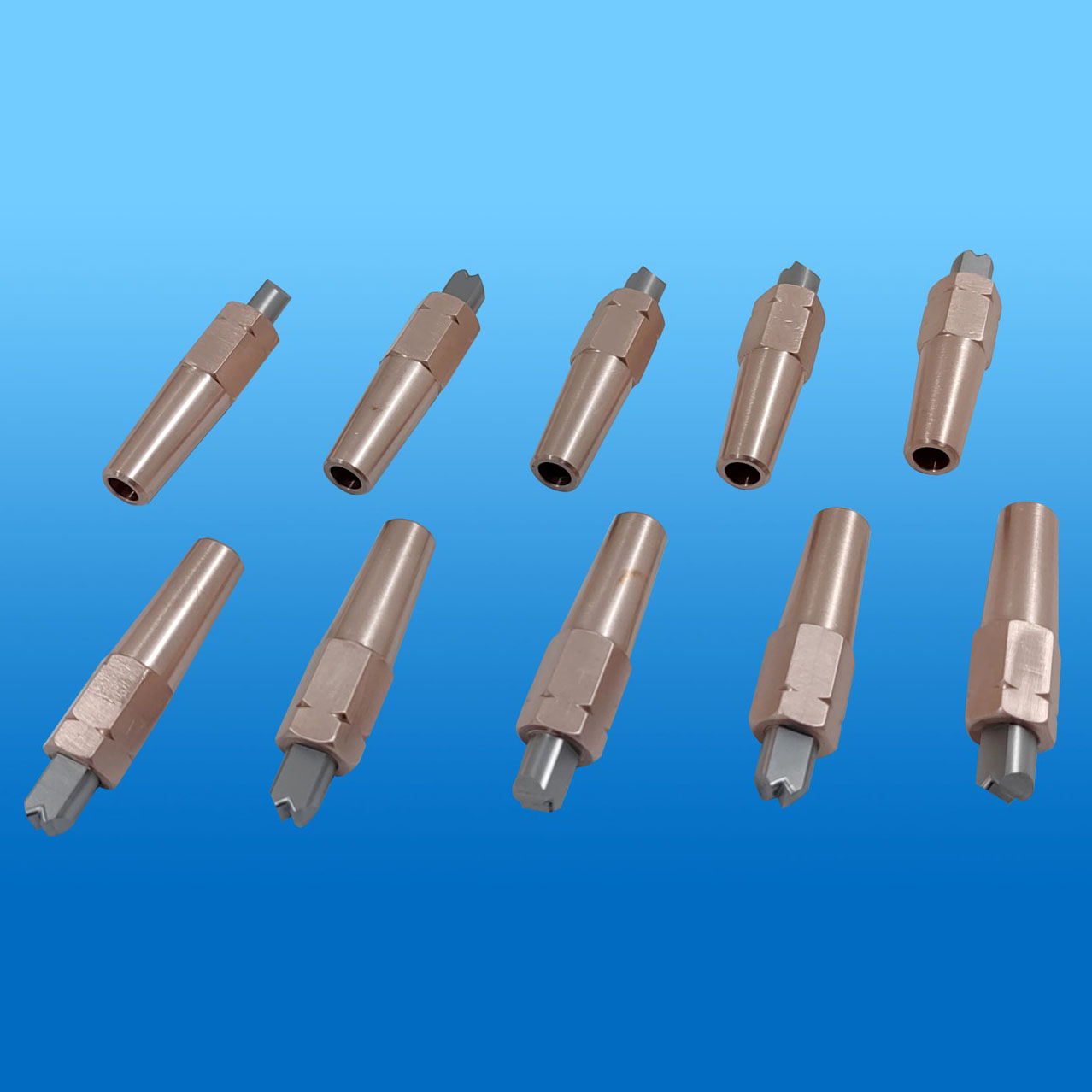

In electrodes for electrical discharge machining (EDM) and electrochemical machining (ECM).

Tungsten-copper composites can be used in the first wall of thermonuclear fusion reactors and bias filter components, high-power resistance welding and arc welding components.

Tungsten-copper composites are investigated as high-performance materials for heat sinks in plasma-facing components. The exhaust of power and particles is currently considered as one of the ultimate challenges for a future demonstration fusion reactor. Predominantly challenging is the design and manufacturing of the plasma-facing components (PFCs) of the divertor. During operation, they have to sustain intense particle, heat and neutron fluxes. Current state-of-the-art designs for water-cooled divertor target plates make use of tungsten as a plasma-facing material, while copper alloys are regarded as most appropriate materials for the heat sink.