Tungsten Resources and Potential Extraction from Mine Waste

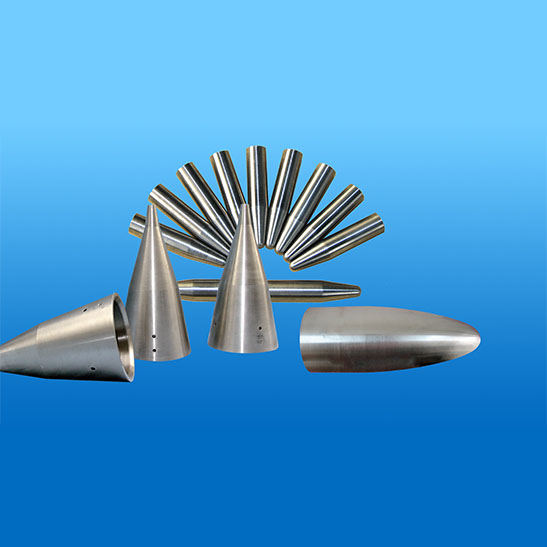

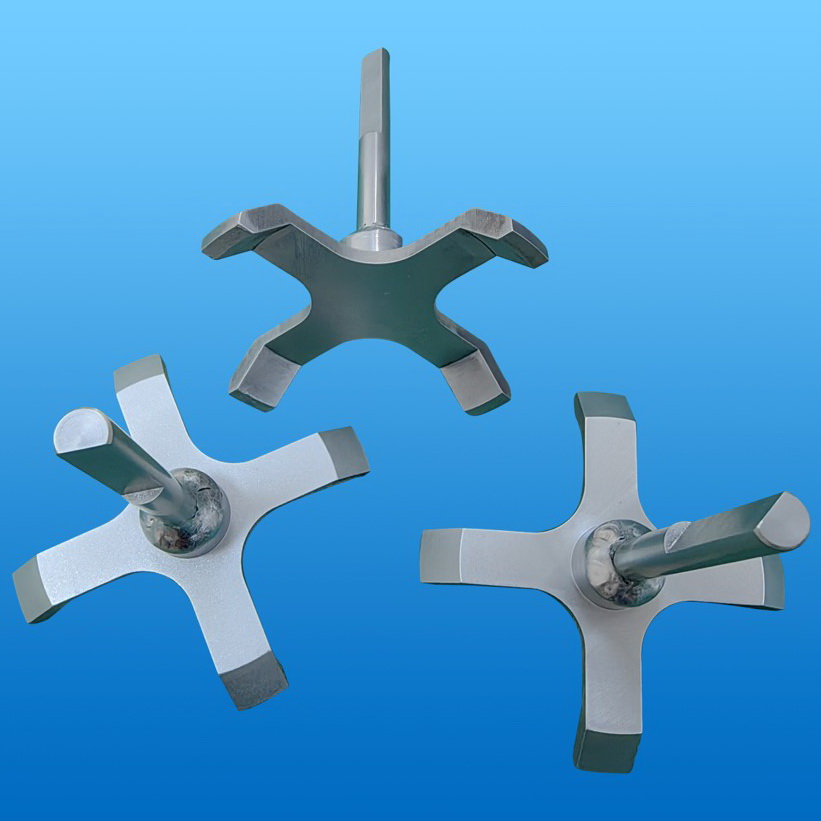

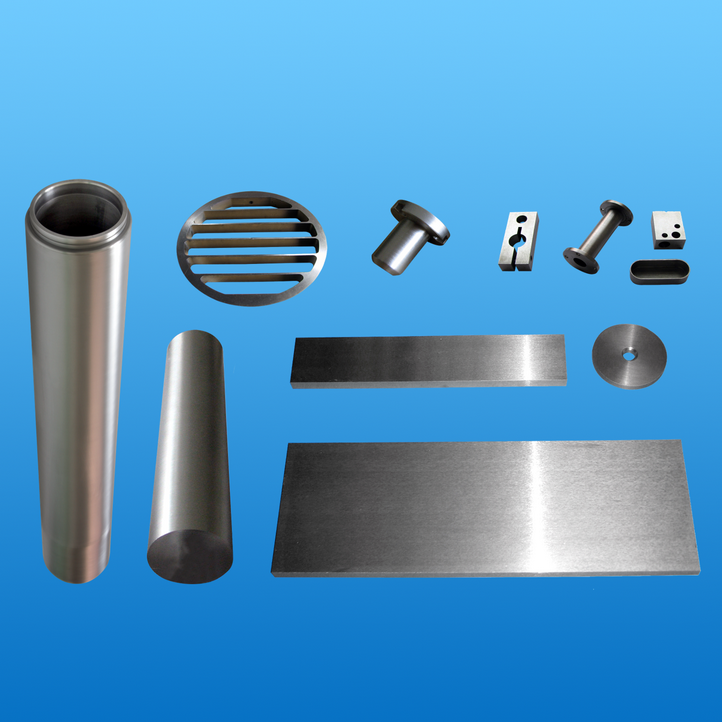

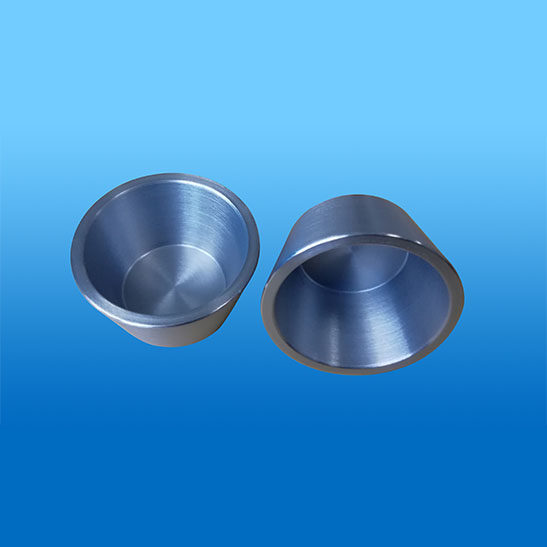

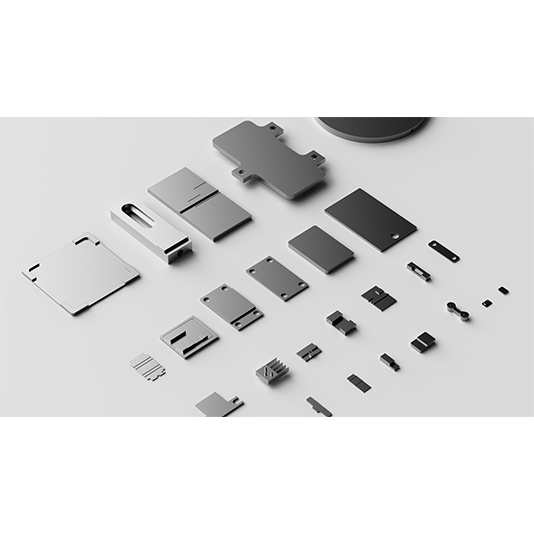

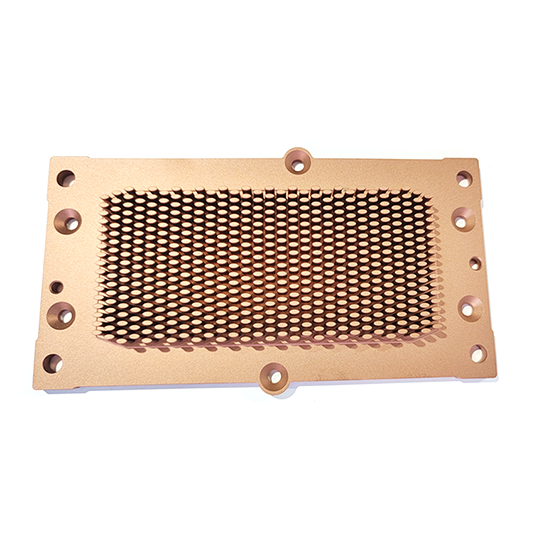

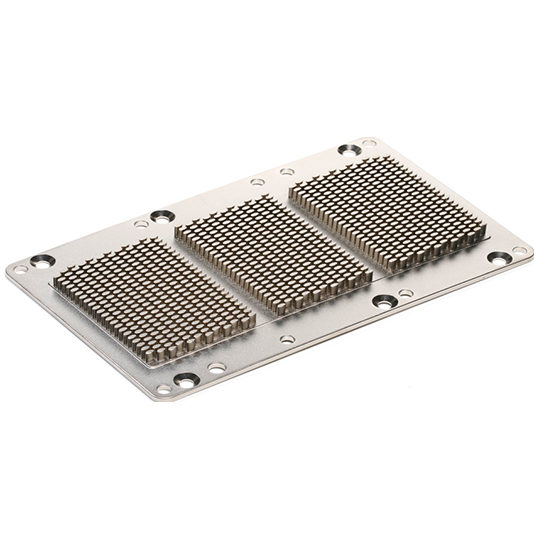

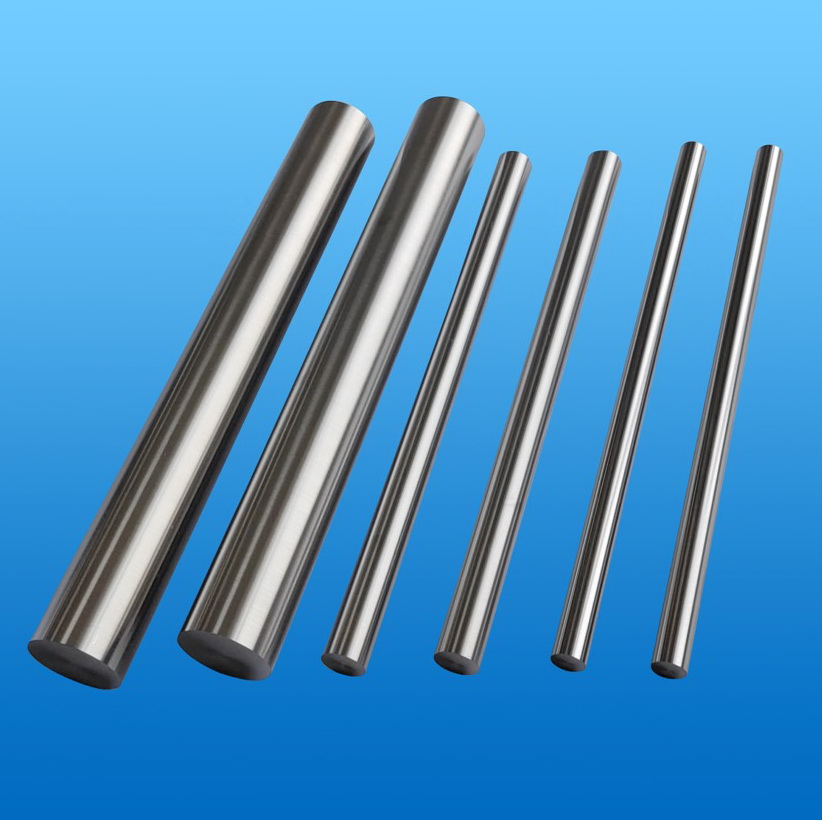

Tungsten is an important raw material and has numerous applications in different industrial sectors, such as energy, materials, information technology, and consumer staples. Specifically, tungsten has been widely used in metalworking, mining and stone-cutting tools, high-temperature technologies, lighting, catalyst and pigment, petroleum, armaments, and aerospace industries. Tungsten carbide—a dense, metal-like substance—is the major end-use material application for tungsten, widely used in automotive and aircraft production, construction, electronics manufacturing, oil and gas drilling, and defense. Recent studies have shown tungsten alloys could be the most promising materials as plasma-facing first walls in future commercial nuclear fusion devices.

The special properties, wide application in different sectors, a lack of potential substitutes, and geographically concentrated production make tungsten a critical element and strategic resource in the global economy. In May 2018, the United States Department of Interior published the Final List of Critical Minerals 2018 (83 FR 23295); tungsten was included in the 35 minerals (or mineral material groups) deemed critical. The European Union also listed tungsten as one of the critical raw materials since 2011. Besides the US and EU, tungsten is considered a critical element in every region except Australia.

China started to dominate the world tungsten market in 1949 and has been the primary tungsten producer for over 70 years. China produced more than 40% of tungsten concentrates between 1949 and 1985 and more than 66% between 1986 and 2008. In 2020, China held 82% of the world’s tungsten mine production and 56% of the world’s tungsten reserves. Meanwhile, China has adopted stricter pollution control and safety regulations on tungsten production and shut down numerous tungsten mining facilities since 2017, which resulted in a reduced supply of tungsten to the world market and high volatility in prices for tungsten commodities. Consequently, to balance the global tungsten demand and supply, markets would need to rely on exploring new primary deposits around the world and utilizing secondary tungsten resources.

Currently, tungsten waste contamination to the environment has also been a concern. For example, the Panasqueira mine, the largest Sn–W deposit in Western Europe, had stored a significant amount of tungsten tailings in tailing dams. These tailings generate low pH (~3) and are enriched in toxic elements acid mine drainage (AMD), leaking into the nearby river. At the Lianhuashan mine, one of the largest tungsten mines in China, it was found that surface water, soil, and plants around the tailing dam were severely contaminated by heavy metals and arsenic. Further study in the same area showed that tungsten tailings have potential health risks to the surrounding residents. Consequently, appropriate treatment for tungsten tailings to prevent potential contamination may be required. Meanwhile, tungsten tailings may contain numerous valuable elements and minerals and could be used as a secondary resource for metal recovery.