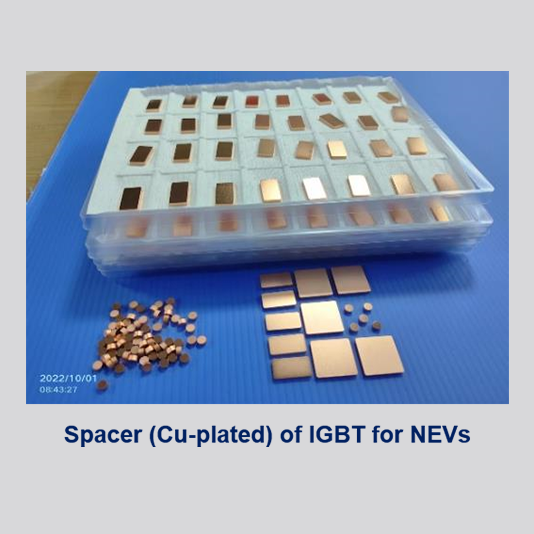

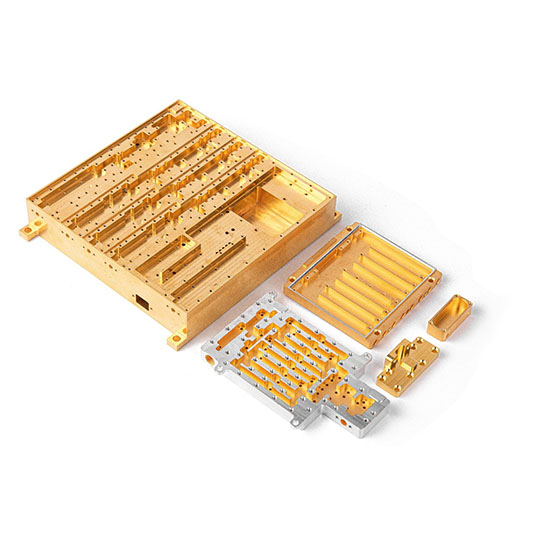

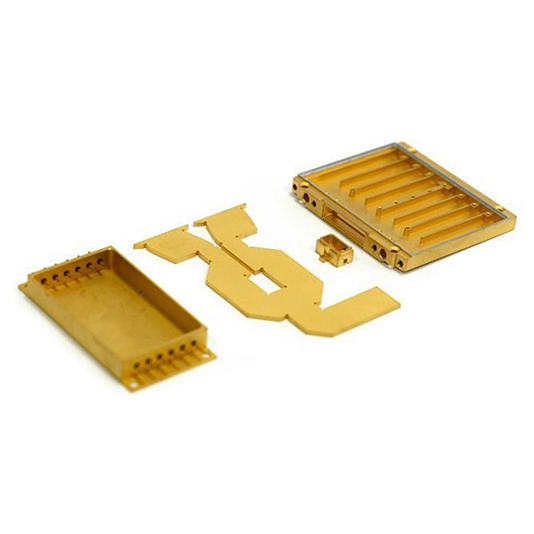

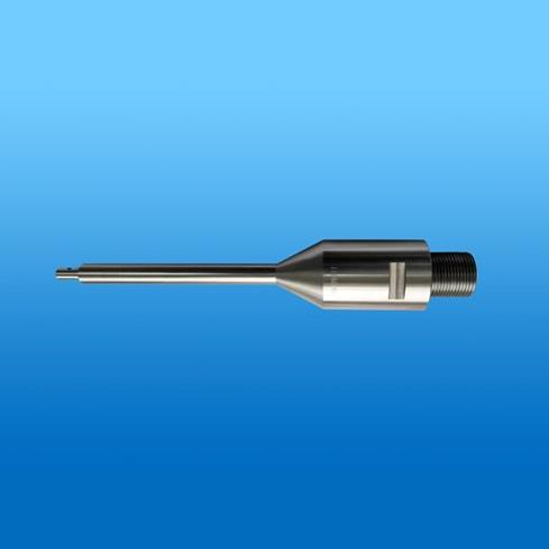

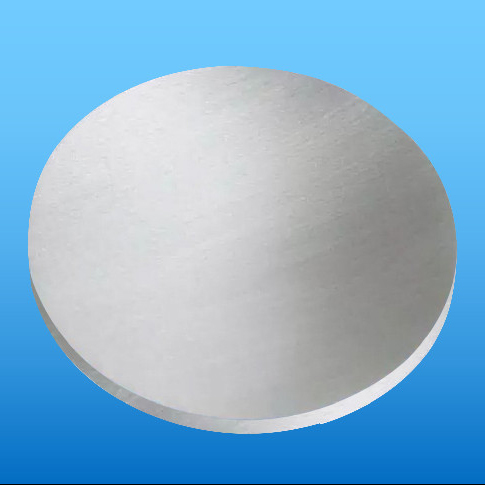

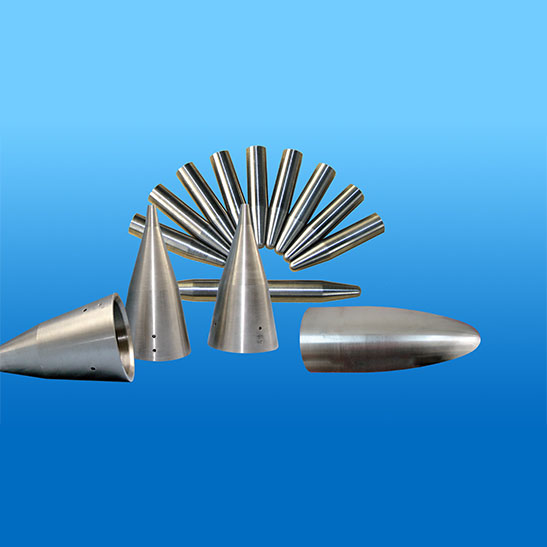

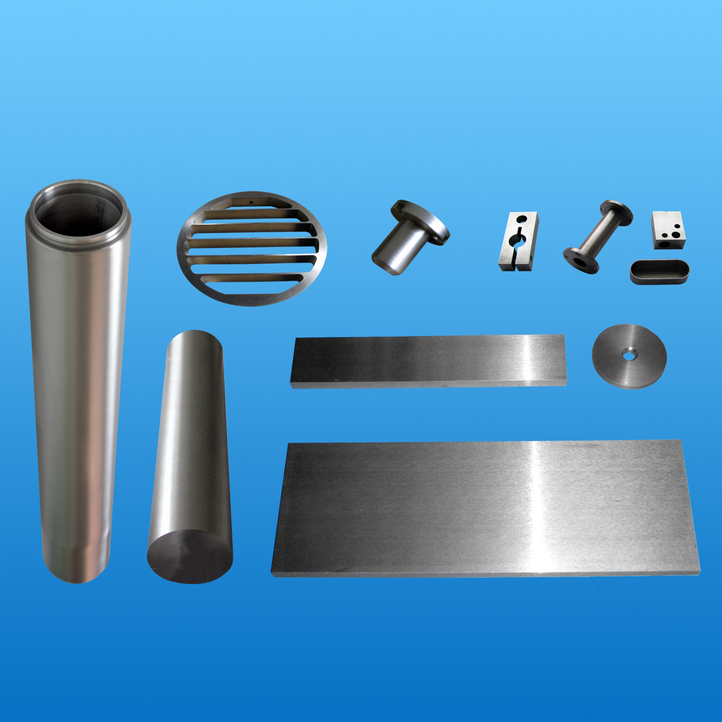

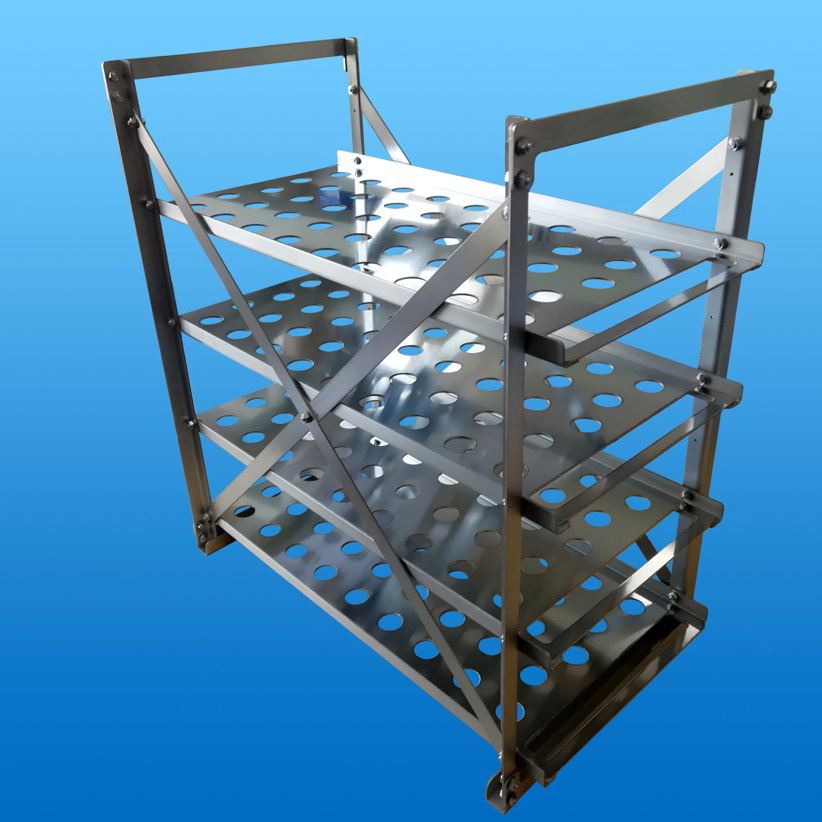

The conventional pure tantalum and pure niobium products (purity> 99.9%) are widely used for various high temperature and high vacuum heating elements and structural parts, sputtering targets, melting crucibles, chemical anti-corrosion, electronic components and other fields. Niobium alloy (NbZr1, Nb521, C103, etc.) has higher strength and high temperature performance than pure niobium, mainly used in aerospace engine parts and nuclear reactor structural parts. Tantalum alloy (TaW2.5, TaW10, TaW12, TaNb40, etc.) can significantly improve the strength and toughness while maintaining excellent ductility, widely used in chemical anti-corrosion, defense and military fields.

Tantalum (Ta) is bright, very hard, silver-gray metal, characterized by its high density, extremely high melting point, and excellent resistance to all acids except hydrofluoric at ordinary temperatures. Tantalum is chemically much like niobium because both have similar electronic configurations and because the radius of the tantalum ion is nearly the same as that of niobium as a result of the lanthanoid contraction. Tantalum is ductile, easily fabricated, highly resistant to corrosion by acids, and a good conductor of heat and electricity and has a high melting point. The major use for tantalum, as tantalum metal powder, is in the production of electronic components, mainly tantalum capacitors. Major end uses for tantalum capacitors include portable telephones, pagers, personal computers, and automotive electronics. Alloyed with other metals, tantalum is also used in making carbide tools for metalworking equipment and in the production of superalloys for jet engine components.

The pure niobium metal is soft and ductile; it looks like steel or, when polished, like platinum. Although it has excellent corrosion resistance, niobium is susceptible to oxidation above about 400° C (750° F). Niobium can best be dissolved in a mixture of nitric and hydrofluoric acids. Niobium in the form of ferroniobium is used worldwide, mostly as an alloying element in steels and in superalloys. Appreciable amounts of niobium in the form of high-purity ferroniobium and nickel niobium are used in nickel-, cobalt-, and iron-base superalloys for such applications as jet engine components, rocket subassemblies, and heat-resisting and combustion equipment. Completely miscible with iron, it is added in the form of ferroniobium to some stainless steels to give stability on welding or heating. Niobium is used as a major alloying element in nickel-based superalloys and as a minor but important additive to high-strength, low-alloy steels. Because of its compatibility with uranium, resistance to corrosion by molten alkali-metal coolants, and low thermal-neutron cross section, it has been used alone or alloyed with zirconium in claddings for nuclear reactor cores. Cemented carbides used as hot-pressing dies and cutting tools are made harder and more resistant to shock and erosion by the presence of niobium. Niobium is useful in constructing cryogenic (low temperature) electronic devices of low power consumption.

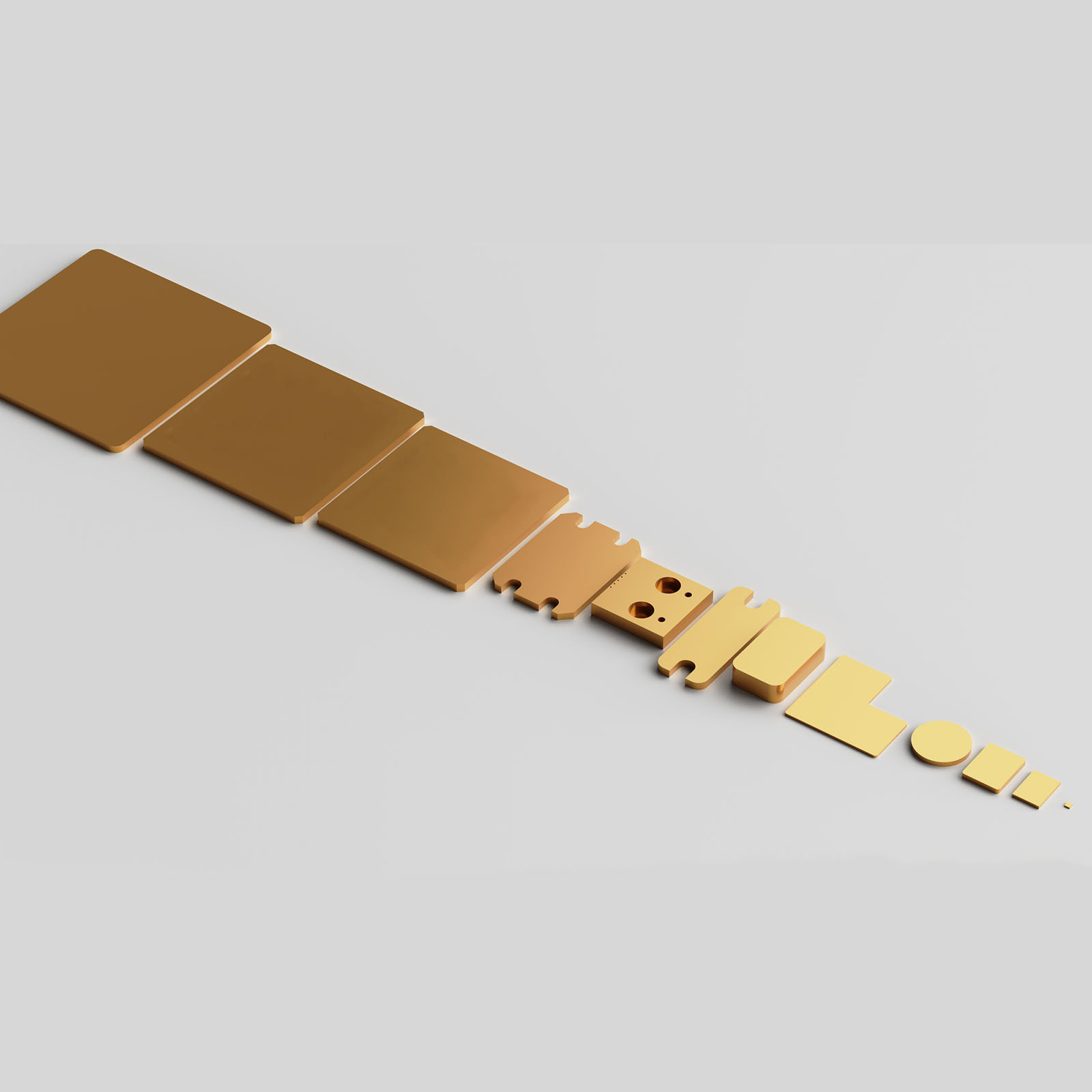

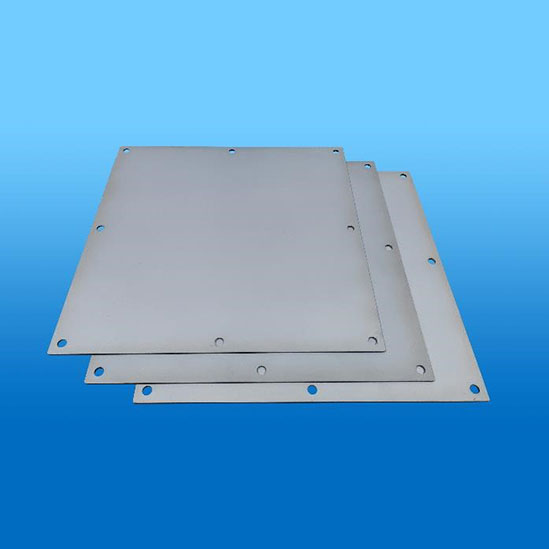

We can provide high-purity tantalum and niobium products with a purity of up to 99.995%, as well as composite plates of tantalum and niobium with copper, steel, kovar, etc.