Pure Molybdenum & Strengthened Molybdenum

Molybdenum Properties:

- High Density: 10.3 g/cm³

- High Melting Point: 2625°C (4760 °F)

- Low Vapor Pressure

- High Tensile Strength

- Low Coefficient of Thermal Expansion

- Low Electrical Resistivity

- Good Machinability

- High Absorption Capacity

- High Elastic Modulus

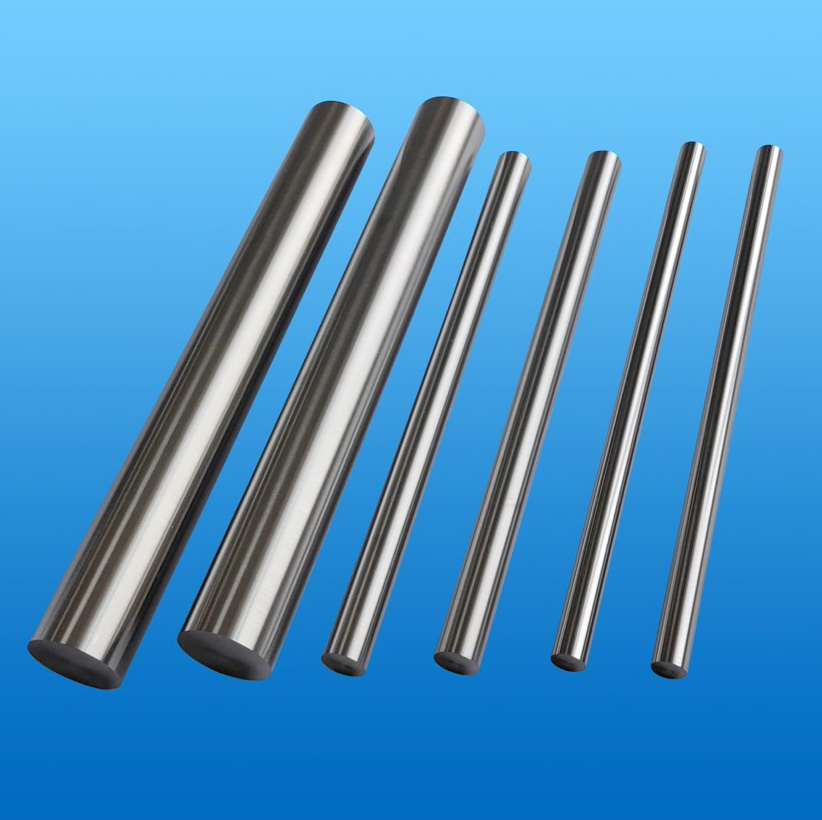

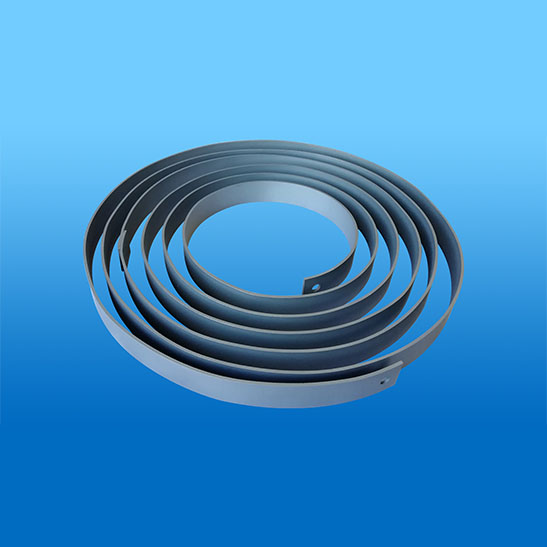

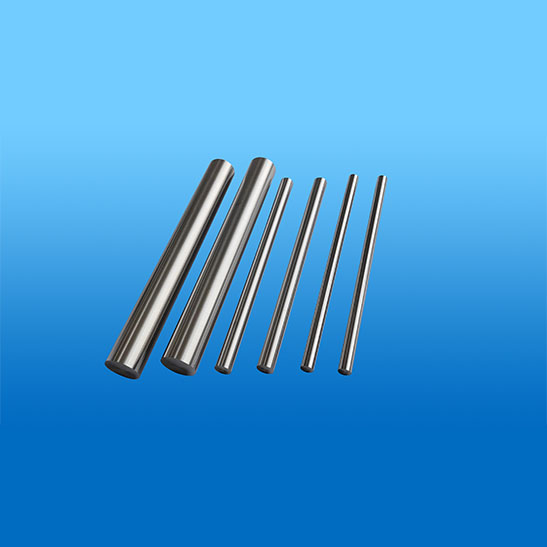

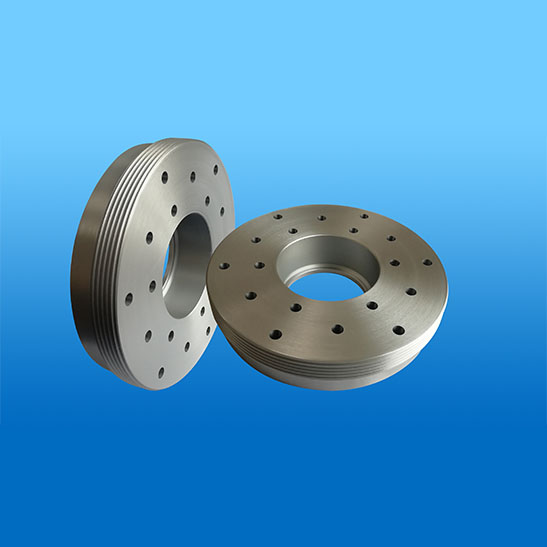

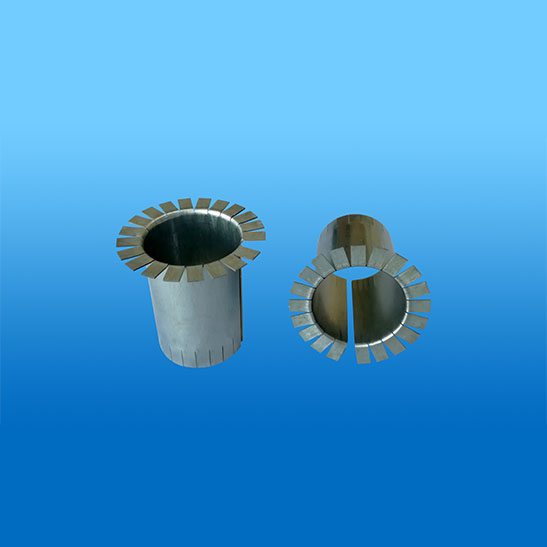

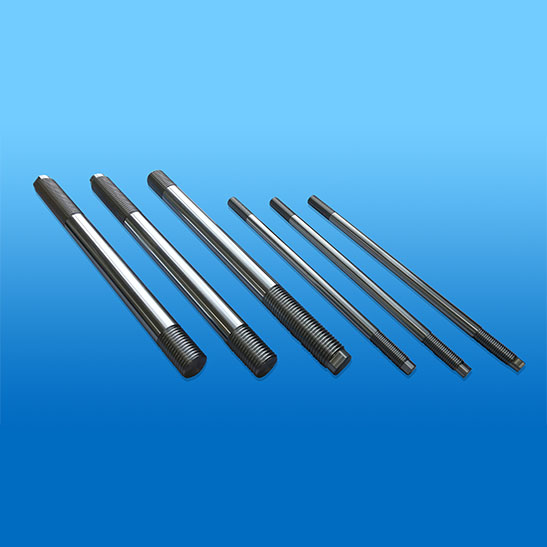

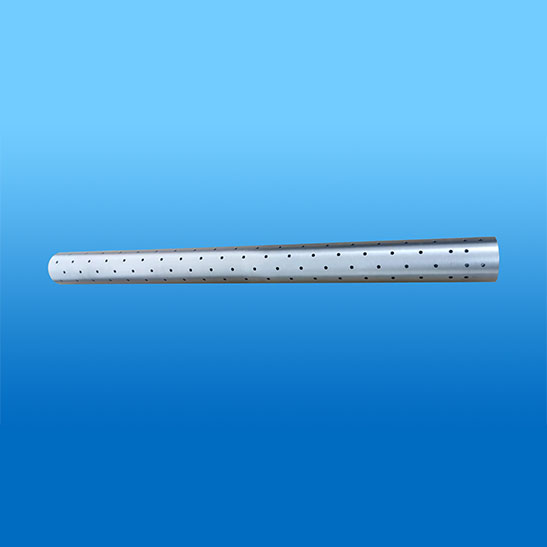

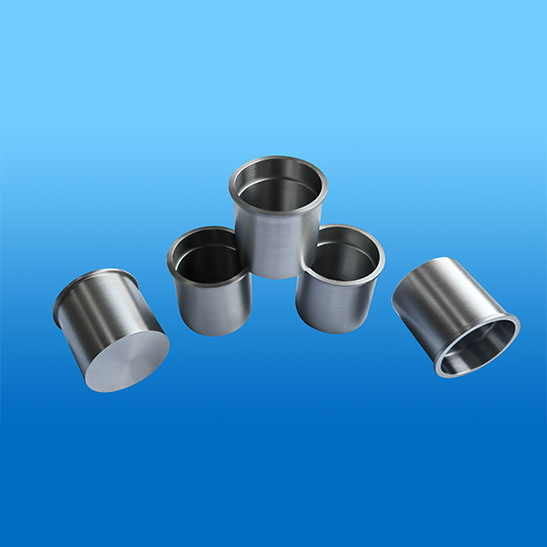

Molybdenum Applications:

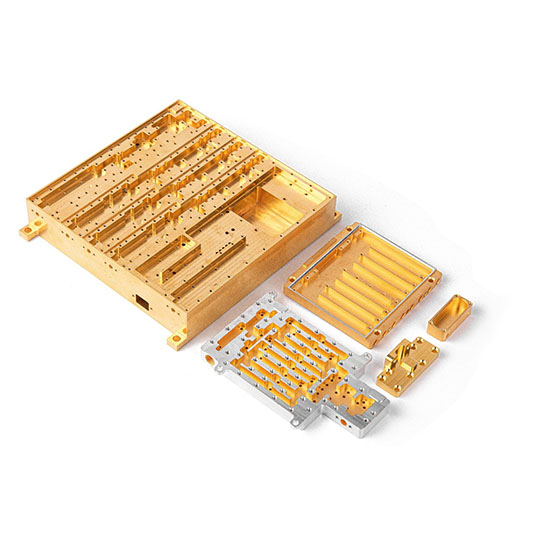

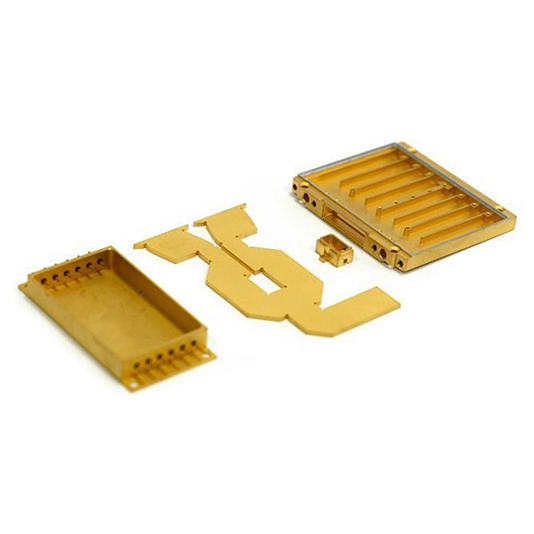

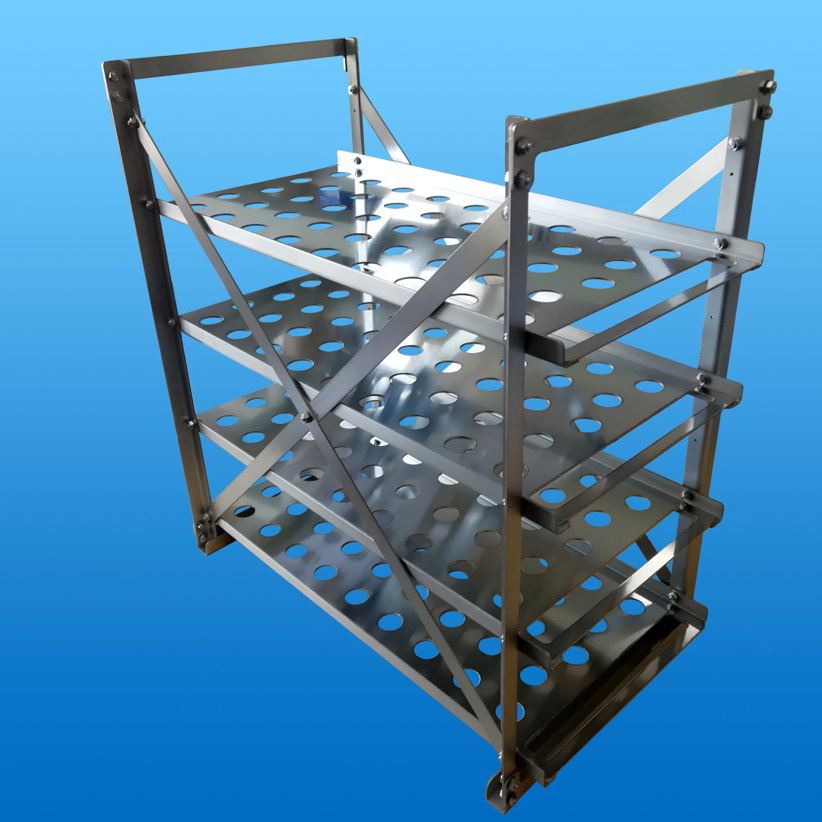

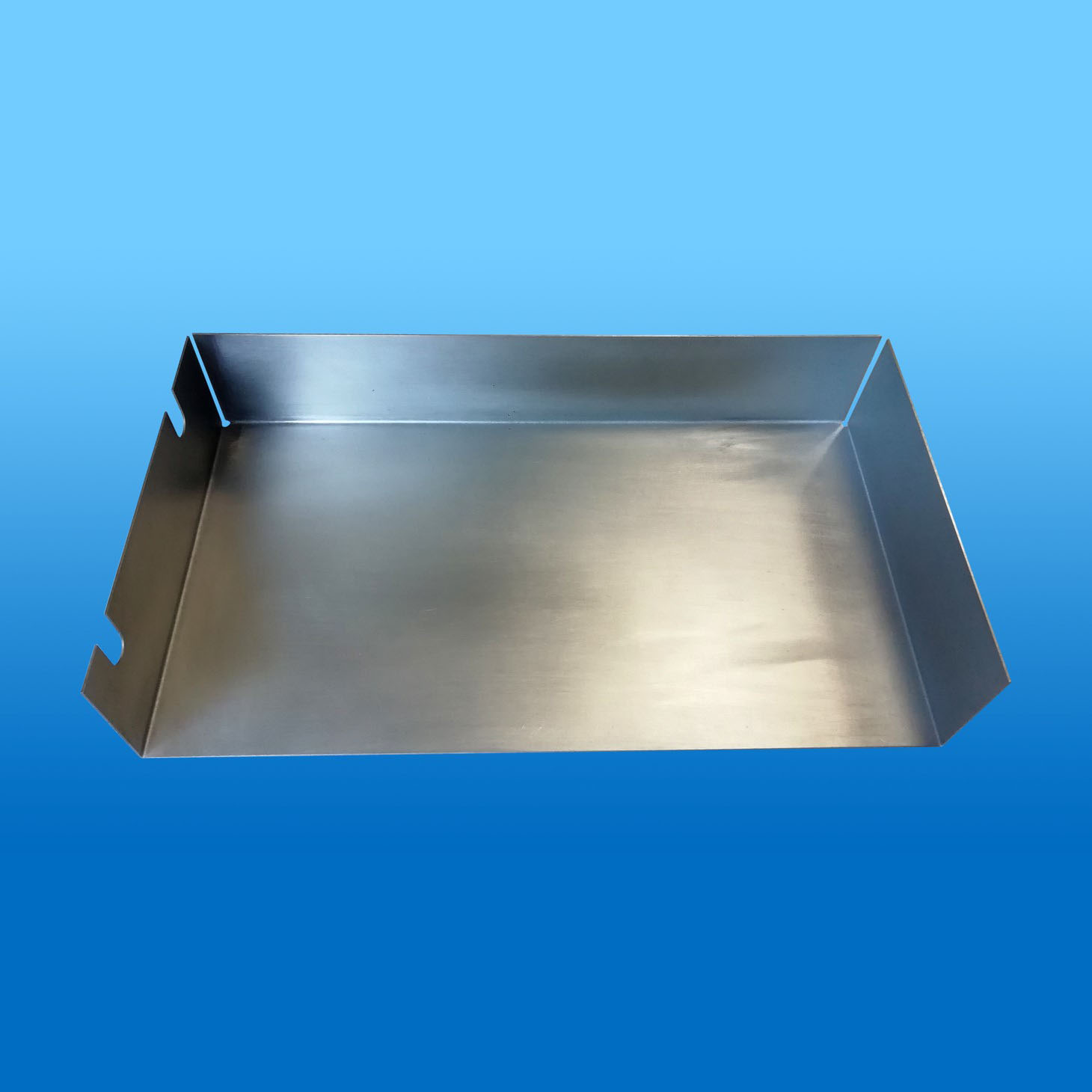

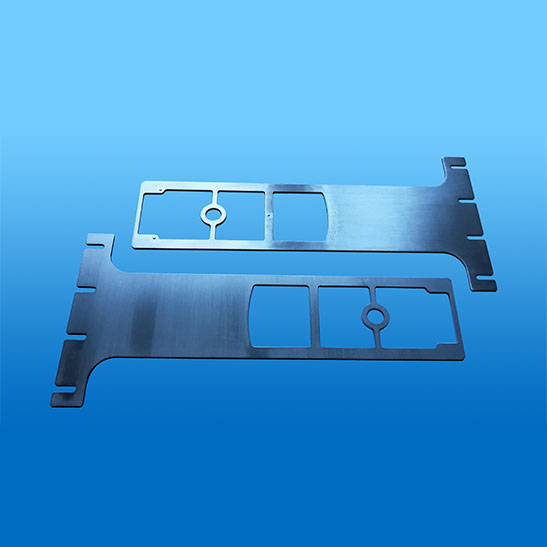

- Furnace Components

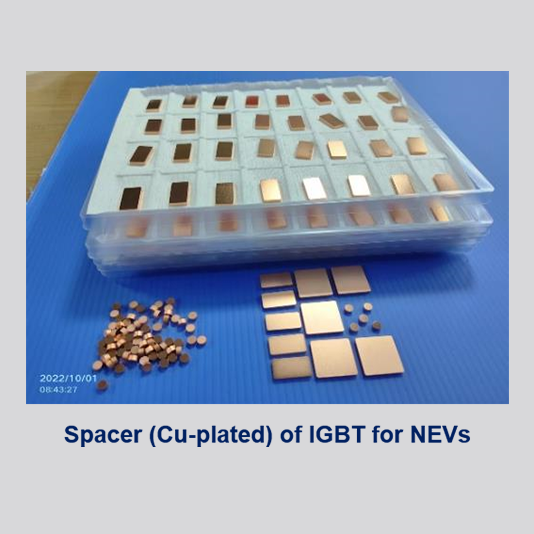

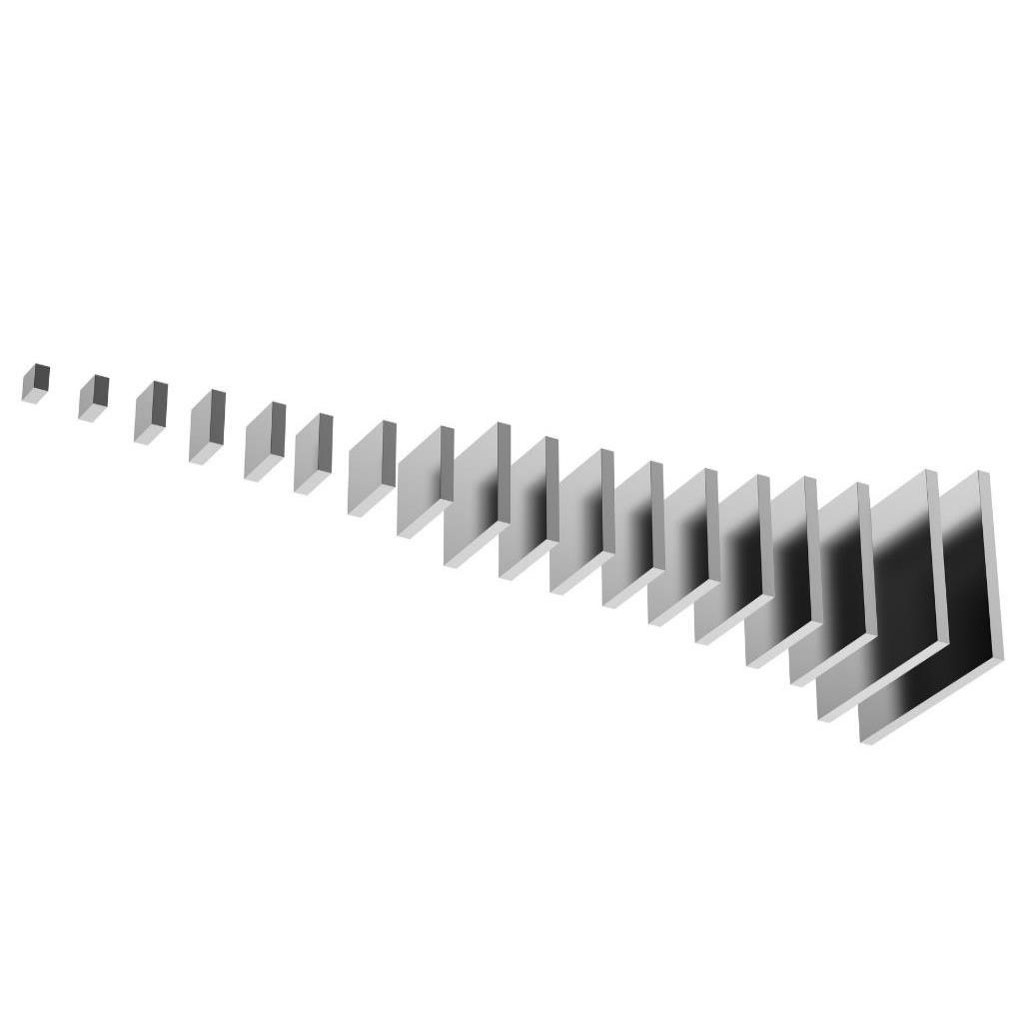

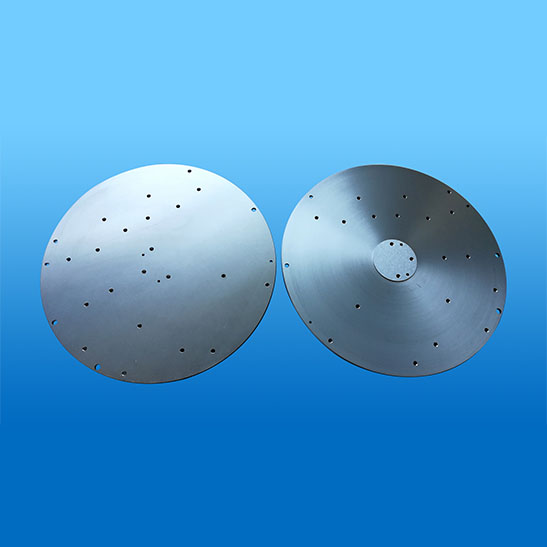

- Semiconductor Base Plates

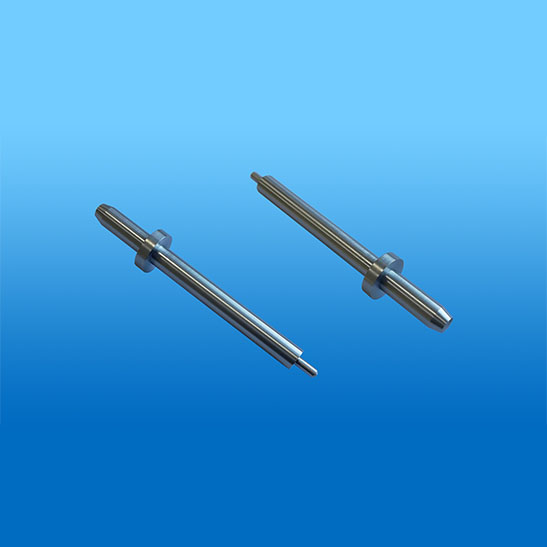

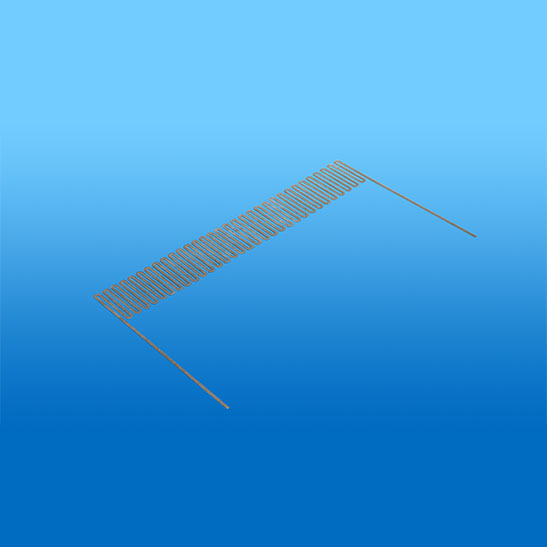

- Ion Implantation Cathodes And Anodes

- Sintering And Annealing Boats And Charge Carriers

- Radiation Shielding, Sputtering Targets and Electrodes

- Components for Electron Tubes

Both molybdenum and tungsten are classified as “heavy metals,” though “moly” has a lower density, making it better suited to many specialized uses. Of all the elements, molybdenum has the lowest coefficient for thermal expansion. This, along with its high strength and thermal conductivity, make it the first choice for numerous industries and applications including specialty steelmaking; aerospace; touch-screen tech; electronic/electrical; and military & defense.

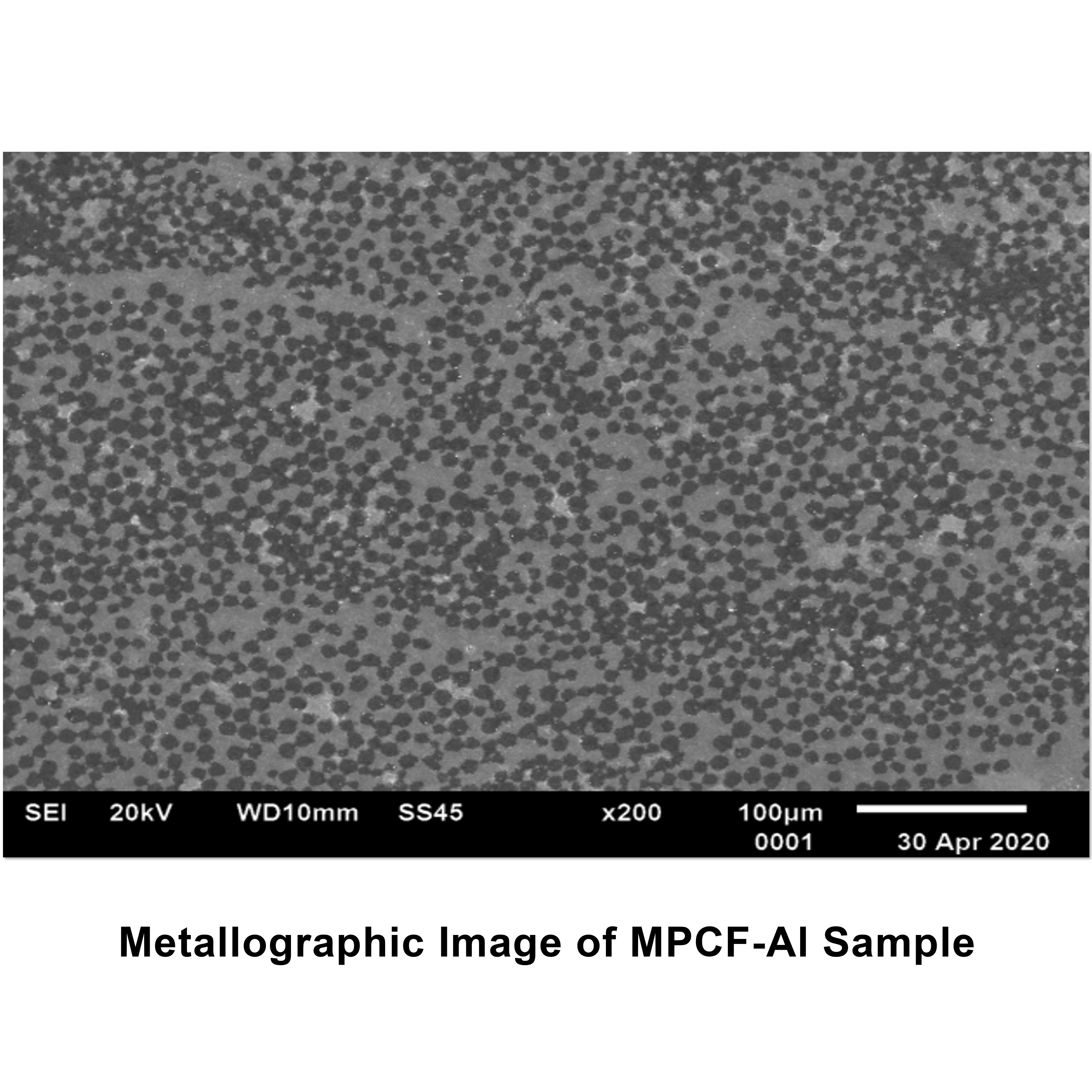

By adding Lanthanum into Molybdenum,Molybdenum Lanthanum alloyachieved a higher temperature recrystallization, a better ductility, and an excellent wear-resistant than molybdenum and TZM have.The recrystallizing temperature of Lanthanated Molybdenum alloy (Mo-La alloy) can rise to 1,500-1600 degrees Celsius from 1000 degrees Celsius which the pure Molybdenum can reach to. And the tensile strength can be up to 14000Mpa.

TZM(Titanium Zirconium Molybdenum) is a titanium-zirconium-carbon composite strengthened molybdenum material with outstanding strength properties below 1400°C and also has better wear resistance. It can be used for high-temperature and high-strength applications such as sintering plates, hot isostatic baskets, injection molding nozzles and other high-temperature and high-strength applications below 1400°C.

TZM is a molybdenum-based alloy containing 0.5% titanium, 0.08% zirconium, 0.03% carbon, and molybdenum makes up the balance. By combining small amounts of Ti and Zi, TZM alloy gains a high recrystallization temperature, making TZM twice as strong as pure molybdenum at 1300°C. The optimal doping percentages are 0.4–0.6% of titanium, 0.07-0.12% of zirconium, and 0.01-0.04% of carbon.

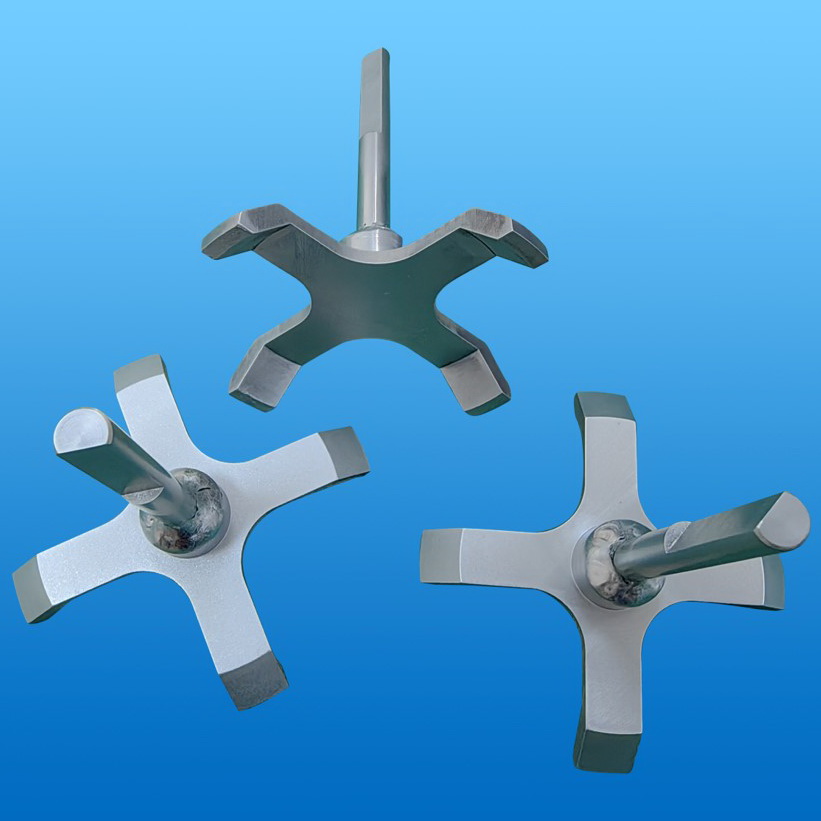

Titanium Zirconium Molybdenum (TZM) alloy is an ideal material for many industrial applications requiring high strength, high-temperature processes, including those common in the aerospace, electronics, and thermal treatment industries. TZM alloy is especially advantageous for work in the 700-1400°C range. TZM alloy is a versatile material for various high-temperature applications. It’s an excellent choice for metal casting molds that require durability, thermal conductivity, and low thermal expansion rates. TZM casting parts are dimensionally stable, resist cracking due to thermal stress, and withstand multiple high-temperature uses. TZM furnace components improve the capabilities of HIP furnaces, and TZM alloy is ideal for X-ray anode targets due to its high-temperature performance and corrosion resistance. TZM hot runner nozzles are an excellent choice for high-temperature, high-pressure injection molding processes, displaying outstanding resistance to heat, corrosion, and oxidation.

TZCis a molybdenum alloy with a higher carbon content of titanium and zirconium than TZM.

MHCis a hafnium carbide strengthened molybdenum alloy with higher strength than TZM. It can withstand the high temperature up to 1500°C.

Mo-W alloyusually has a Mo content of 50%-80%, and the rest is W. Its corrosion-resistant type is stronger than W and Mo alone, so it can be used as a zinc melting crucible and an agitator for glass production. Its better etching properties make it an excellent flat panel display target.