Tungsten Resources

1. Primary Resources

Tungsten deposits occur in each continent in the world. The most important and abundant tungsten deposits have been discovered in Southeast China and the Southeast Asian belt. There are also significant resources in the Central Andean belt, East Australian belt, Mesoproterozoic Karagwe-Ankole belt, and European Variscan belt.

According to the 2021 Mineral Commodity Summaries on tungsten by the US Geological Survey (USGS), the major tungsten-producing countries around the world are China, Vietnam, Russia, Mongolia, Bolivia, Austria, and Rwanda. However, compared with a decade ago, one significant change in the global tungsten supply and demand market is that the US completely stopped tungsten production in 2014 and now heavily relies on imports of tungsten.

In 2020, the global tungsten output was about 84 kt. Among major tungsten-producing countries, China remained the largest supplier. The production of tungsten in China accounts for more than 82% of the world’s production, reaching about 69 kt. More than 90% of Chinese tungsten resources are stored in the Nanling Range, which is located in Southeast China. There are more than 10 giant and more than 100 medium to small tungsten deposits in this range. Vietnam was the second-largest producer of tungsten concentrate, with a share of about 5% (4300 t), while Russia ranked third, with about 3% (2200 t), followed by Mongolia, Bolivia, Rwanda, and Austria, which produced over 1% of the world’s production (1900 t; 1400 t; 1000 t; and 890 t, respectively).

In 2020, the estimated global tungsten reserves were around 3400 kt. China accounts for about 1900 kt or more than 56% of the global total. Russia and Vietnam have the second (400 kt; 12%) and third (95 kt; 3%) largest tungsten reserves. This is followed by Spain and North Korea, with 54 kt and 29 kt (more than 1% of the global total). Austria and Mongolia represent less than 1% of the global reserves, with 10 kt and 4 kt, respectively.

Hard-rock deposits are the major sources of wolframite and scheelite. However, wolframite can also be recovered from placer deposits. At present, there is mass production of tungsten from skarn, vein/stockwork, porphyry, and strata-bound deposits. Only a small amount of tungsten production originates from disseminated, pegmatite, breccia, brine, and placer deposits.

2. Secondary Resources

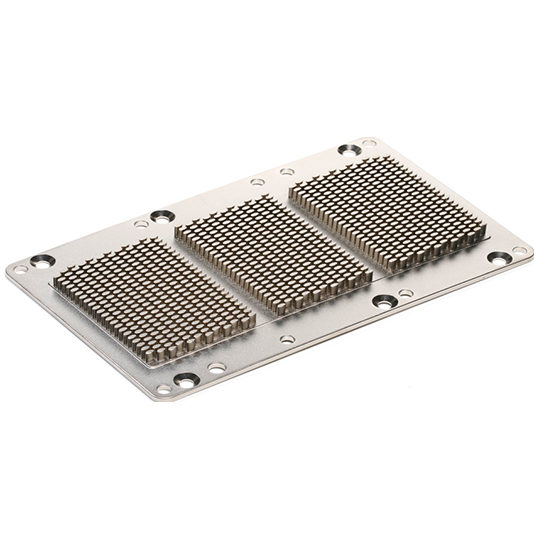

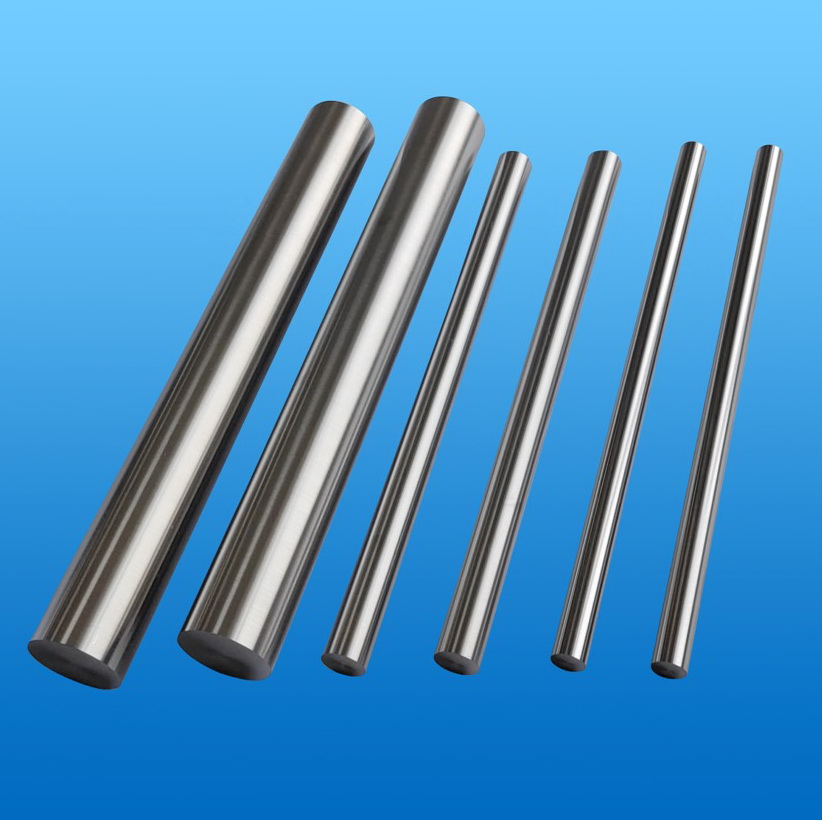

Currently, the only secondary resource of tungsten used in industry is tungsten scrap. It has already been used as a substitute for tungsten ore concentrates at conversion plants. Tungsten scrap (e.g., metal drill scrap, superalloys, and tungsten carbide products scrap, and powder metallurgical tungsten new scrap) could be divided into three types: new scrap (by-products of tungsten materials or products), old scrap (spent tungsten-bearing materials), and unrecovered scrap (excess reactants). The W grade of tungsten scrap is in the range of 40–95 wt.%. Since 2000, a wide variety of tungsten scrap recycling methods have been used globally. The methods to process tungsten-bearing scrap for tungsten recovery can be classified into four groups: hydrometallurgy, melting metallurgy, direct recycling, and semidirect recycling. Approximately 30% of world tungsten demand is met through tungsten scrap recycling.

Another possible secondary resource of tungsten is tungsten tailings. They are solid waste generated in the process of tungsten ores beneficiation. Because of the relatively low tungsten content in the ore, around 0.4–0.6% on average, the production of 1 t of tungsten concentrate (50–65% WO3) generates 7–10 t of tailings. The major components of tungsten tailings are typically SiO2, Al2O3, CaO, and Fe2O3, while W, Cu, S, Sn, Zn, Be, and Bi are the major trace elements. Much of the wolframite in tungsten tailings is below 25 µm, and the scheelite is below 74 µm [46]. Essentially, the remaining tungsten minerals in tailings are mainly in the fine and ultrafine fractions, which makes it difficult for reprocessing by conventional methods. Nevertheless, the incomplete statistics of tungsten tailings deposits around the world, presented in Table 4, indicates more than 100 Mt of tailings, containing about 96 kt of WO3. As a result, there may be a great potential for recovering tungsten from these unexploited secondary resources.

The total global mass flow of tungsten was estimated at 126.5 kt in 2010, including 102.5 kt of tungsten content in mined ores and 24 kt in the end-of-life tungsten scrap. However, about 30.3 kt of tungsten was lost in the waste streams during processing, including 4.7 kt in different residues (~5% processing loss) and 25.6 kt in tailings (~25% loss on recovery from mined ores). This also indicates a potential for recycling and further exploiting tungsten tailings as a secondary resource of tungsten.