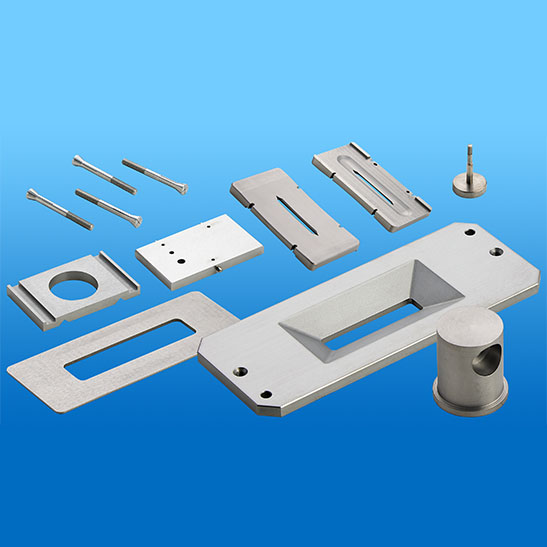

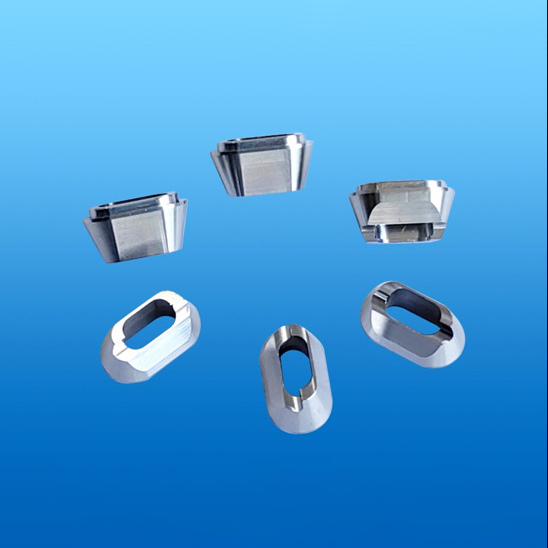

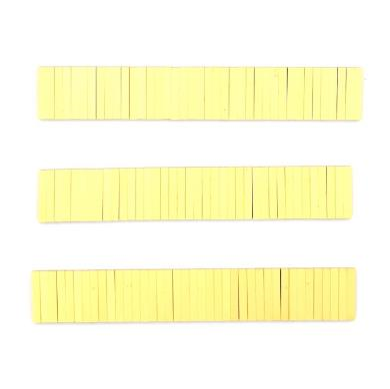

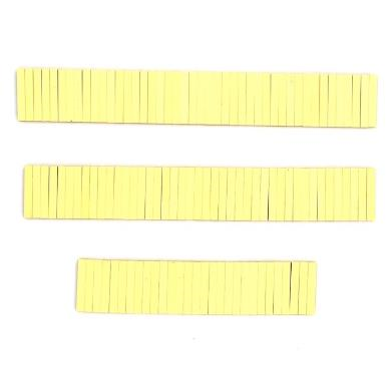

WCu Laser Bars

Product Advantages:

Reliable material quality: The WCu alloy we produce is almost completely compact, which is essential for thermal conductivity, stability of the CTE, as well as dimensional accuracy of appearance, reduction of surface and plating defects.

High machining accuracy: perpendicularity 90±0.5° or 0.01 mm, flatness 0.005 mm, surface finish Ra0.1 μm, dimensional tolerance±0.01 mm. With our unique processing technology, the surface machining grooves are not visible even under the high-power microscope.

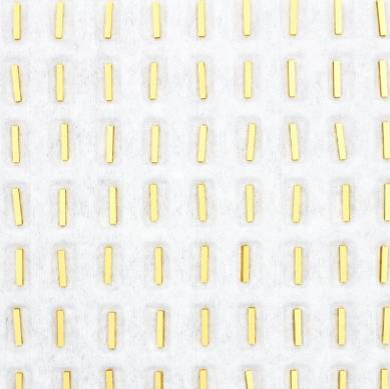

Reliable plating quality: There are two typical nickel and gold plating layers. (1) Nickel 1 μm + gold 0.3 μm. After nickel plating, there is no heat treatment, and gold plating is carried out directly. (2) Nickel 2-4 μm + Gold 0.5 μm. Nickel plating at the base is 1 μm, heat treatment is applied in hydrogen atmosphere at 800 °C for 10 min, and then nickel plating is thickened to about 3 μm, and gold plating is 0.5 μm. The thickness of the nickel and gold layers can be adjusted to meet the needs of customers. We can also provide quality services of selective spot gold/tin plating.

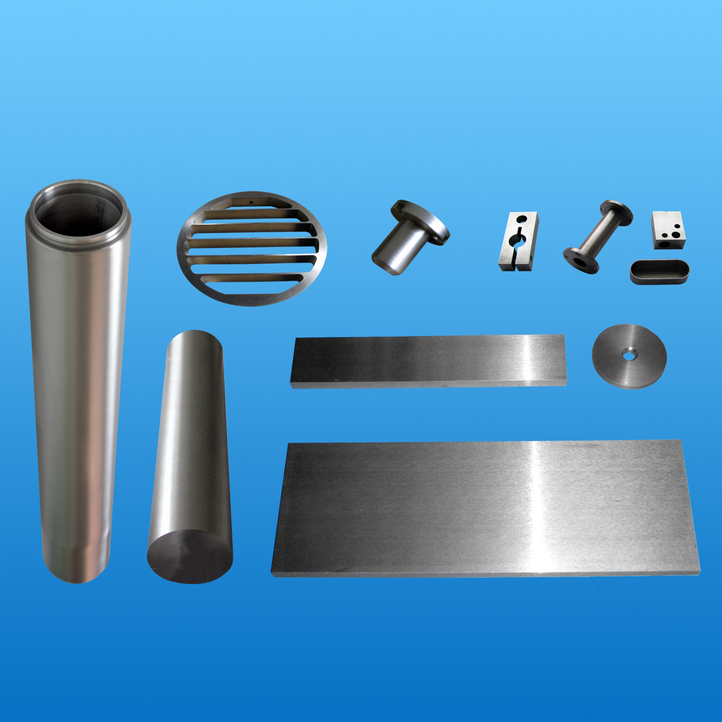

Material options and properties

Material | Mass percent composition | Density | Thermal Conductivity | CTE | |

With | IN | g/cm3 | w/m.k | 10-6/K | |

W93Cu7 | 7±1 | Balance | 17.6 | 150-170 | 6.0 |

W90Cu10 | 10±1 | Balance | 17.0 | 180-190 | 6.5 |

W85Cu15 | 15±1 | Balance | 16.4 | 190-200 | 7.0 |