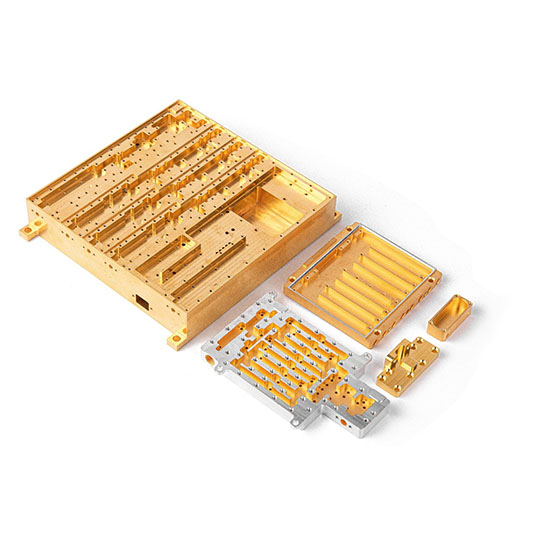

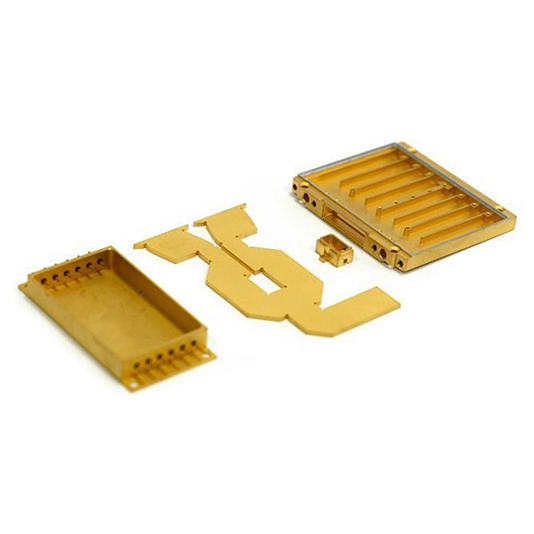

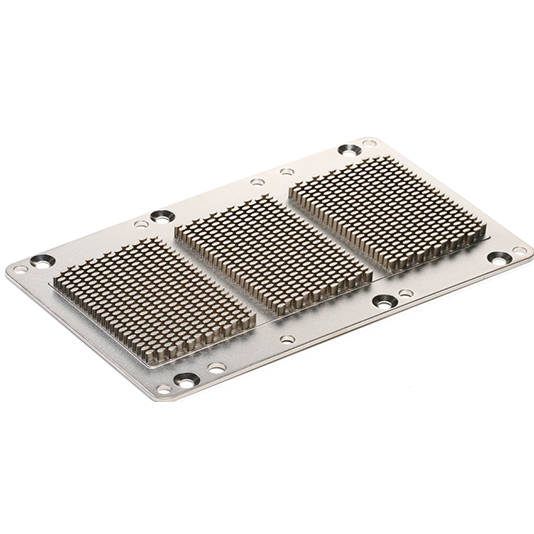

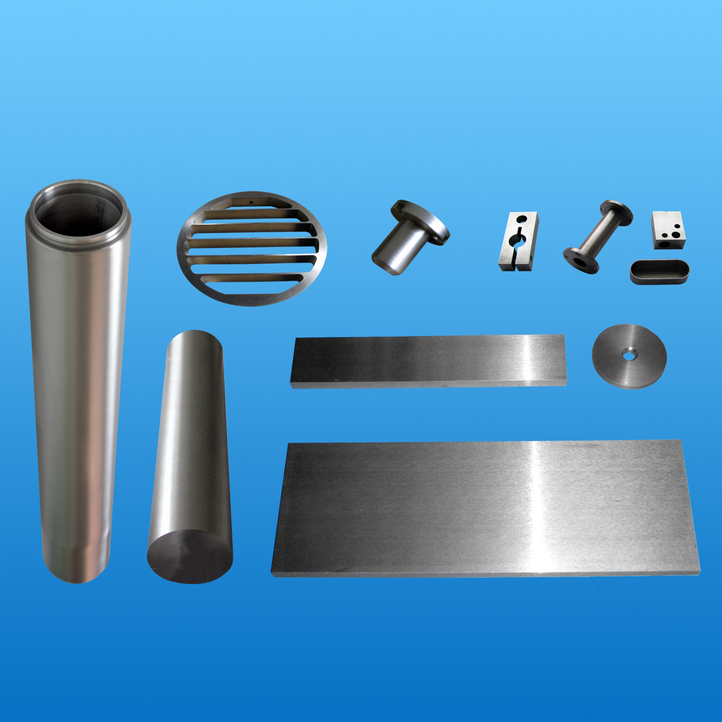

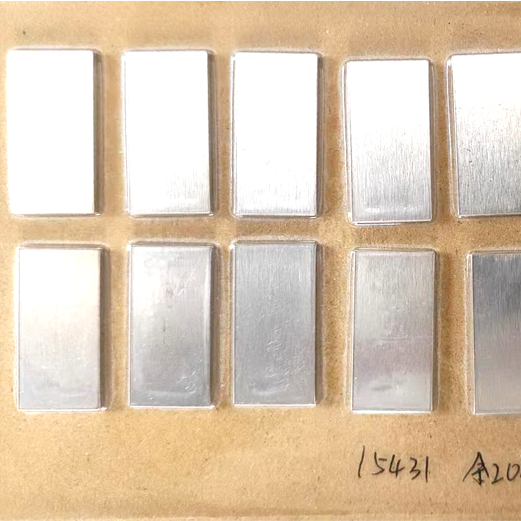

Molybdenum-copper alloy is also a pseudo alloy, molybdenum and copper are not miscible, fully combining the high thermal conductivity, high melting point and low coefficient of thermal expansion of molybdenum with the high thermal conductivity of copper. The ratio of molybdenum to copper can be adjusted arbitrarily, MoxCuy, x+y=100. The following table is just some of the commonly used grades. The molybdenum-copper alloy of Xingyao New Material can achieve almost completely dense, defect-free, fine-grained organisation, helium mass spectrometer leakage detection material airtightness <5x10-9Pa /m3.s, which is comparable with foreign products.

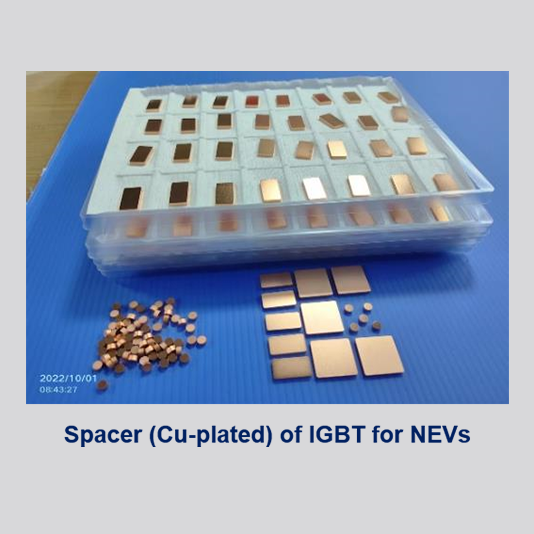

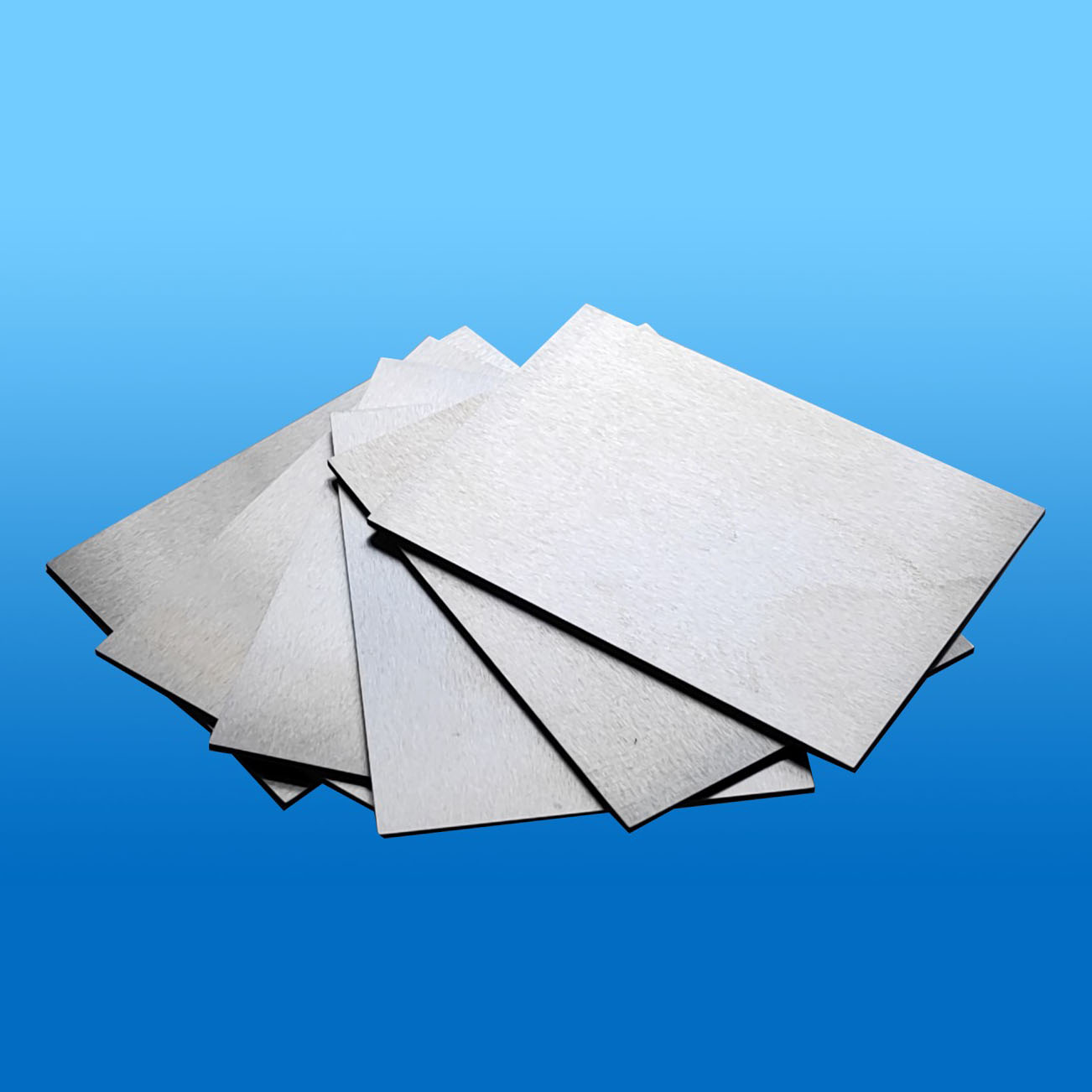

Compared with tungsten copper, molybdenum copper density is lower, rollability is better, suitable for the production of thin strip products; and molybdenum copper can be stamping, suitable for high-volume, low-cost production parts. Mainly used for electrodes, sweating materials.

We have decades of experience in producing all Mo/Cu composite ratios using either infiltration or solid sintering.

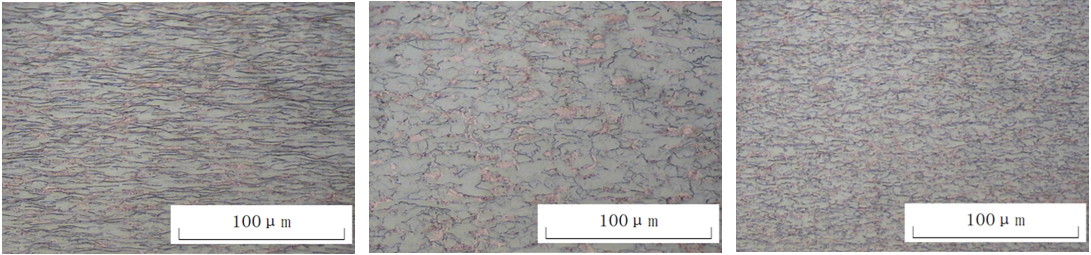

Infiltration sintering involves the molding and sintering of fine molybdenum powders into a porous skeleton structure. Next, capillary forces push the copper particles into the open area of the sintered molybdenum at temperatures exceeding 1100 o C. The infiltrated mixture then becomes a further condensed MoCu composite by further sintering, with a Mo volume fraction between 40% and 85%. The infiltration sintering improved microstructure homogeneity and porosity of MoCu composites, thus achieving higher thermal physical performance than possible in the solid sintering process.

Solid sintering is the conventional method for producing MoCu composites. It involves the mixing and compacting of fine powders of pure molybdenum and oxygen-free copper. The composites then go to the isothermal sintering process. The sintering is in an H₂/Ar environment at temperatures rising to 1150 o C. This process allows easy control of Mo and Cu weight fractions in the matrix composite. All processing stages have exacting standards and quality control. That ensures unsurpassed purity and precision in copper molybdenum materials.

Our advanced Mo Cu alloy materials can meet specifications as precise as 6-micron grain size, 0.01 mm porosity, and less than 5.0 x 10-9 Pa.m3 /s outgassing rate. The particle size and purity of these powders, the high temperature of sintering and annealing, and the deforming rates applied at each reduction are all under strict quality control and inspection protocols.

Home

Home