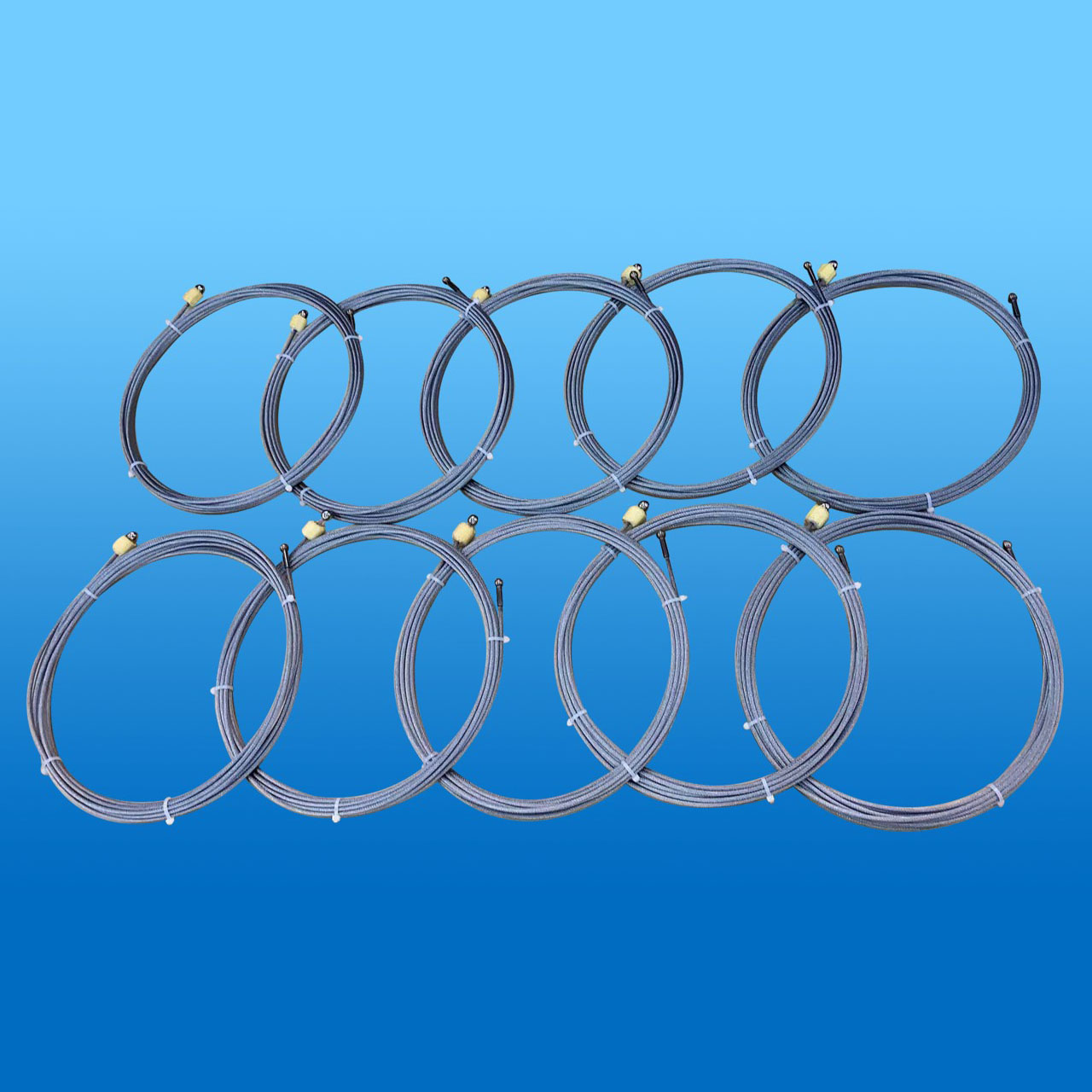

Tungsten Wire Rope

Tungsten Wire Rope or Tungsten Cable is characterized by high temperature resistance, wear resistance and tensile strength. In addition, due to its unique mechanical properties, tungsten has become an indispensable part in the manufacture of many cutting-edge medical devices (including surgical robots). It is mainly used in smelting and casting, single crystal furnace equipment, use of “flexible shaft” in the lifting system of monocrystalline silicon growth furnace and other smelting industries.

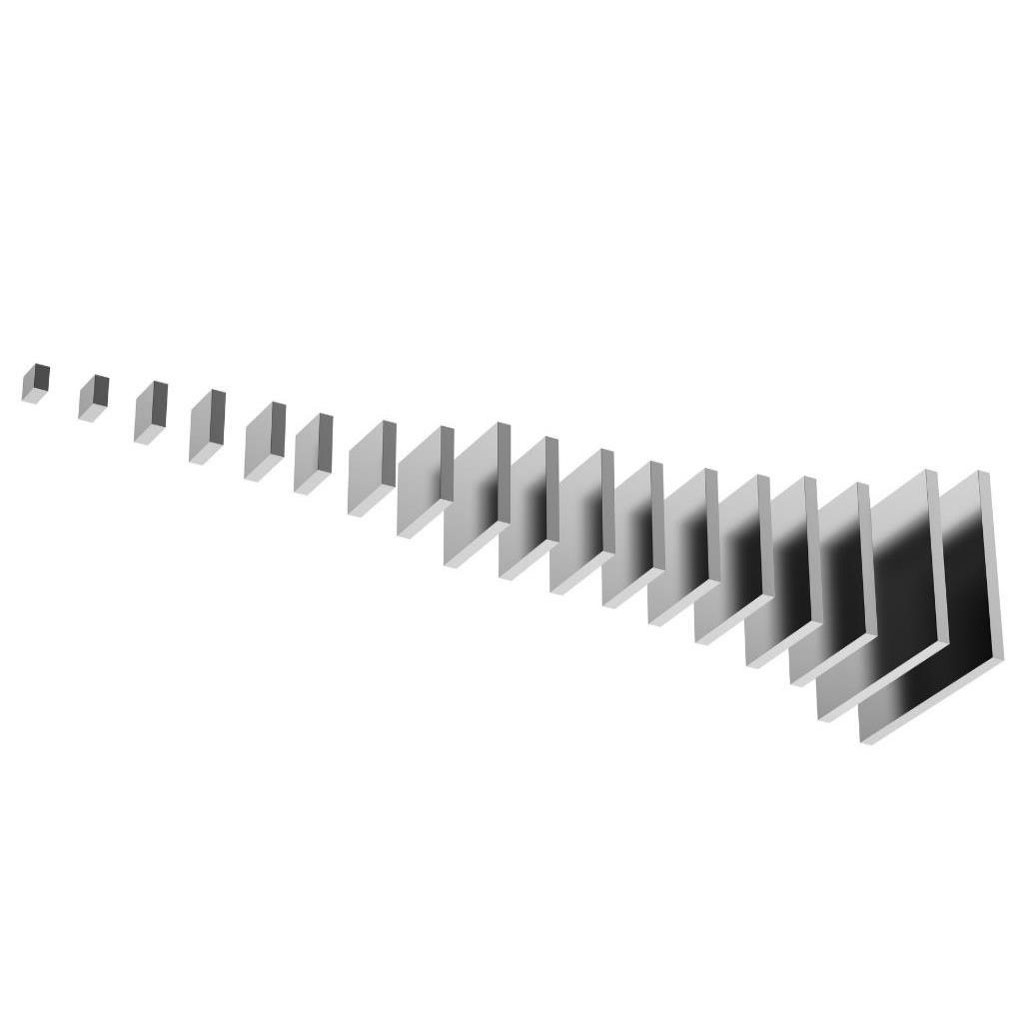

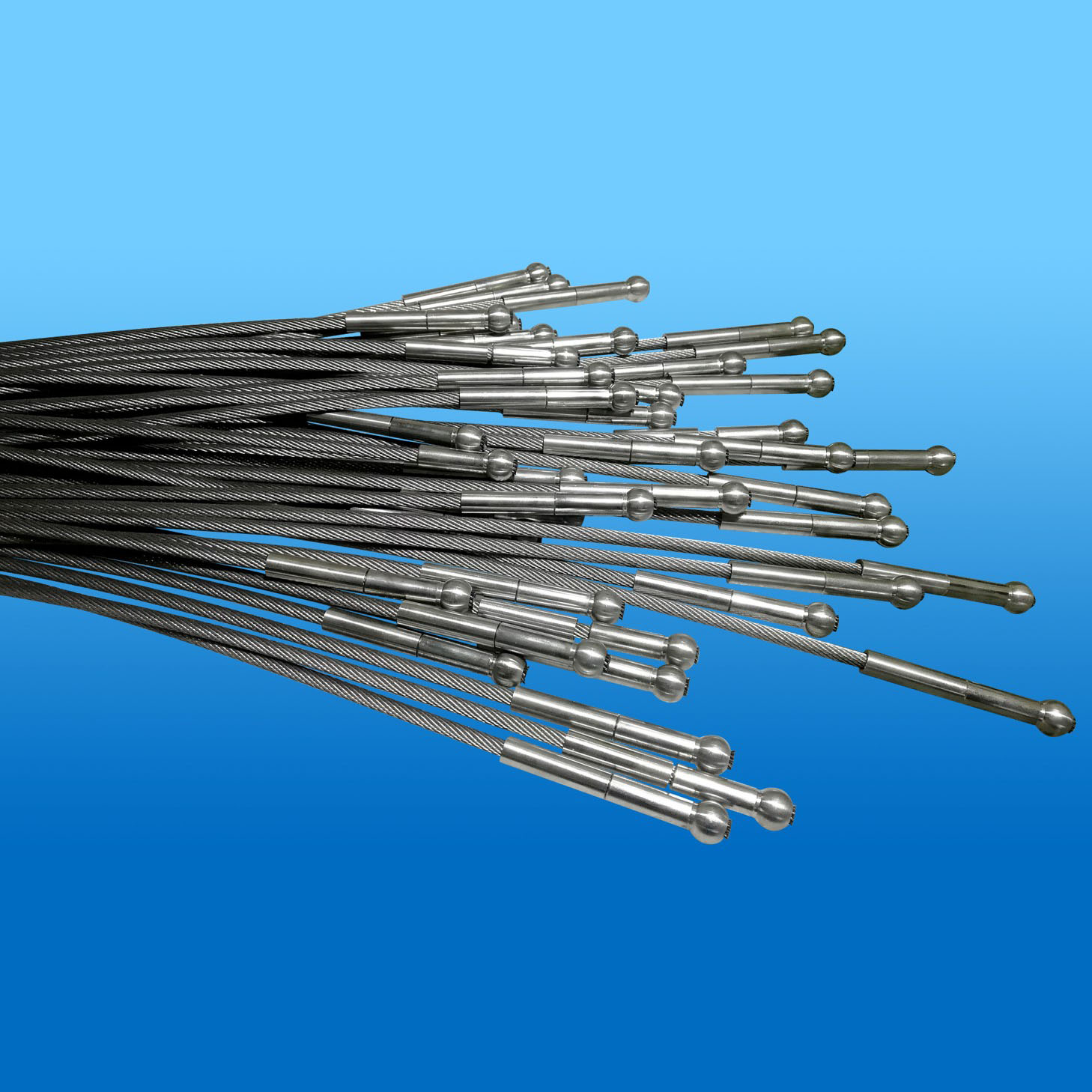

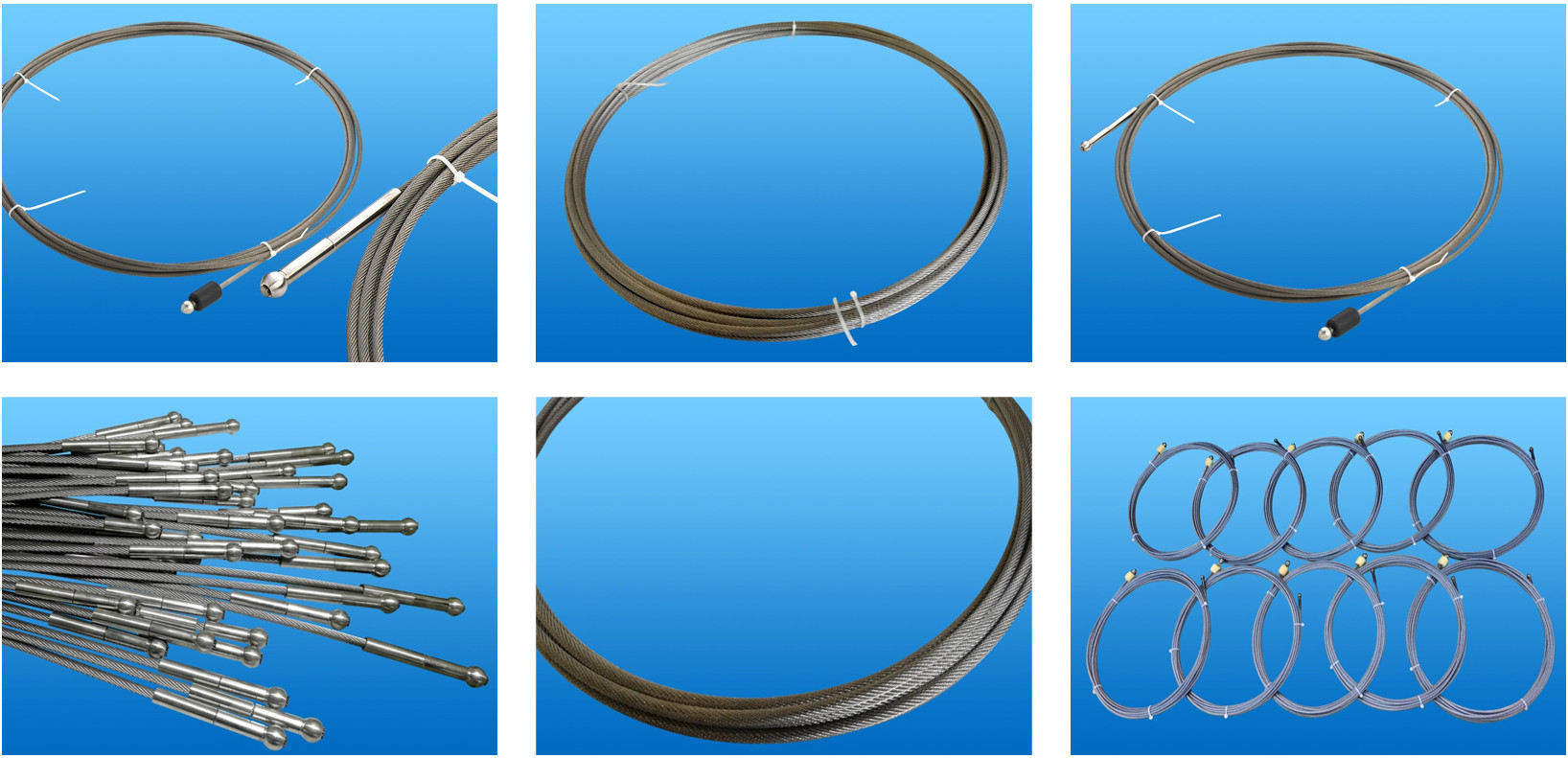

The Wire Rope has a complex structure with many individual wires combined together. It is important to know and select the characteristics of the rope required. By stranding multiple tungsten wires into a tungsten strand or rope, greater flexibility and dimensional stability is achieved. Multiple thin wires result in higher flexural fatigue strength, which means that a tungsten cable will not break as quickly as a single wire of tungsten. Compaction or hammering of the tungsten cable ensures that it is cut resistant and can be cut like a tungsten wire, keeping the individual wires together at the interface. Please refer to the table below to know more details.

Refractory metals such as tungsten have special properties compared to other metals. Tungsten offers high resistance to temperatures, chemicals and wear. It is ideal for use in high stress environments and offers a long service life under demanding conditions. Tungsten does not rust and is heavier than other metals due to its high density.

Tungsten wires, ropes and strands also have these properties.

With a melting point of over 3400 degrees Celsius, tungsten is one of the materials with the highest melting point. The high melting temperature is the reason for the high heat resistance of products made from tungsten. They are resistant and can withstand even extreme thermal conditions. No matter whether it is hot or cold, a rope or strand made of tungsten wire always retains its shape and function and is similarly resistant to corrosion as stainless steel.

Tungsten is one of the densest elements with a density of 19.3g/cm3, comparable to gold. A wire rope or strand made of tungsten is 2.5 times heavier than a rope made of stainless steel.

Products made of tungsten as a material are extremely resistant to deformation and breakage, which makes tungsten wire ropes and strands durable and reliable products. The higher strength in tungsten ropes results in a higher breaking strength compared to ropes made of stainless steel. Despite the high strength, tungsten cables are more flexible than stainless steel ropes. When used with pulleys, for example, a tungsten rope or strand is easier to guide over pulleys and small bending changes because it does not return to its original shape.

Tungsten is an excellent electrical conductor and its high conductivity makes it ideal for applications where efficient current transmission is required and there is a large amount of heat exposure. This makes tungsten wire an excellent choice for use in the electrical industry, e.g. in the manufacture of light bulbs or electrical heating elements.

With our high-quality tungsten wire ropes and strands, you can count on particularly high load-bearing capacity and durability. They are ideal for use in demanding applications where absolute reliability is essential. As a renowned manufacturer of tungsten ropes and strands, we also offer you a high degree of flexibility in designing your individual solution.

| Model | Unit | XY-40 | XY-45 | XY-50 | XY-55 | XY-60 | XY-65 | XY-70 |

| Material | / | W | W | W | W | W | W | W |

| Outer Diameter (O.D.) | mm | 4.0 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 |

| Tolerance O.D. | mm | ±0.15 | ±0.15 | ±0.15 | ±0.15 | ±0.15 | ±0.15 | ±0.15 |

| Rope construction | / | 19×7 | 19×7 | 19×7 | 19×7 | 19×7 | 19×7 | 19×7 |

| Strand direction | / | ZS | ZS | ZS | ZS | ZS | ZS | ZS |

| Breaking load at room temp. | N | 14480 | 18252 | 22381 | 26107 | 30037 | 32772 | 36104 |

| Breaking load at 1000℃ | N | 6545 | 8235 | 10209 | 11570 | 12975 | 14534 | 15962 |

| Load of safe use at high temp. | Kg | 550 | 650 | 750 | 850 | 950 | 1050 | 1150 |

| Minimum sheave diameter | mm | 120 | 135 | 150 | 165 | 180 | 195 | 210 |

| Atmosphere | / | Vacuum, hydrogen or inert gas | ||||||

| Expected service life | Month | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

Home

Home