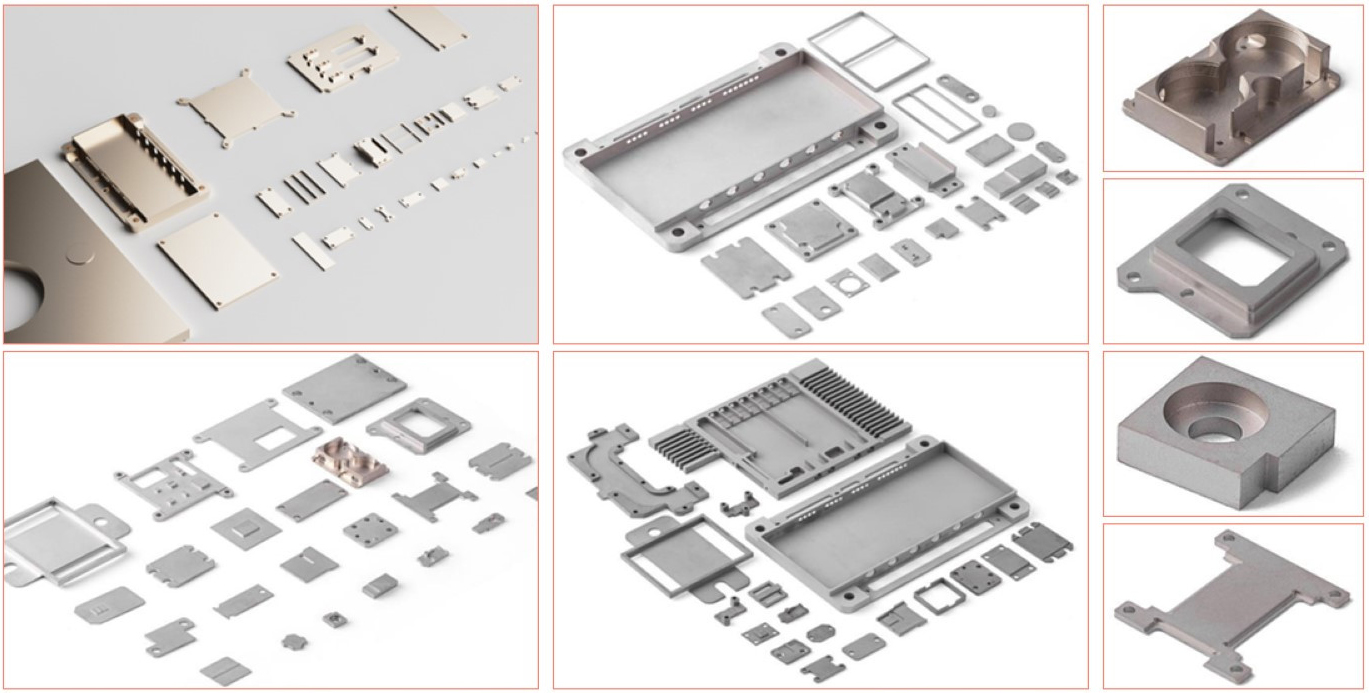

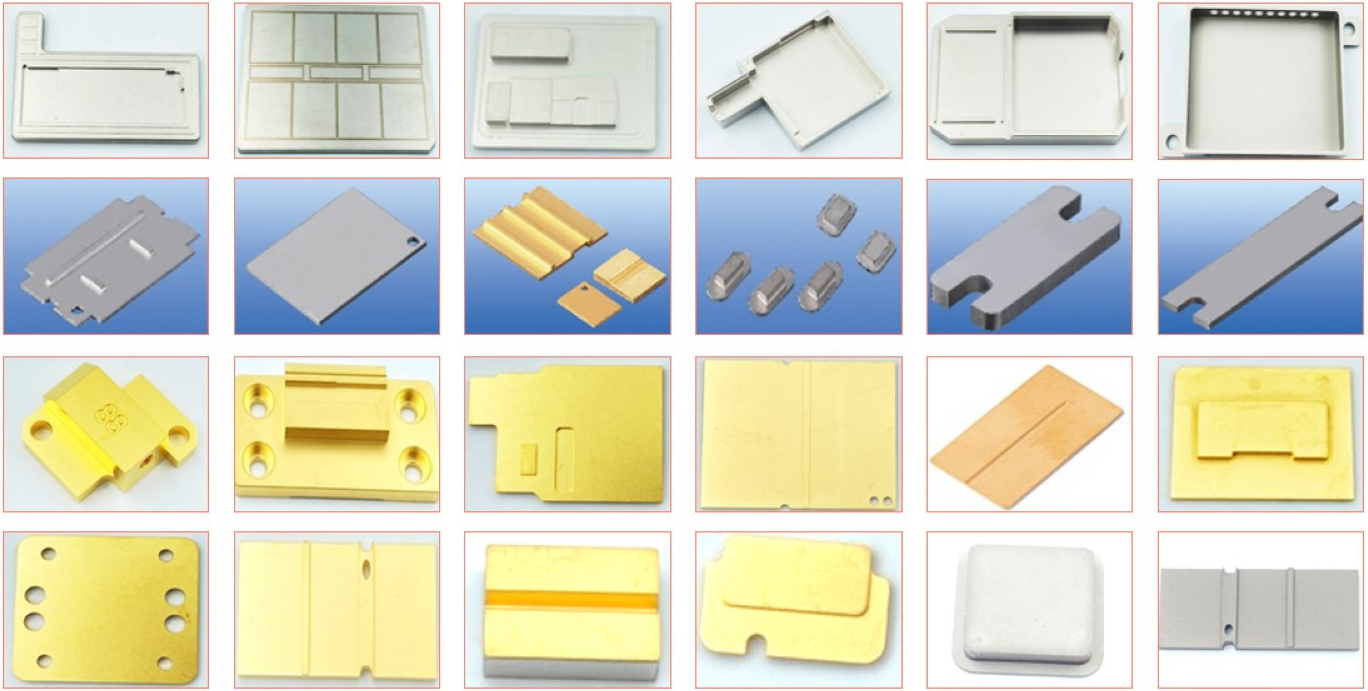

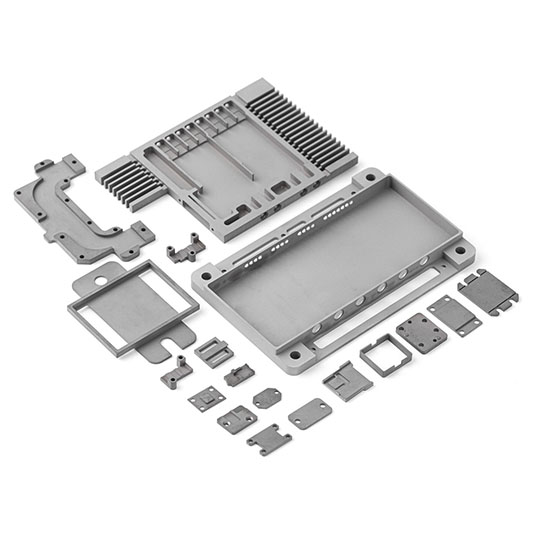

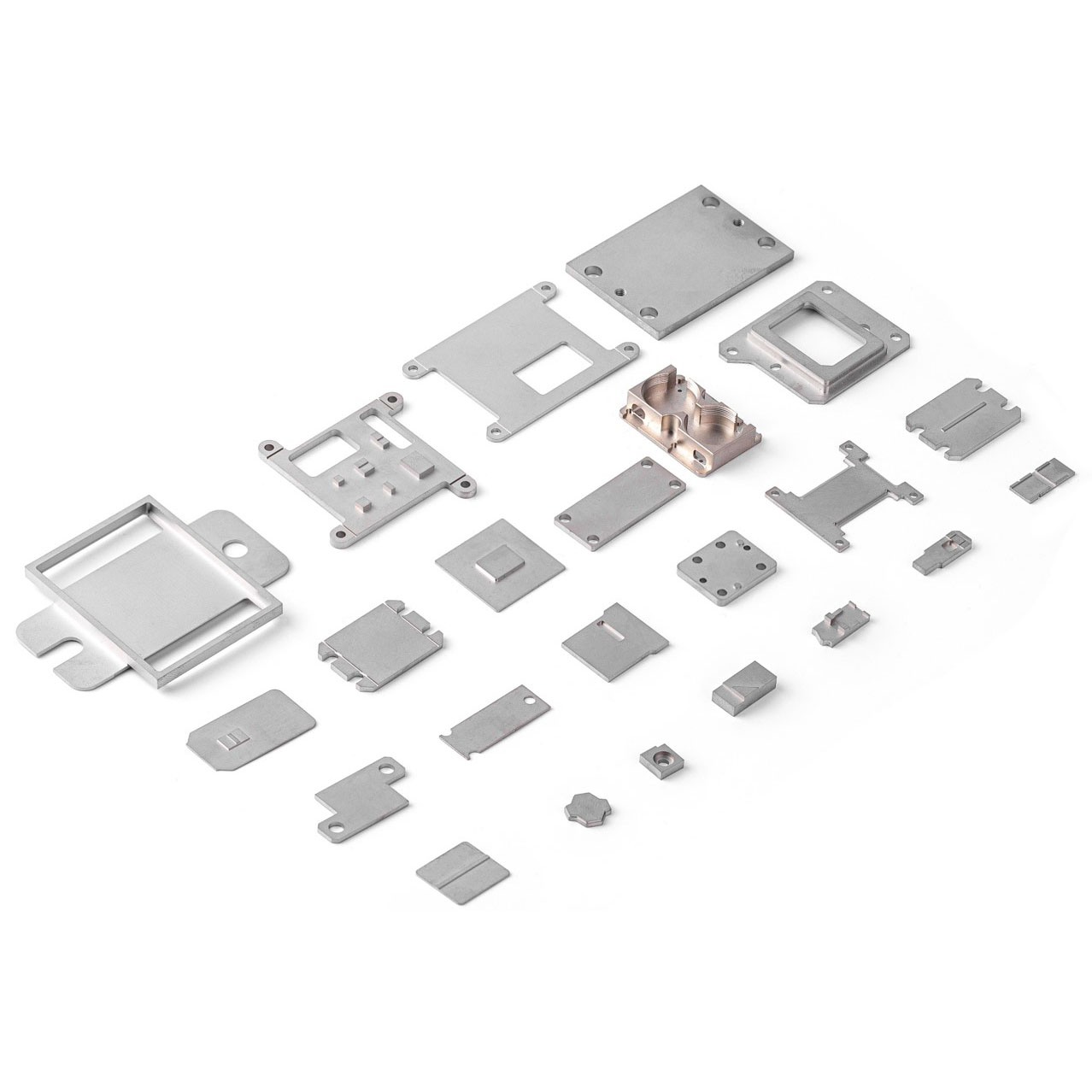

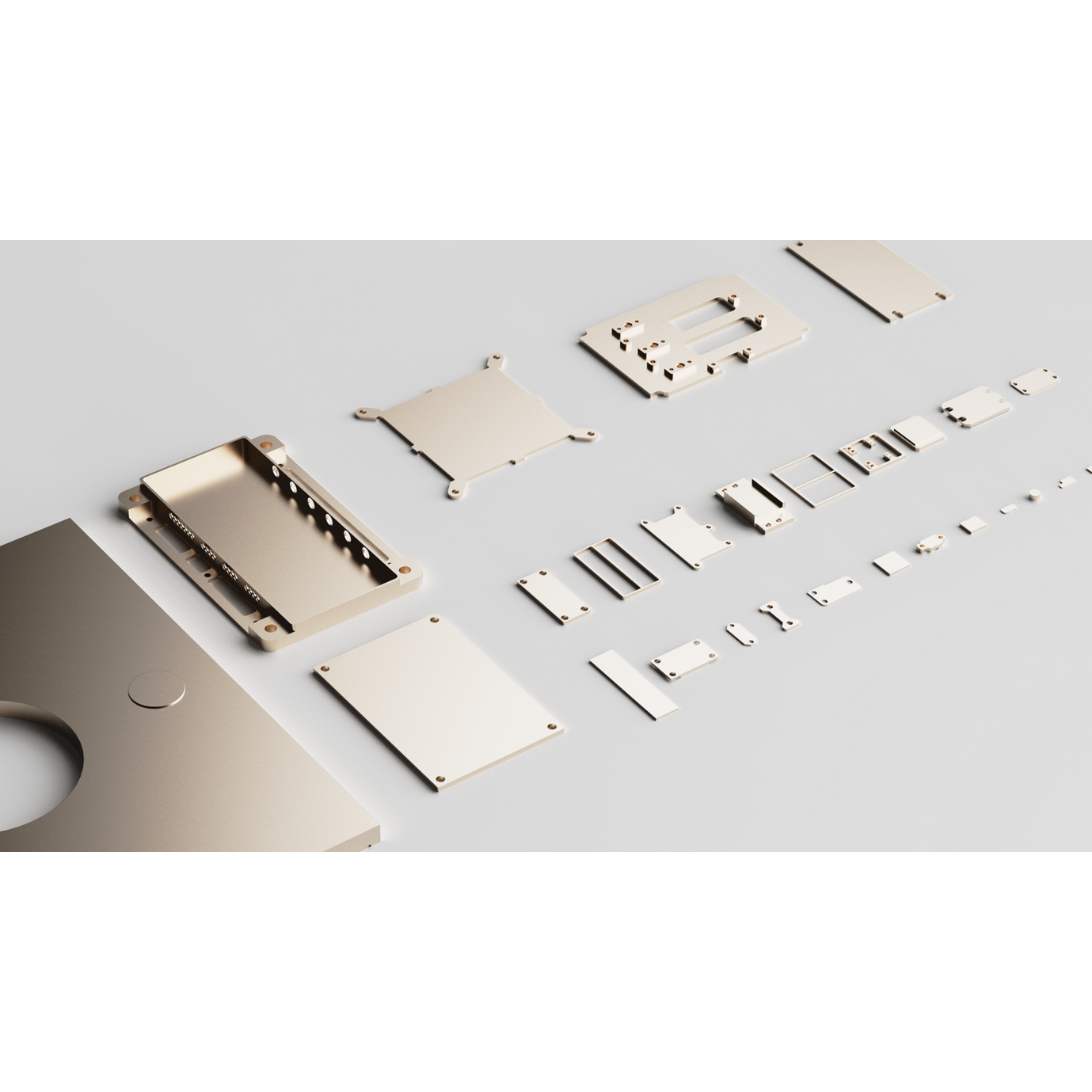

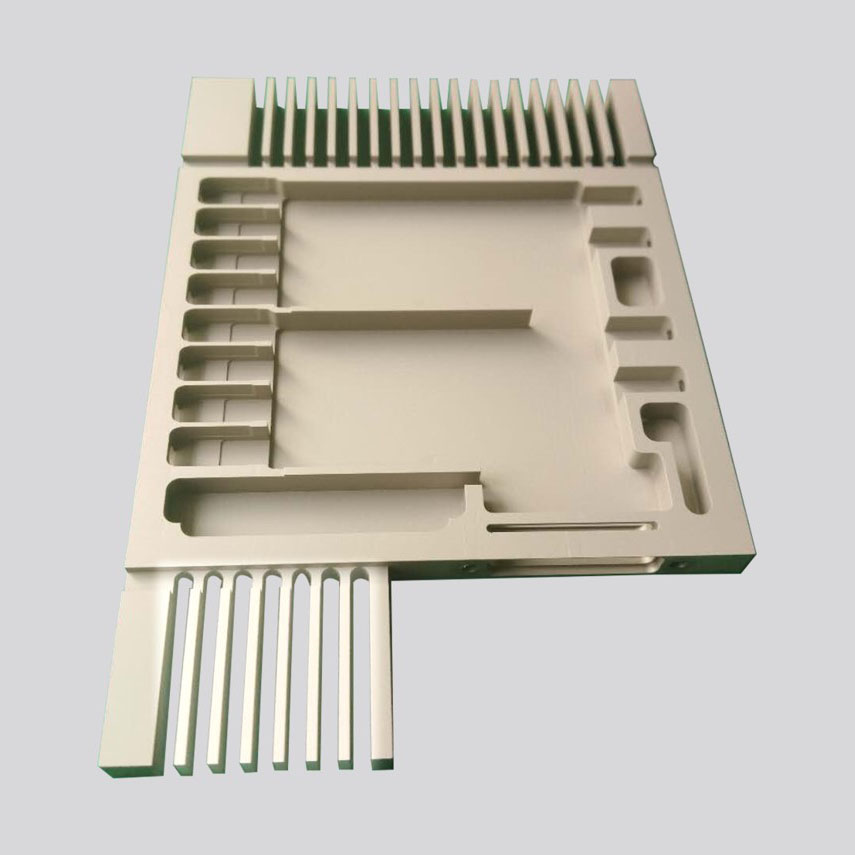

Molybdenum Copper heatspreader

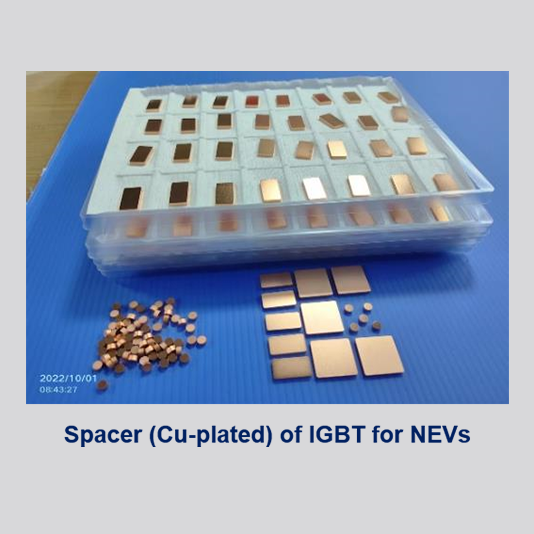

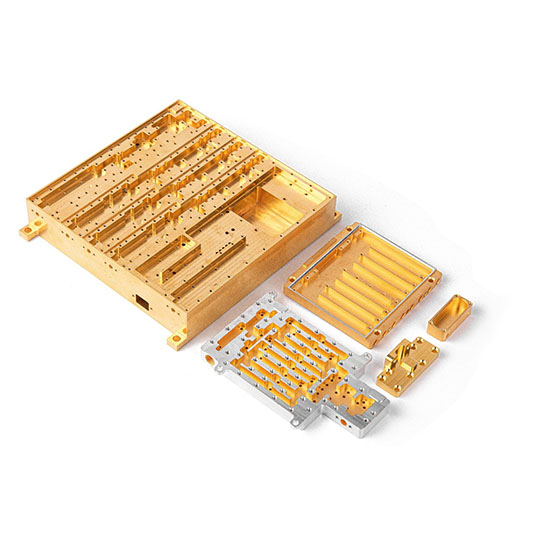

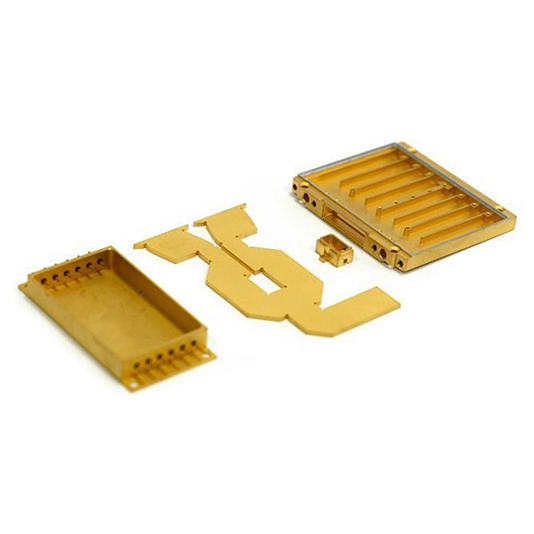

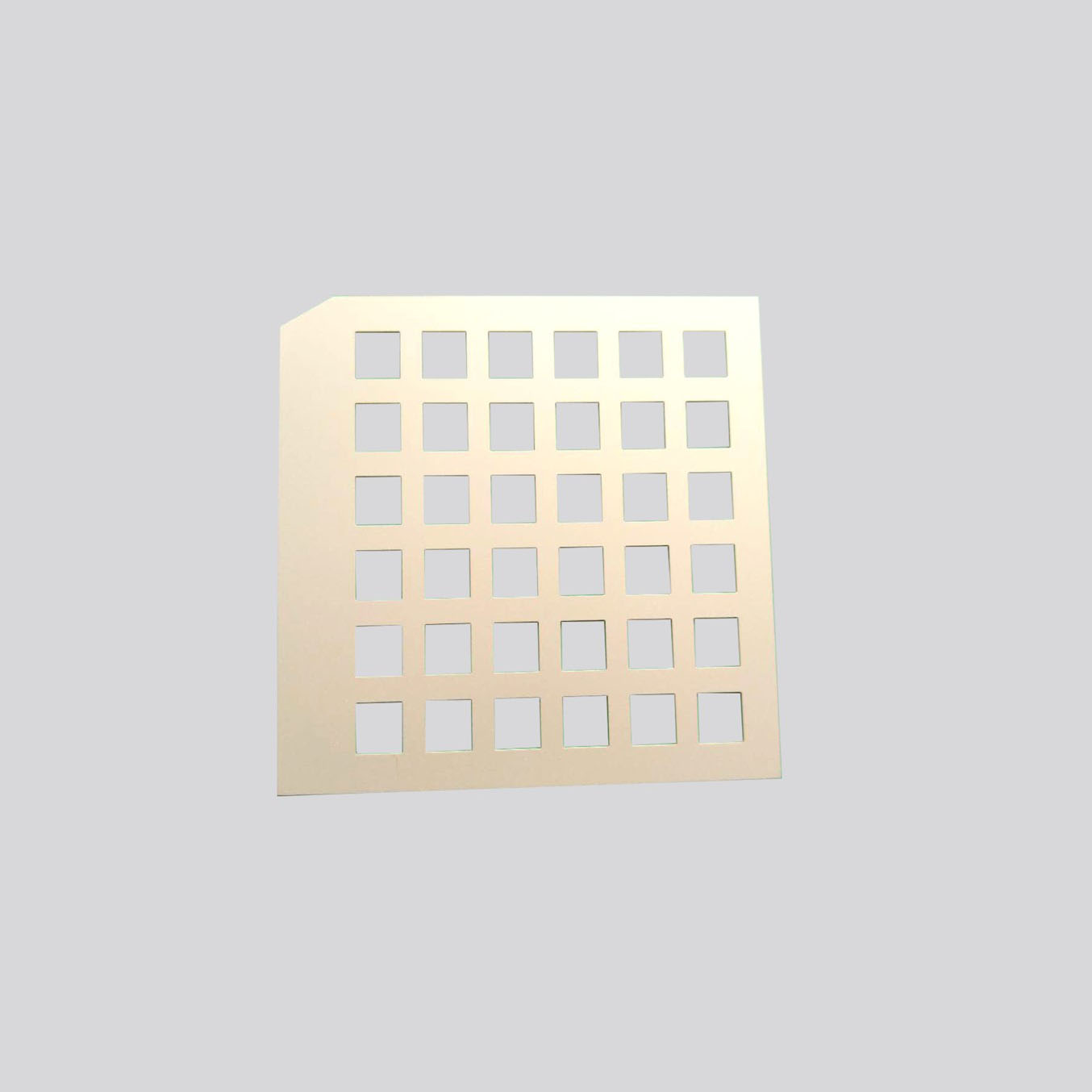

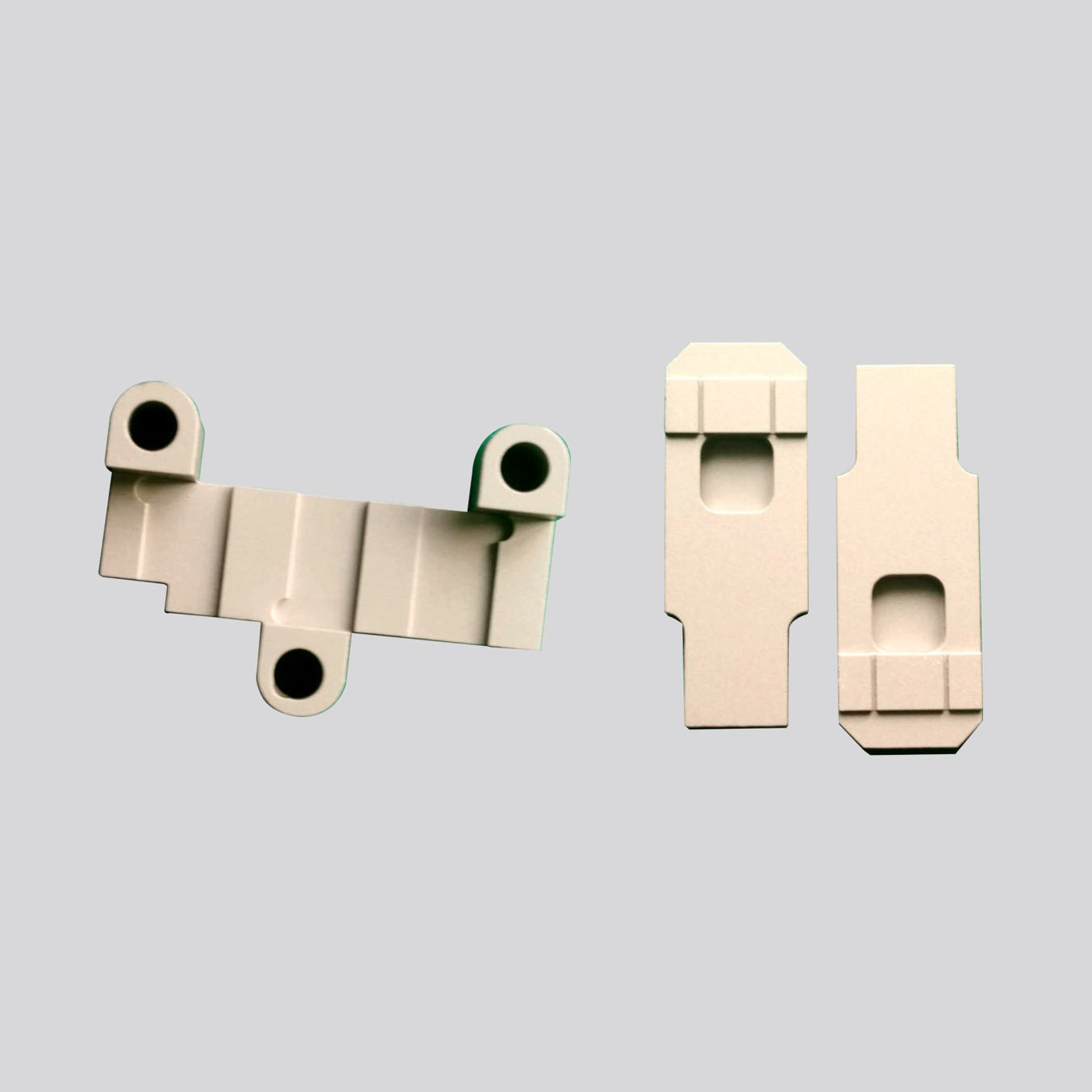

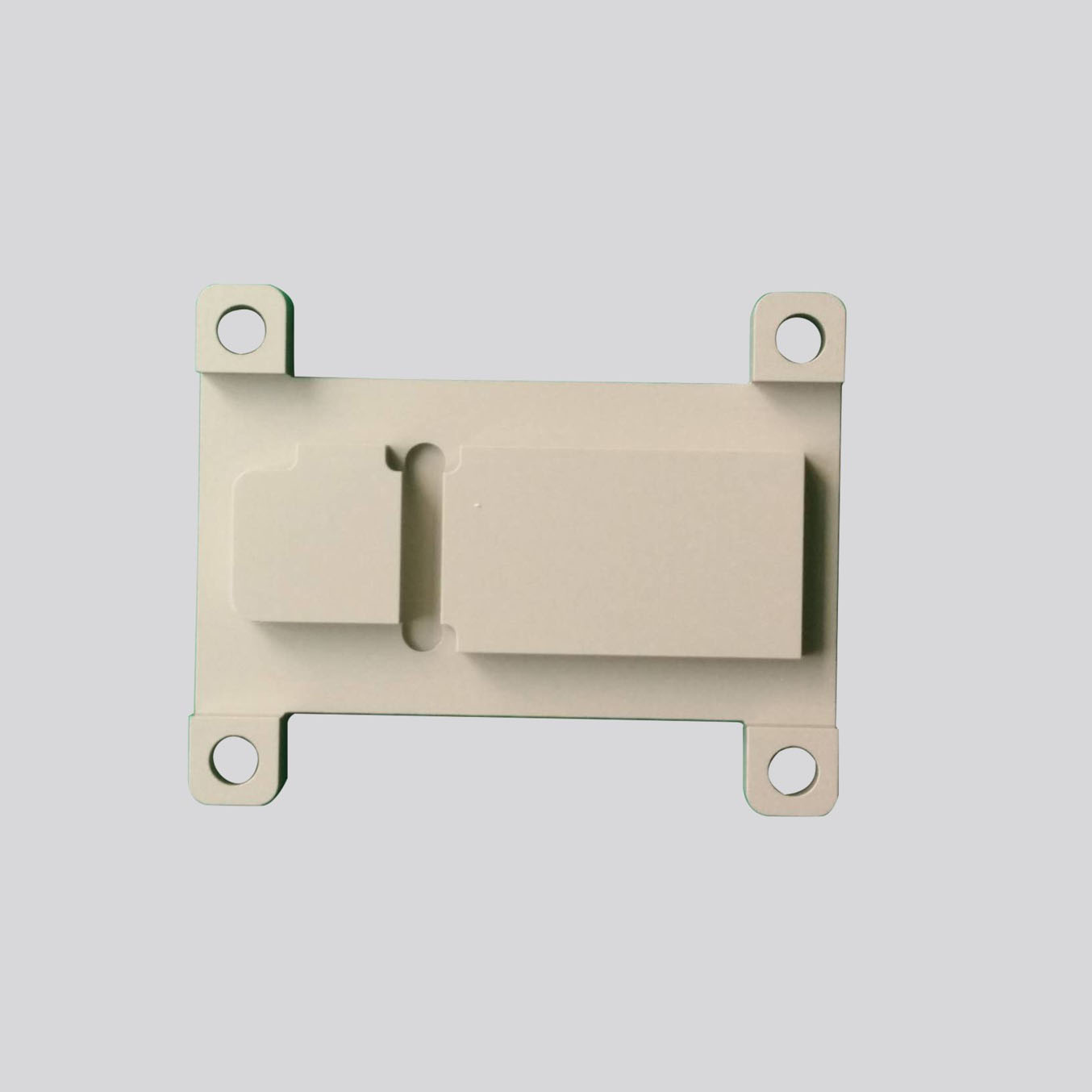

Molybdenum and copper’s properties include efficient thermal conductivity and suited coefficient of thermal expansion (CTE) with the CTE of electronic components. In addition, molybdenum copper has excellent hermeticity and machinability. All these properties help moly copper composites to be capable material of heat sinks, heat spreaders, and other baseplates applied in IGBT, LDMOS, and GaN/GaAs-based devices.

Well-matched CTEs are a critical concern when choosing the material of the heat sinks and heat spreaders in high frequency and high power electronic components.

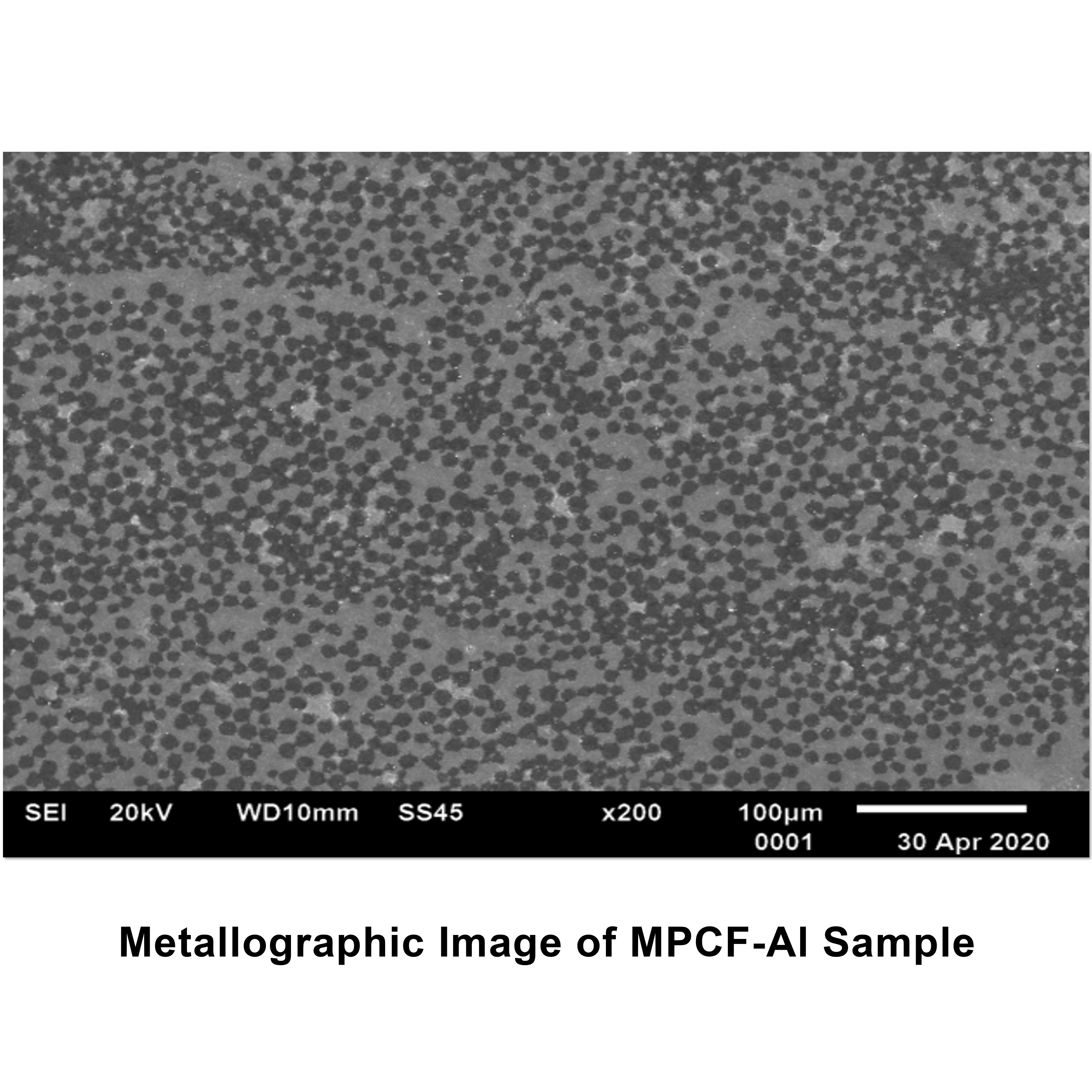

Molybdenum copper materials have a wide range of Mo and Cu ratios from Mo60Cu40 to Mo85Cu15. Each ratio defines a specific CTE ranging from 5.6x 10-6/K to 11.5×10-6 K. This range covers the CTEs range, 3×10-6/K to 10×10-6/K, of semiconductor and ceramic packaging materials. The common semiconductor materials include Si, GaN, and GaAs. The common ceramic packaging materials are Al2O3, BeO, AlN, and SiC. The CTE of molybdenum copper composites can pair with the CTE of these materials. The well-matched CTEs combination can achieve a reduction of thermal stresses. As a result, the reduction improves the operation reliability and the electronic components’ lifespan.

Molybdenum copper has an excellent thermal spreading effect. It is a vital property for heat sinks and heat spreaders in high-power and high-frequency electronics. Take an example of the MoCu composites containing 15% to 18% copper.Mo75Cu25 exhibits outstanding thermal conduction as high as 160 W·m-1 ·K-1. While copper tungsten composite materials with comparable copper fractions exhibit relatively high thermal and high electrical conductivity, molybdenum copper has a lower specific density and superior machinability. Both are necessary concerns for weight-sensitive and integrated micro-electronics.

Therefore, molybdenum copper is a well-suited material for heat sinks and heat spreaders by virtue of its superb heat dissipation, electrical transmission, weight sensitivity, and machinability.

| Model | Combination(weight %) | Density | TC | CTE | |

| With | Mo | g/cm3 | w/m.k | 10-6/K | |

| Mo90Cu10 | 10±1 | Balance | 10.0 | 150-160 | 5.6 |

| Mo85Cu15 | 15±1 | Balance | 9.93 | 160-180 | 6.8 |

| Mo80Cu20 | 20±1 | Balance | 9.90 | 170-190 | 7.7 |

| Mo70Cu30 | 30±1 | Balance | 9.80 | 180-200 | 8.1 |

| Mo60Cu40 | 40±1 | Balance | 9.66 | 210-250 | 10.3 |

| Mo50Cu50 | 50±1 | Balance | 9.54 | 230-270 | 11.5 |

| Airtightness ≤ 5 x10-9 Pa/m3.s The composition of Mo and Cu can be adjusted, MoxCuy, x+y=100. | |||||