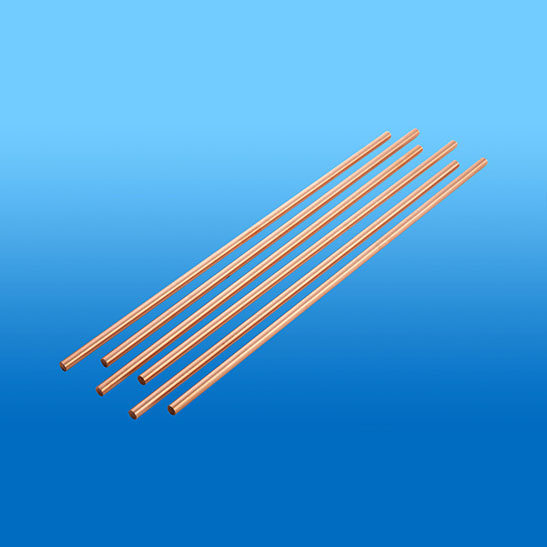

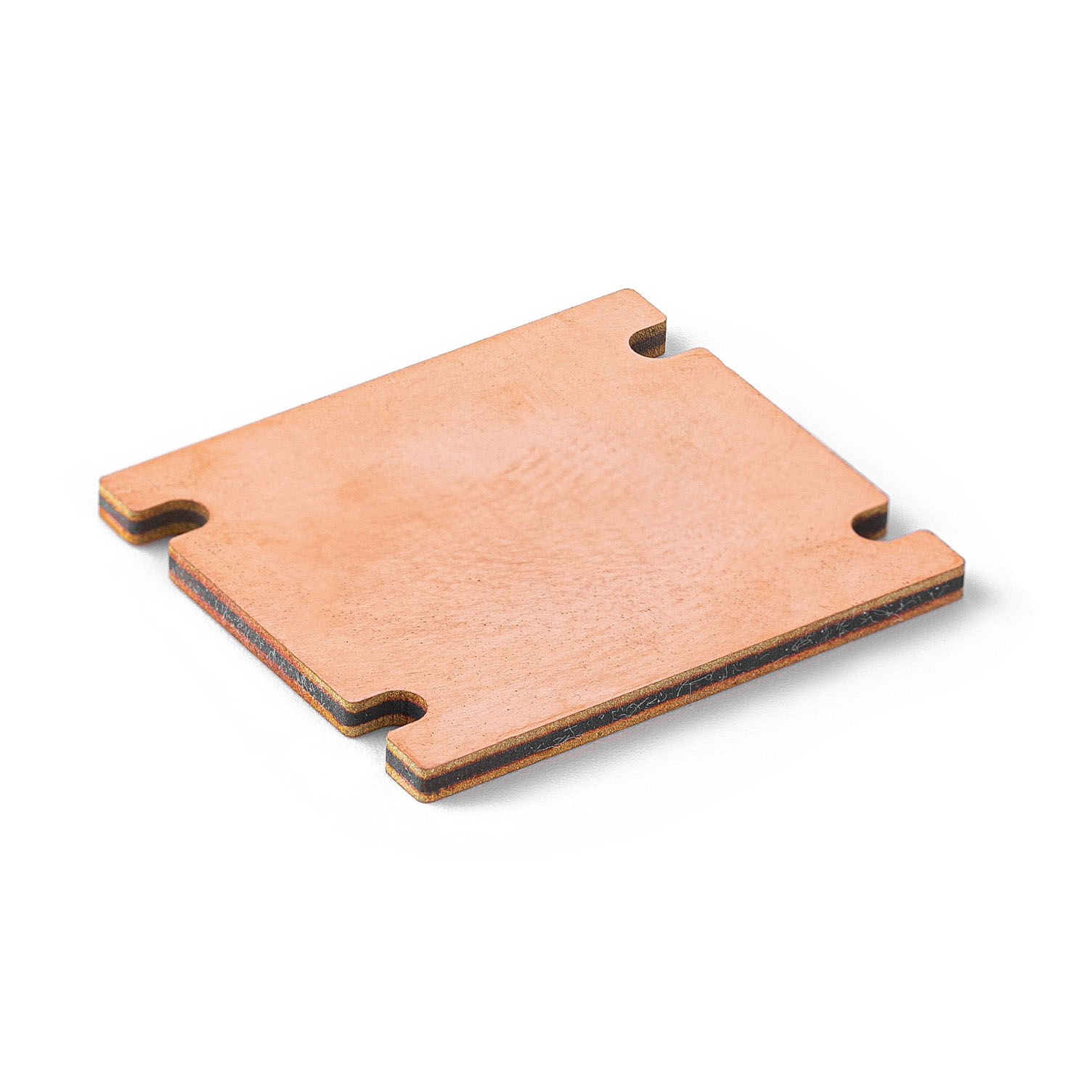

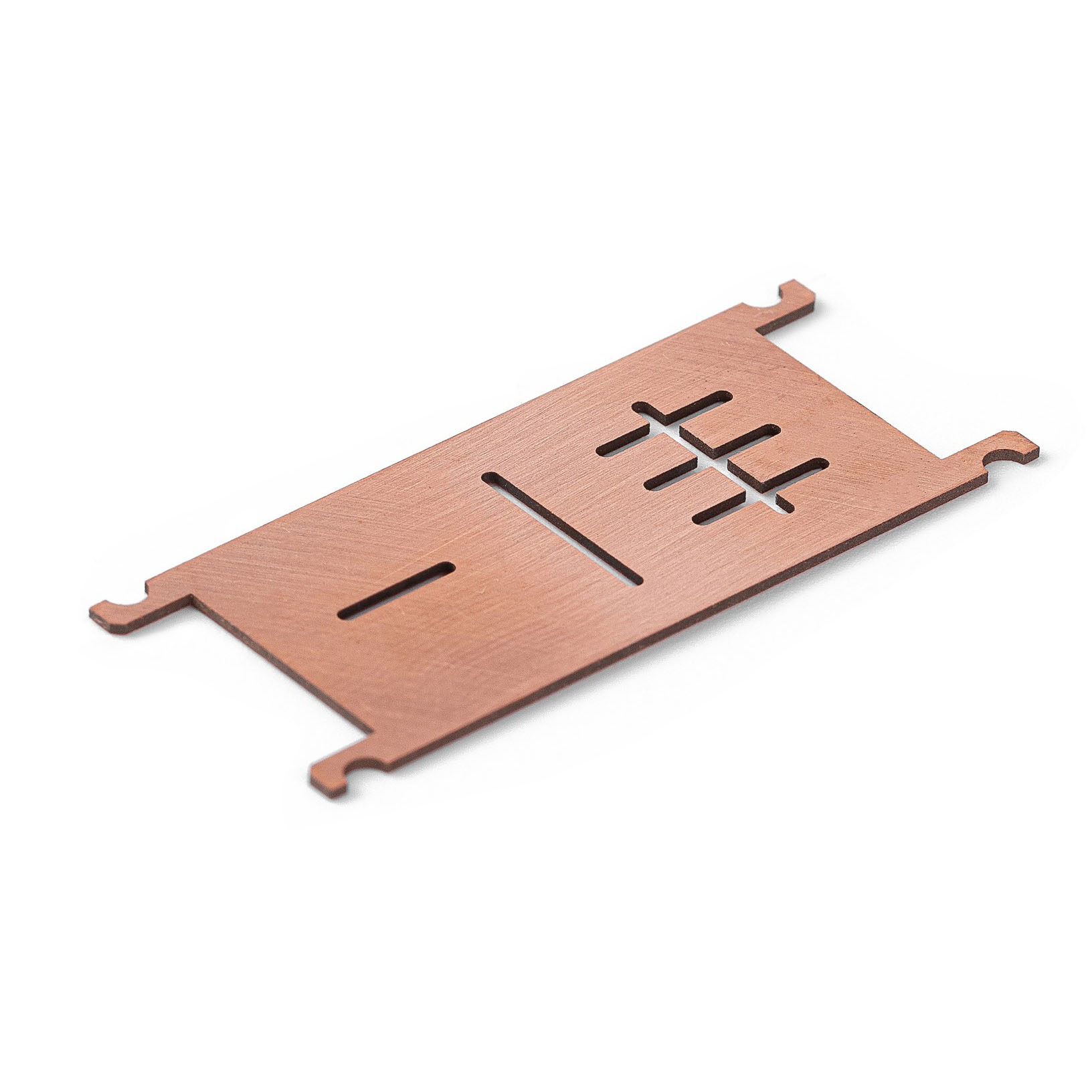

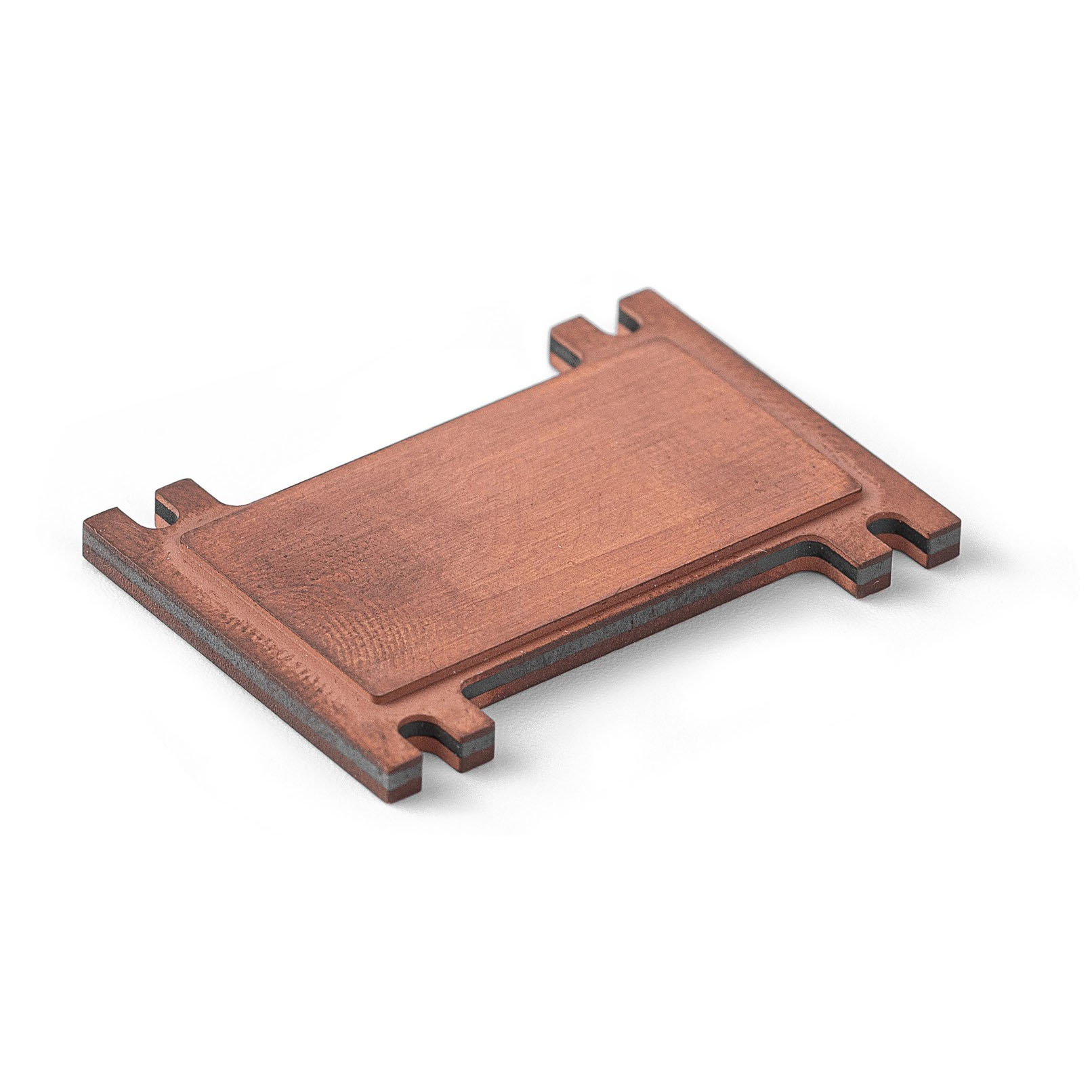

Cu/MoCu/Cu

Features:

- It has a higher thermal conductivity than copper/molybdenum/copper materials.

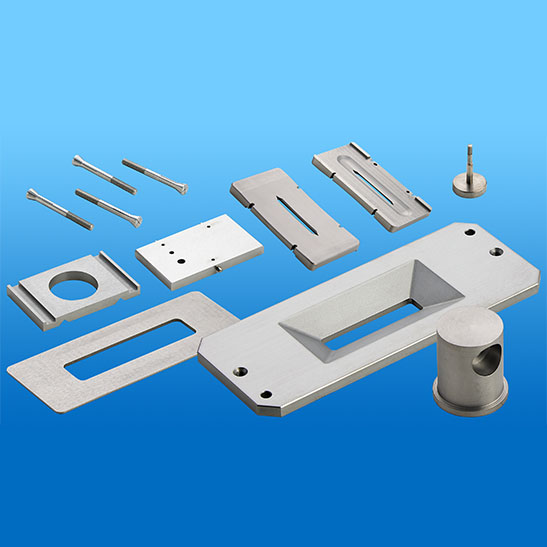

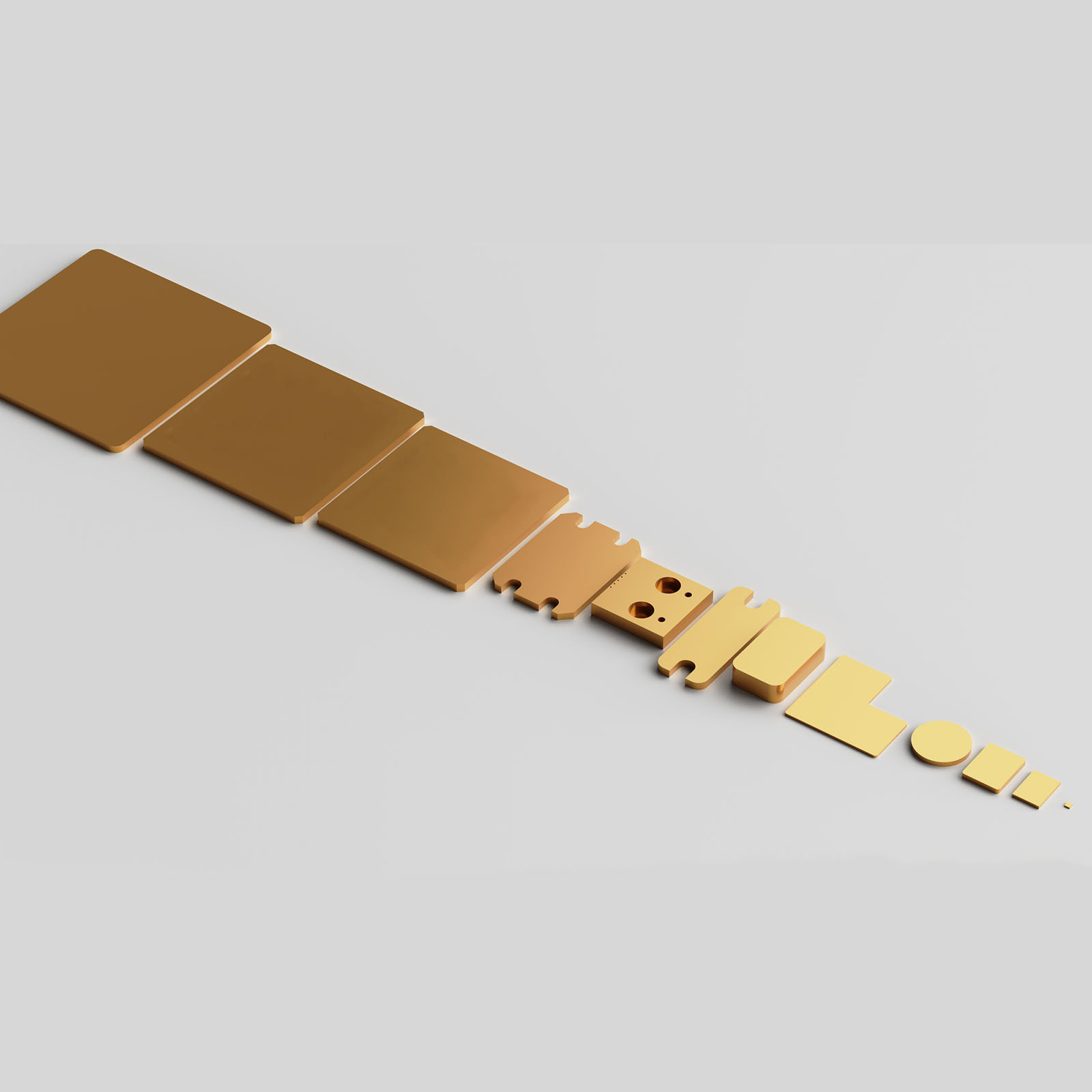

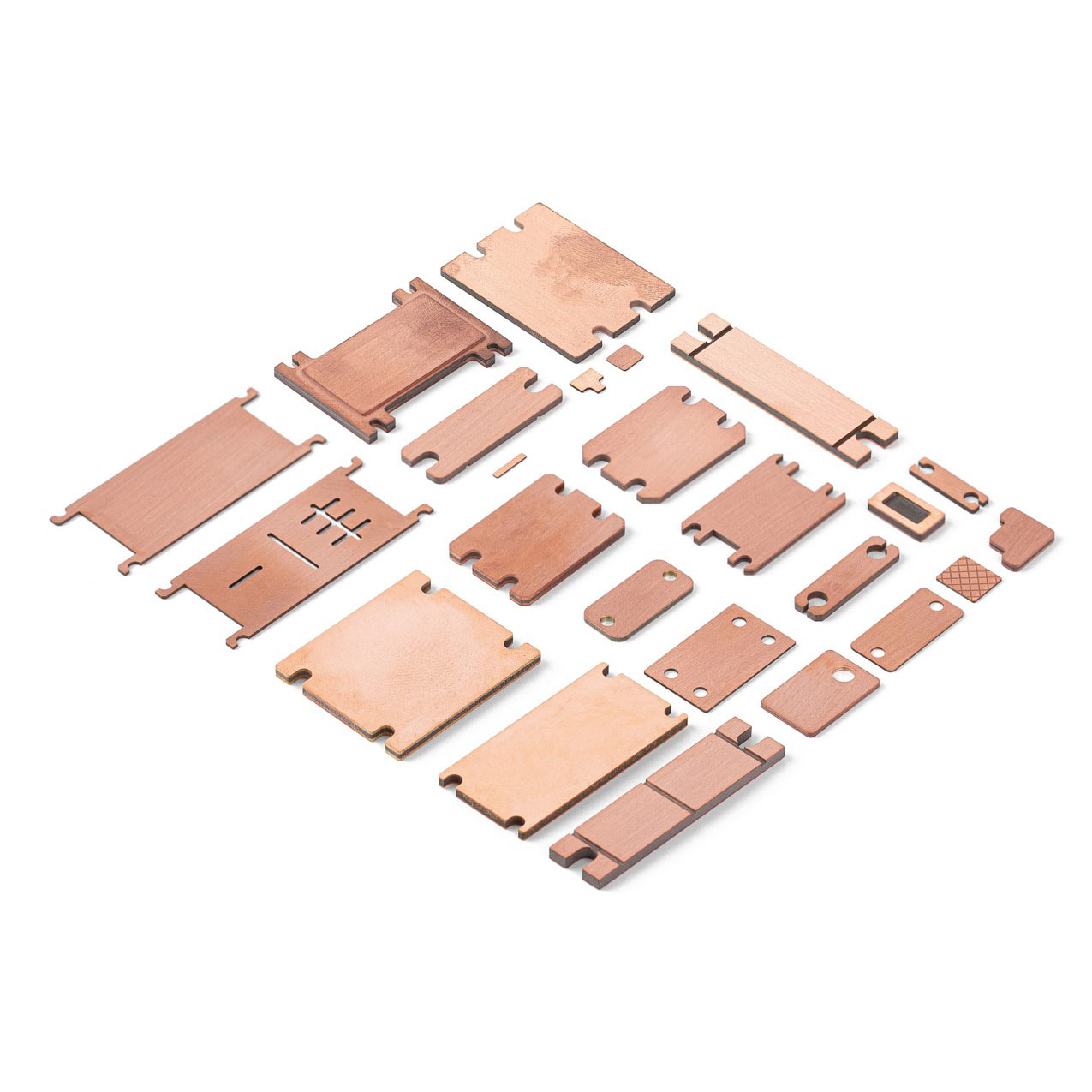

- It can be stamped into parts to reduce the cost.

- It has strong interfacial bonding, that can withstand repeated impacts at 850℃.

- It has a designable coefficient of thermal expansion, compatible with semiconductors and ceramics.

- It is non-magnetic.

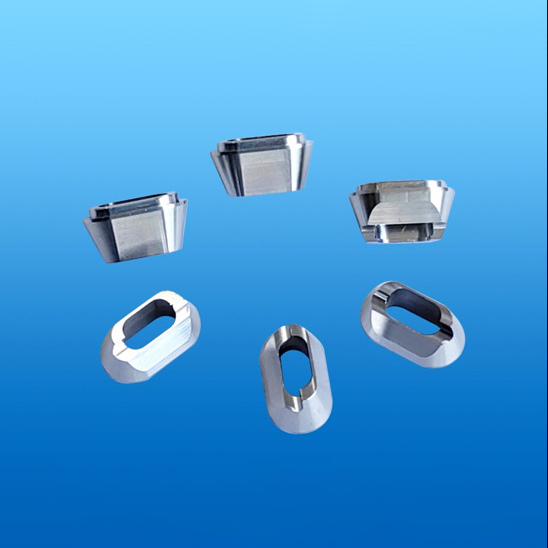

Applications:

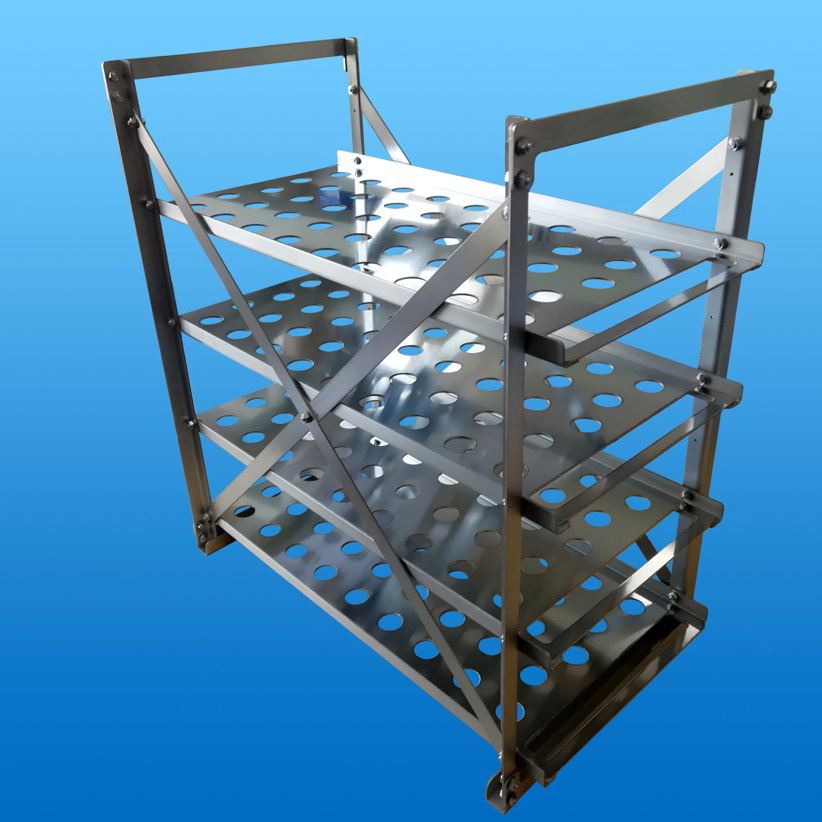

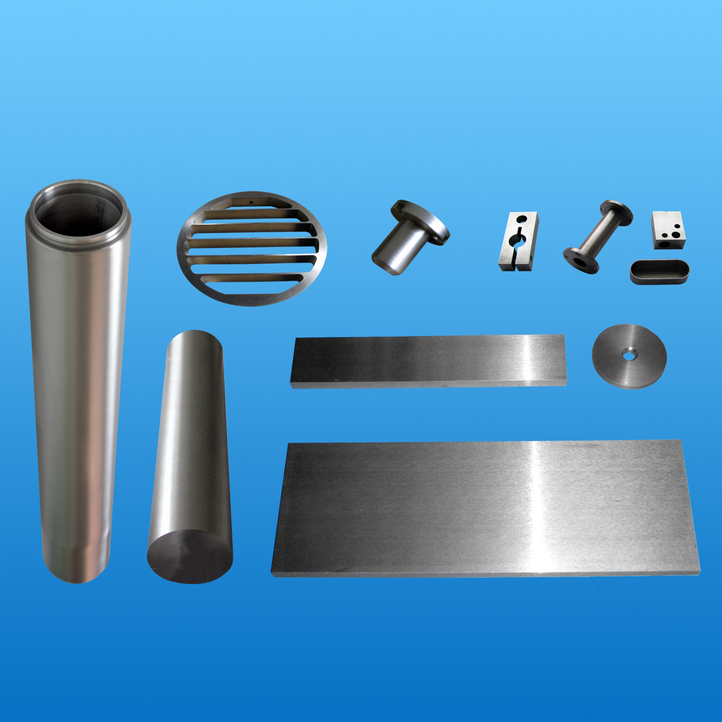

- Thermal mounting plates

- Chip carriers for microwave components

- Flanges and frames for RF and laser diode packages, LED packages,

- BGA packages and GaAs device mounts etc.