Pure Tungsten & Strengthened Tungsten

Tungsten Properties:

- High Density: 19.25 g/cm³ (nearly double that of lead, and comparable to uranium and gold)

- High Melting Point: 3422°C (The highest melting point of all known elements except carbon)

- Low Vapor Pressure

- High Tensile Strength

- Low Coefficient of Thermal Expansion

- Low Electrical Resistivity

- Good Machinability

- High Absorption Capacity

- High Elastic Modulus

Tungsten Applications:

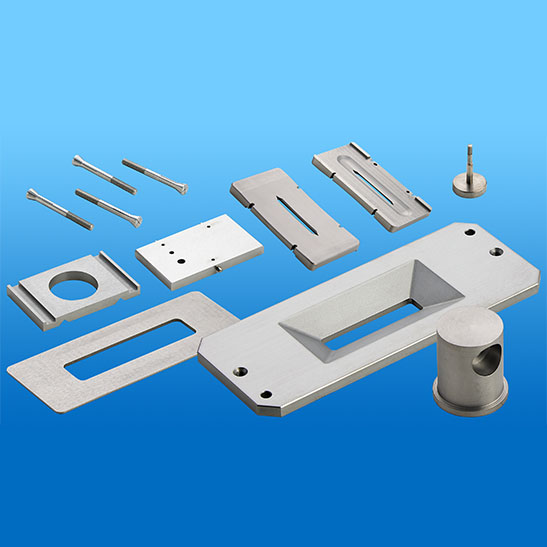

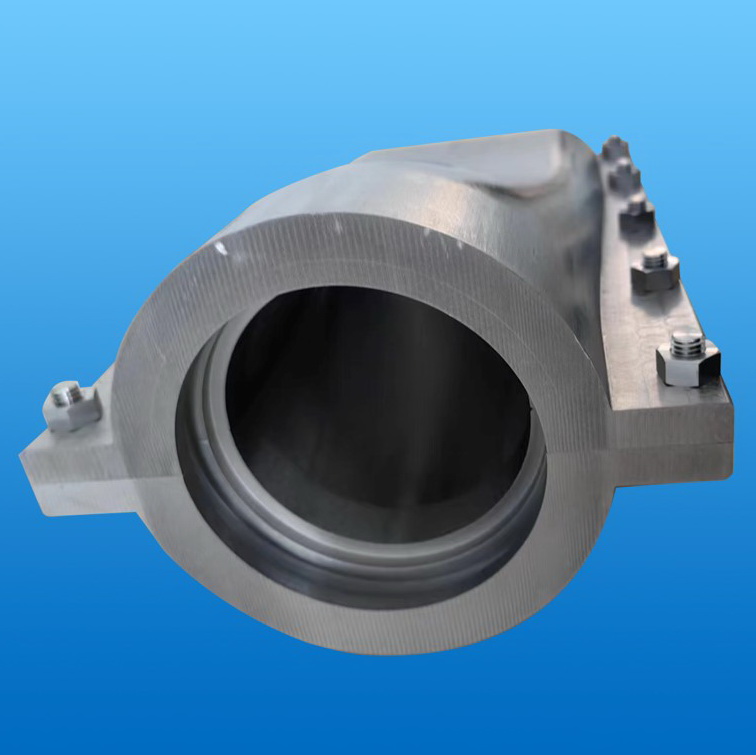

Despite its rarity, tungsten is among the most used materials in high-tech industries, including military; aerospace; nuclear energy; electronics; and chemical. Tungsten can be used to produce cutting tools; gas-turbine blades; thermal tubes; electronic contacts and radiation shields; and high temperature furnace parts, among many others. Such products usually contain a small percentage of other metals to amplify or augment its essential properties. These alloying metal and non-metal elements include molybdenum; titanium; tantalum; carbon; copper; nickel; and zirconium, to name a few.

In summary, tungsten’s myriad performance attributes are critical across an almost unimaginable range of industries and applications, from health care to quartz glass; coating and thermal processes to ion implantation.

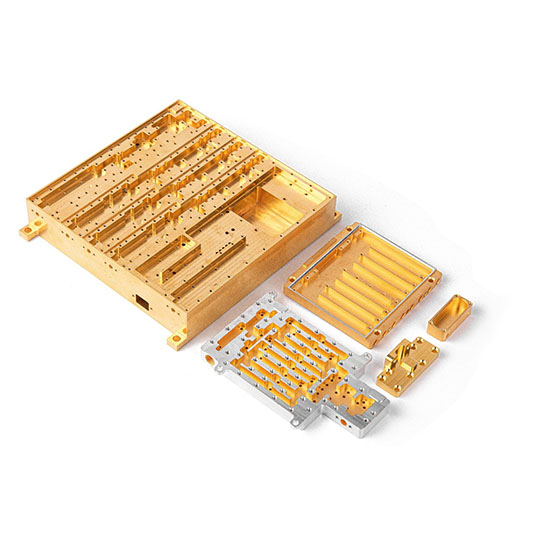

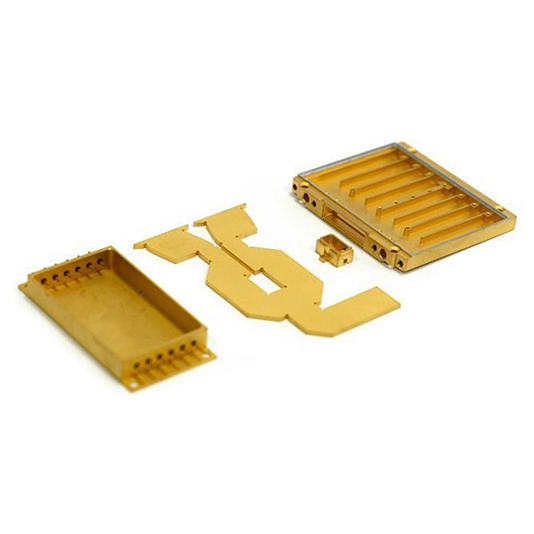

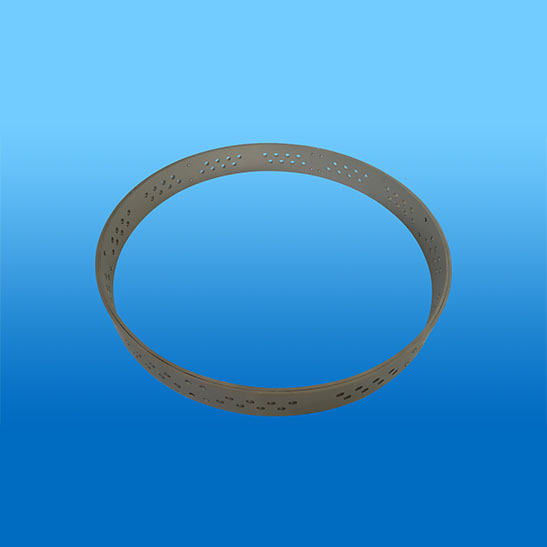

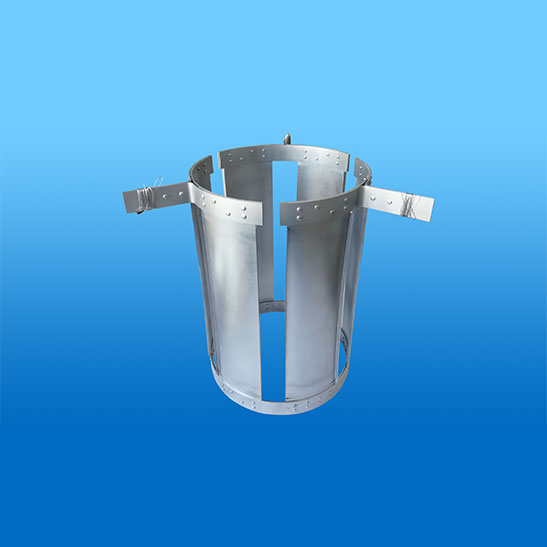

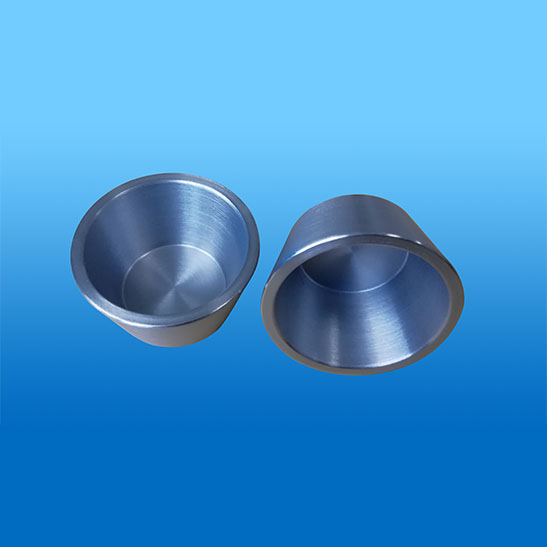

- Furnace Components

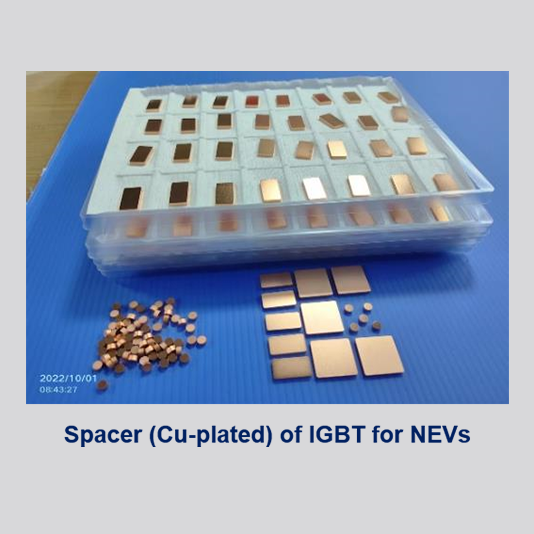

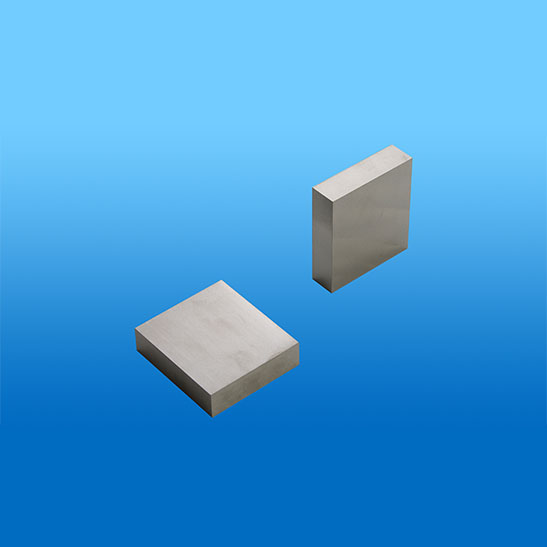

- Semiconductor Base Plates

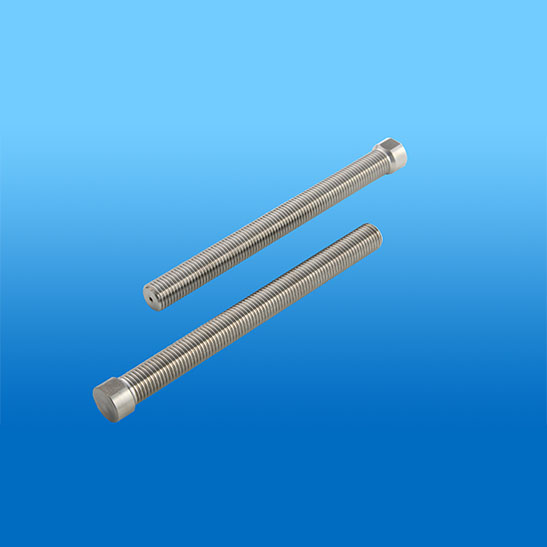

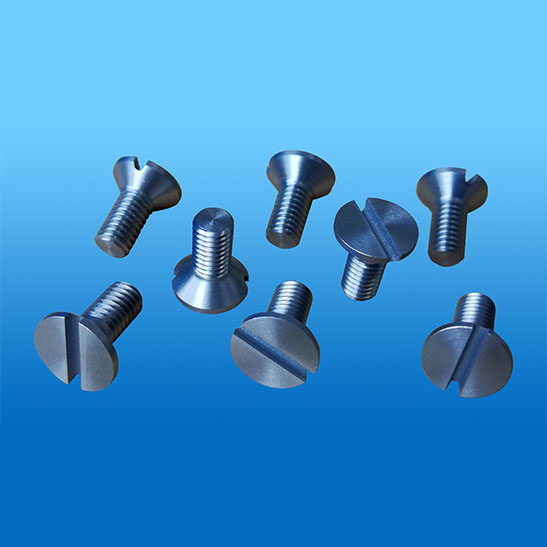

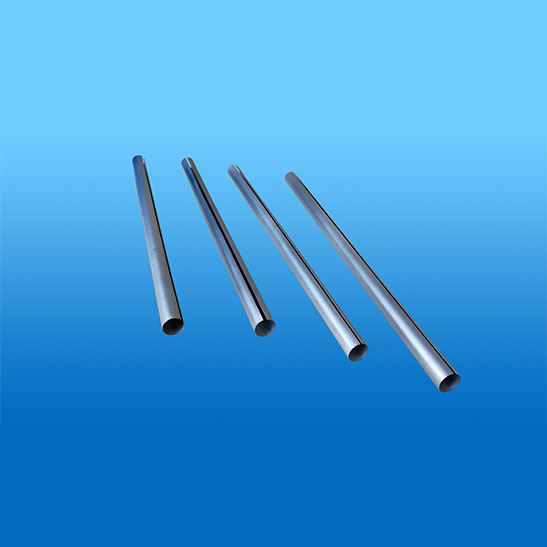

- Ion Implantation Cathodes And Anodes

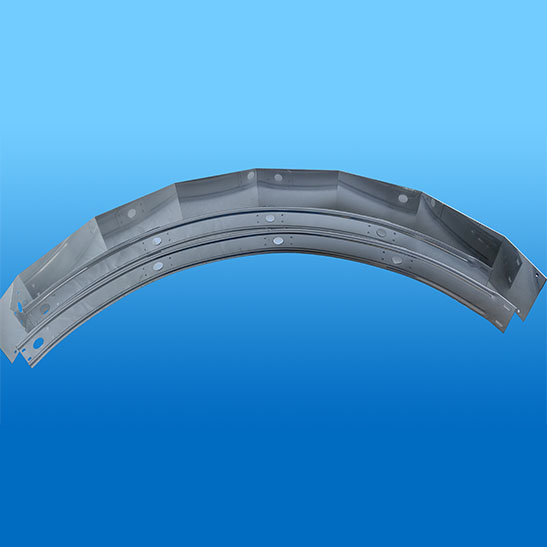

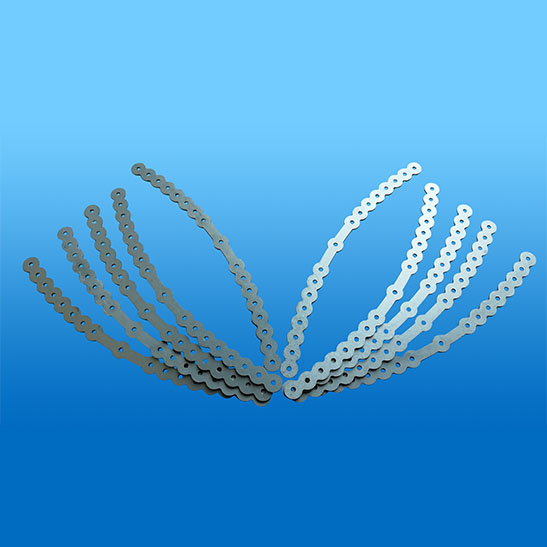

- Sintering And Annealing Boats And Charge Carriers

- Radiation Shielding, Sputtering Targets and Electrodes

- Components for Electron Tubes

Lanthanated tungstenis an oxidized lanthanum doped tungsten alloy, categorized as oxidized rare earth tungsten (W-REO). When dispersed lanthanum oxide is added, lanthanated tungsten displays enhanced heat resistance, thermal conductivity, creep resistance, and a high recrystallization temperature. These outstanding properties help lanthanated tungsten electrodes achieve exceptional performance in arc starting ability, arc erosion resistance, and arc stability and controllability.

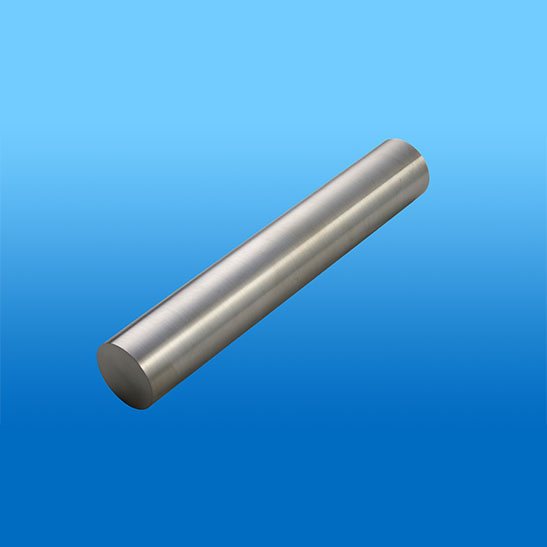

We have the capacity to manufacture W-La2O3, W-CeO2, W-Y2O3, and other oxidized rare earth tungsten rods. They are mainly used as electrodes and cathodes in many applications. We are also dedicated to researching and developing qualified oxide rare earth tungsten flat materials.

Rare earth oxide doped tungsten electrodes, such as W-La2O3 and W-CeO2, possess many superior welding characteristics. Rare earth oxide doped tungsten electrodes represent the best properties among electrodes for Gas Tungsten Arc Welding (GTAW), which is also known as Tungsten Inert Gas (TIG) welding and Plasma Arc Welding (PAW). The oxides added to tungsten increased the recrystallization temperature and, at the same time, promoted the emission level by lowering the electron work function of the tungsten electrode.

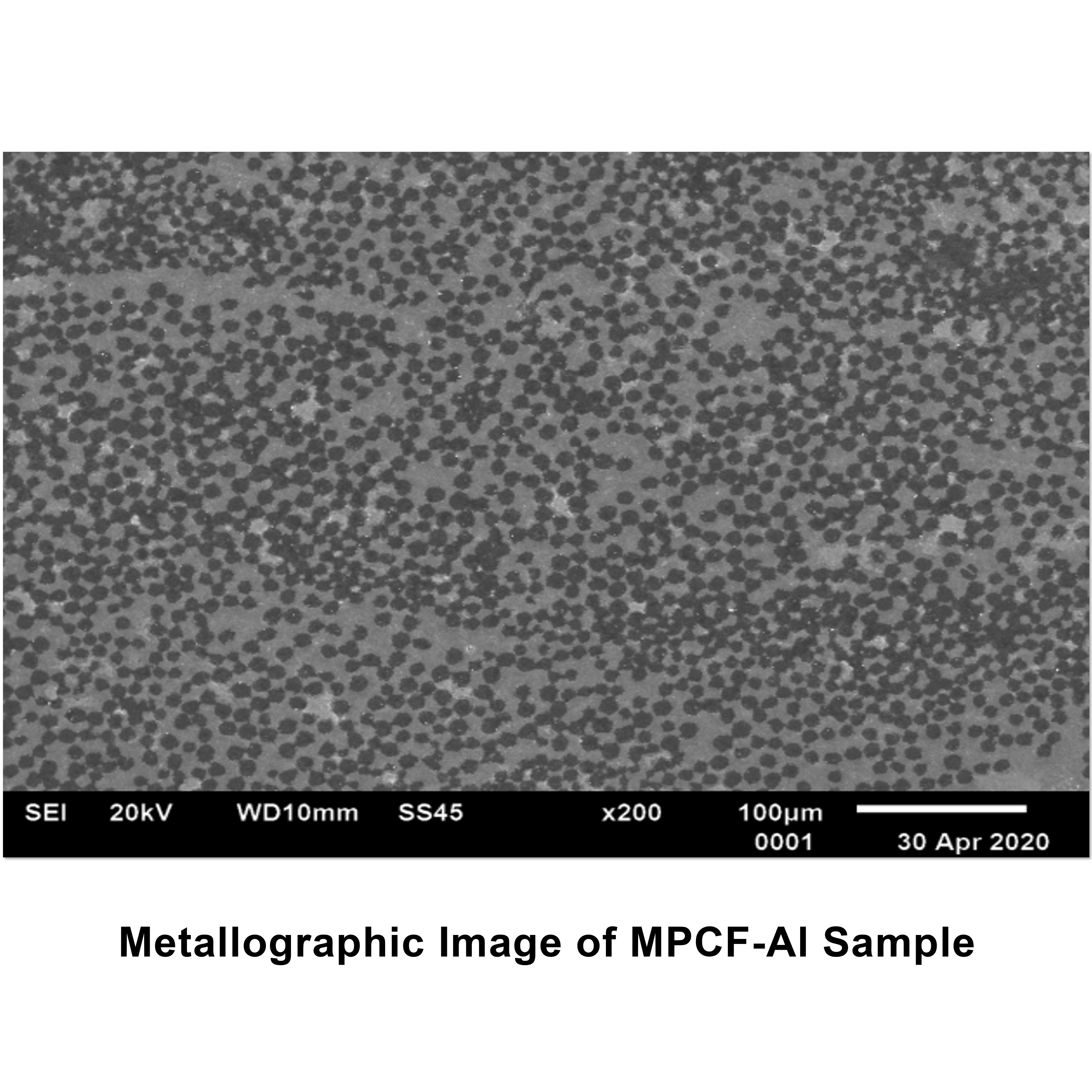

Potassium (K) -doped tungstencontains nano-bubbles on the order of ppm can hinder the motion of grain boundaries and dislocations, they lead to strengthening at a high temperature and suppression of recrystallization and can produce finer grains compared to pure W. This grain refining also leads to strengthening and toughening. Moreover, it is expected that neutron-irradiation-induced embrittlement can be suppressed in K-doped W compared to pure W because it contains a large number of grain boundaries that act as sinks for defects formed by the neutron irradiation.