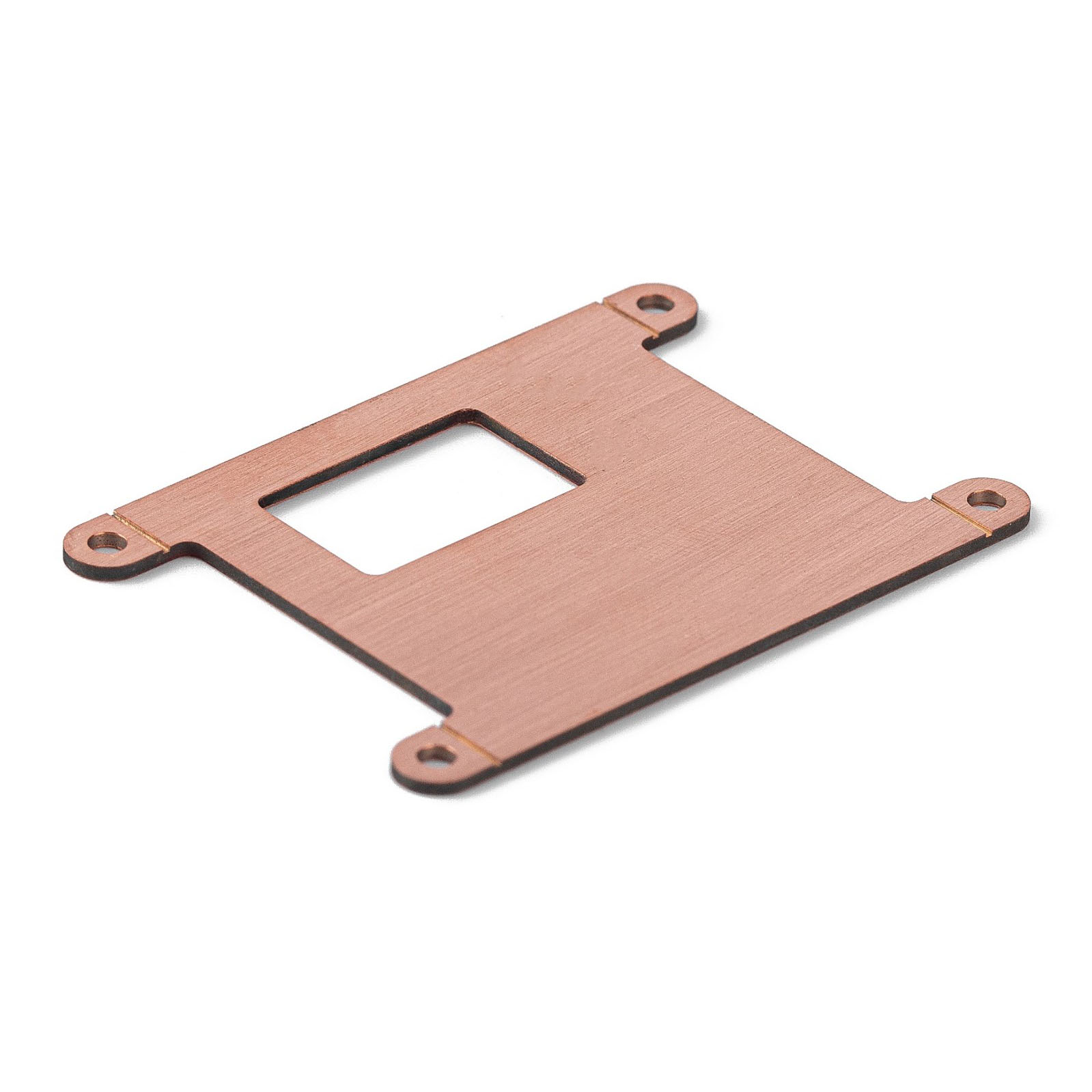

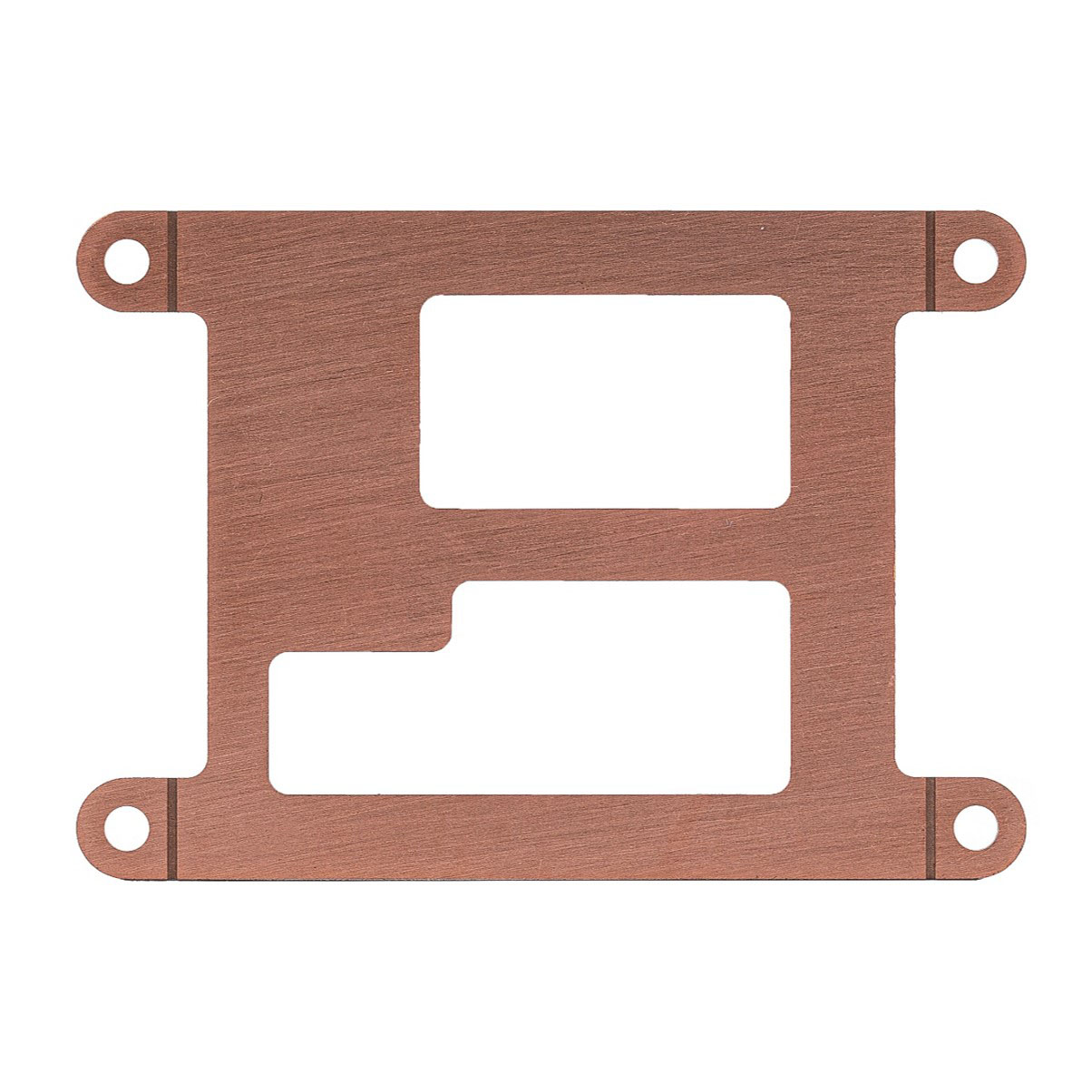

Cu/Mo/Cu

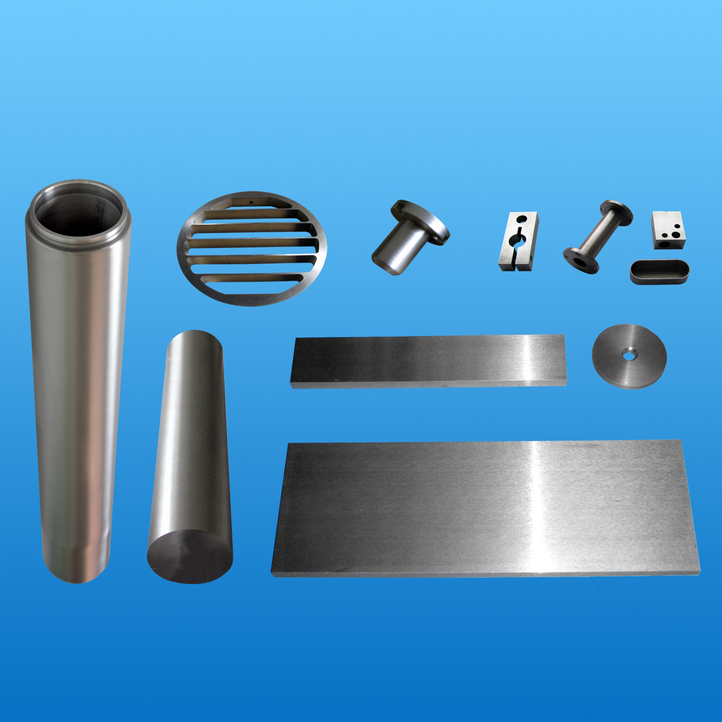

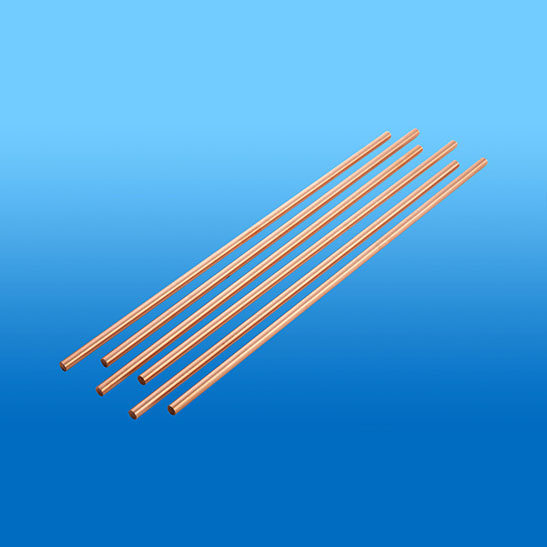

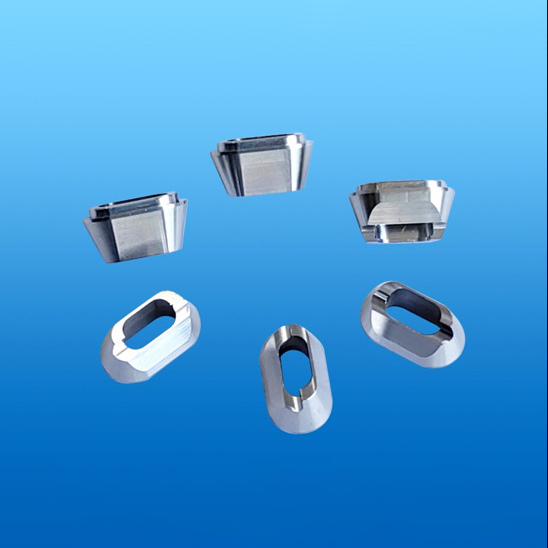

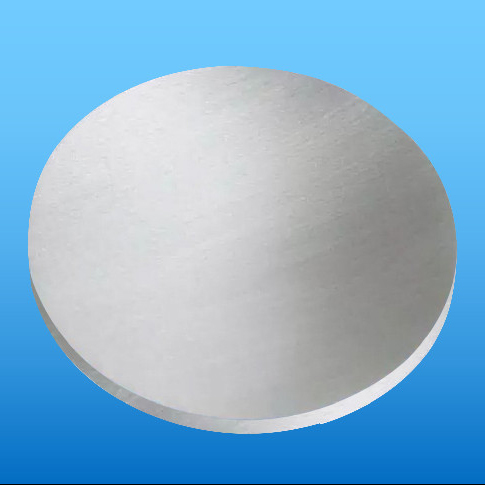

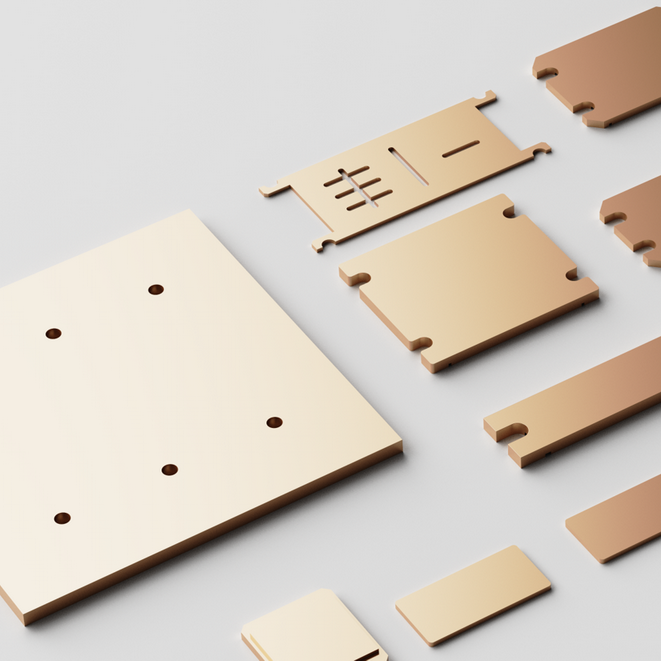

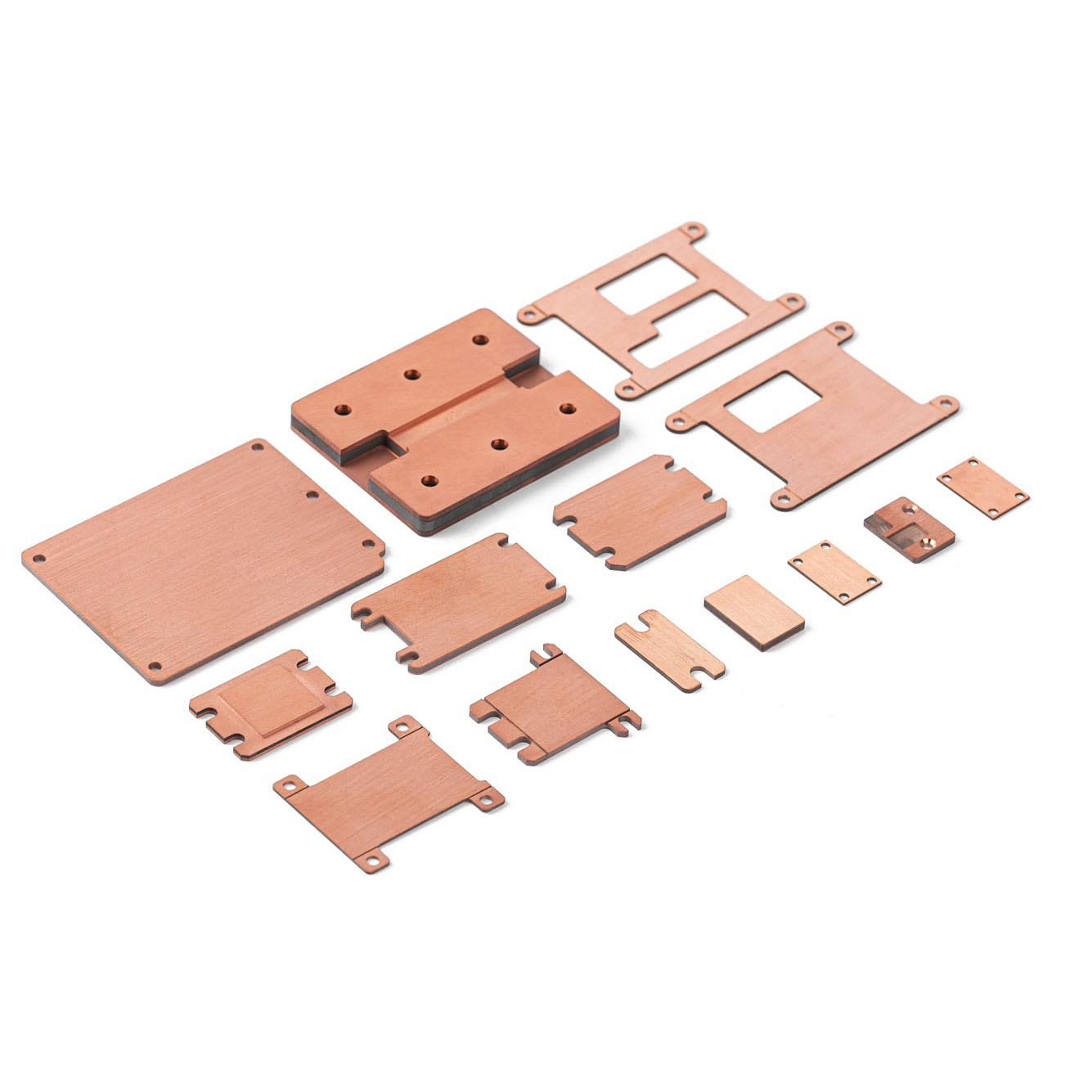

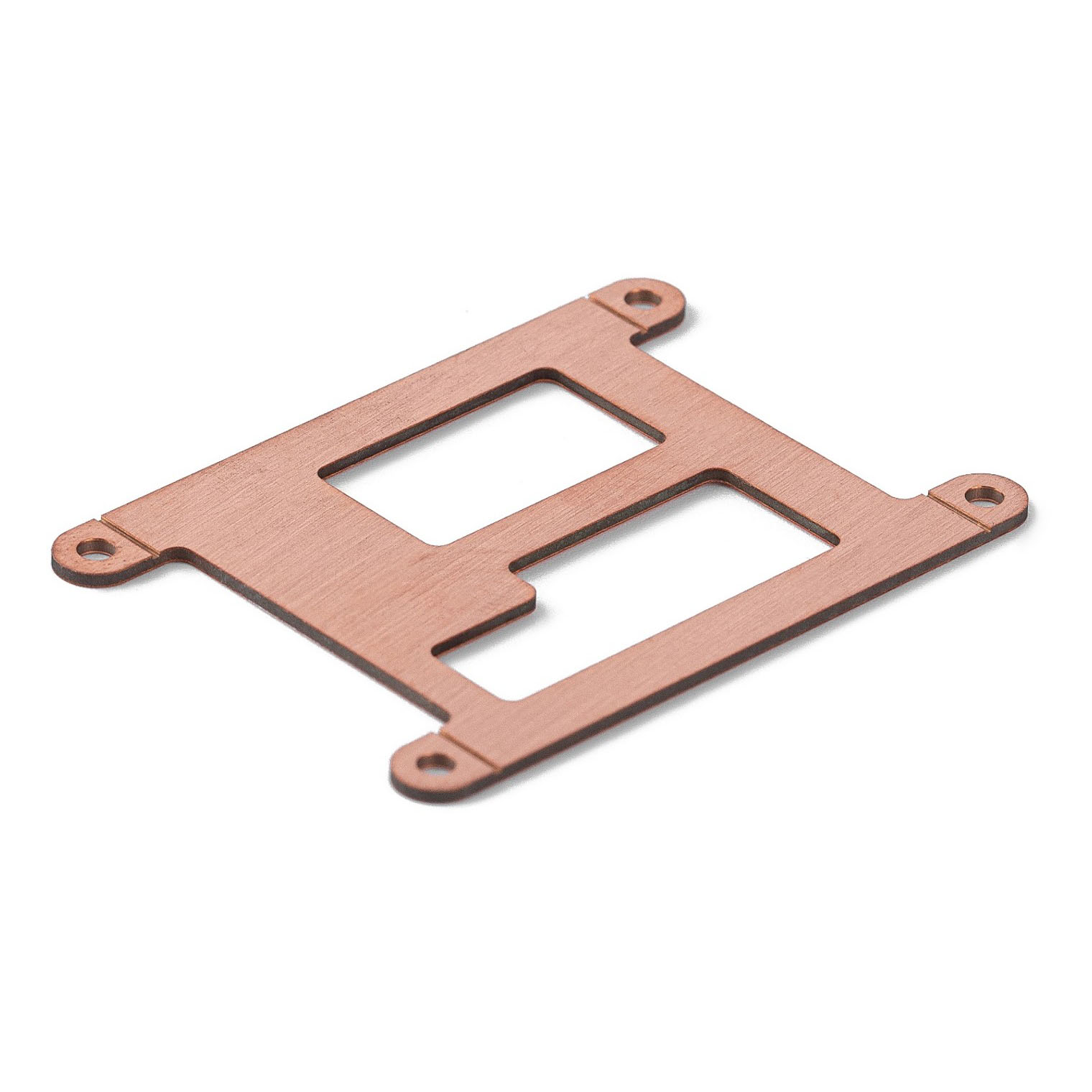

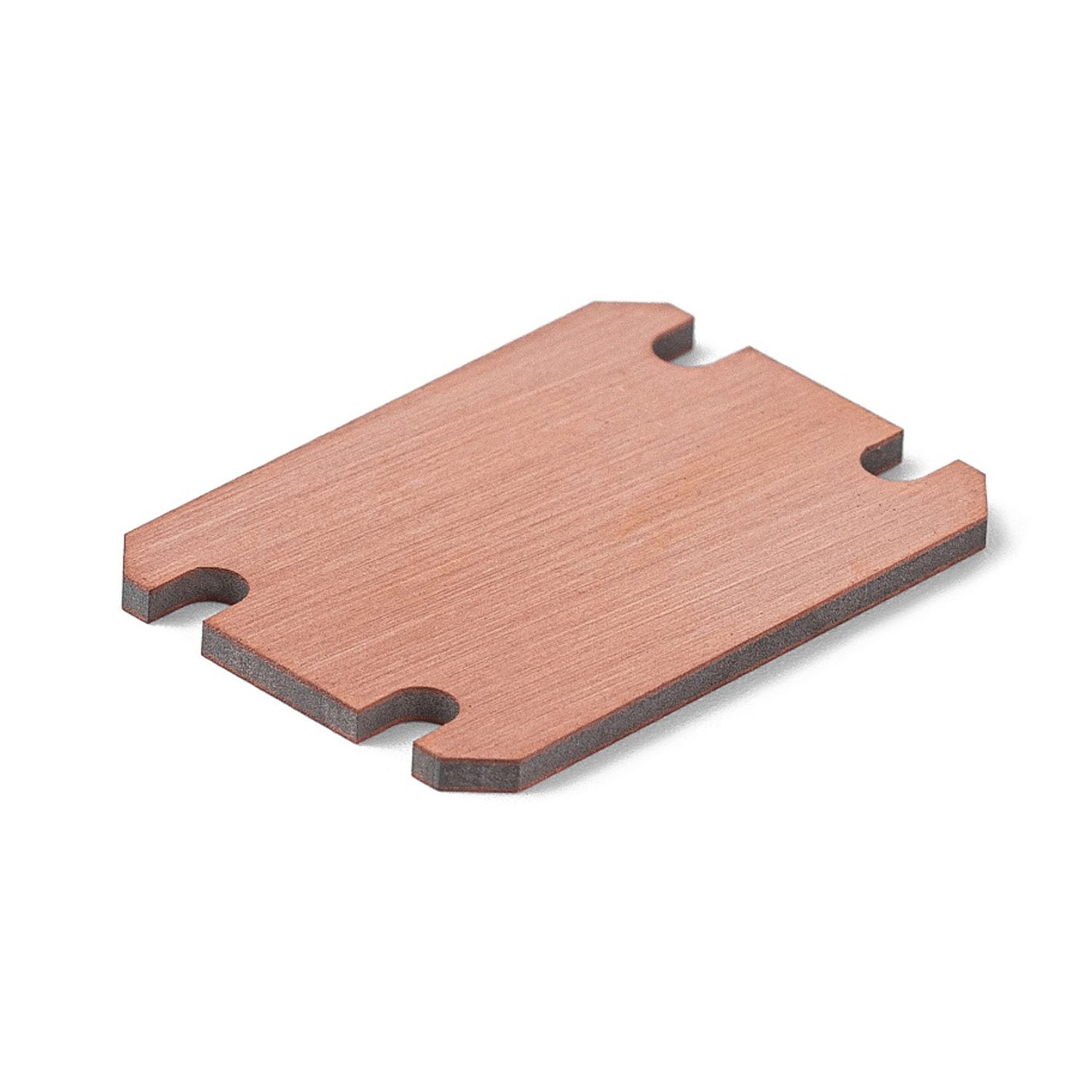

Copper Clad Molybdenum (CPC, CMC, and SCMC) are structures comprised of alternating layers of Mo/MoCu and Cu materials.

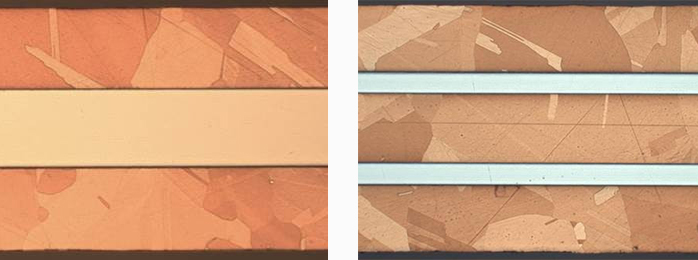

Multiple layers of Mo and Cu, or MoCu and Cu, in various combinations, are symmetrically roll-bonded to exacting thickness ratios. These firmly bonded layers must not vary in thickness by more than 10% from specifications. All interfaces of molybdenum copper laminates must be as clear and flat as possible to eliminate deleterious cracking or flaking. The copper outer layer has high thermal conductivity and efficient heat spreading qualities. The molybdenum layer inserted between copper layers maintains the overall coefficient of thermal expansion of the laminate in an appropriate range for the intended application. The superior, combined thermomechanical properties of molybdenum and copper have long been known by electrical power engineers who saw the potential of Mo and Cu laminates in many high frequency and high power applications.

| Material | Density | CTE | TC (W/M.K) | |

| g/cm3 | 10-6/K | In-Plan | Through-thickness | |

| Tue/Mon/Tuesday13:74:13 | 9.88 | 5.6 | 200 | 170 |

| Cu/Mo/Cu1:4:1 | 9.75 | 6.0 | 220 | 180 |

| Cu/Mo/Cu1:3:1 | 9.66 | 6.8 | 244 | 190 |

| Cu/Mo/Cu1:2:1 | 9.54 | 7.8 | 260 | 210 |

| Cu/Mo/Cu1:1:1 | 9.3 | 8.8 | 305 | 250 |

| H-S-CMC131213 | ||||

| S-CMC 5:1:5:1:5 | 9.2 | 200℃ 12.8 /20-800℃ 6.1 | 350 | 295 |

| S-CMC313-5 | 9.66 | |||

| S-CMC612-5 | 9.54 | |||