Tungsten muaj qhov siab tshaj plaws melting point ntawm tag nrho cov hlau nrog rau qhov zoo kawg nkaus modulus ntawm elasticity. Ua tsaug rau nws cov khoom siv thermal zoo, tungsten tuaj yeem yooj yim tiv taus txawm tias qhov kub siab tshaj plaws. Tungsten tseem sawv tawm rau nws qhov chaw ntoj ntom heev thiab yog li ntawd siv nyob rau hauv ntau yam kev lag luam thiab aerospace kev lag luam, thiab hauv cov khoom siv hluav taws xob.

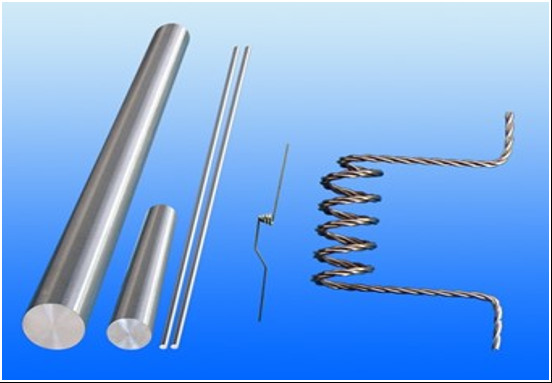

Tungsten tus thawj daim ntawv thov rau ntau tshaj 100 xyoo tau ua lub filament nyob rau hauv incandescent teeb. Doped nrog me me ntawm cov poov tshuaj-aluminium silicate, tungsten hmoov yog sintered ntawm qhov kub thiab txias los tsim cov hlau filament uas yog nyob rau hauv nruab nrab ntawm lub teeb qhov muag teev uas teeb ntau lab lub tsev nyob ib ncig ntawm lub ntiaj teb no.

Vim tias tungsten muaj peev xwm khaws nws cov duab ntawm qhov kub thiab txias, tungsten filaments tam sim no kuj tau siv rau hauv ntau hom kev siv hauv tsev, nrog rau cov teeb, teeb pom kev zoo, cov khoom cua sov hauv cov cub hluav taws xob, microwaves, thiab x-ray raj.

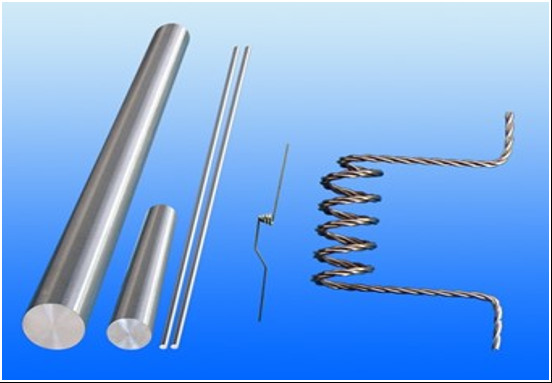

Cov hlau ua siab ntev rau cov cua sov kuj ua rau nws zoo tagnrho rau cov thermocouples thiab hluav taws xob tiv tauj hauv hluav taws xob arc rauv thiab cov khoom siv vuam. Cov ntawv thov uas xav tau qhov hnyav, lossis qhov hnyav, xws li cov khoom hnyav, cov khoom siv nuv ntses, thiab darts feem ntau siv tungsten vim nws qhov ntom.

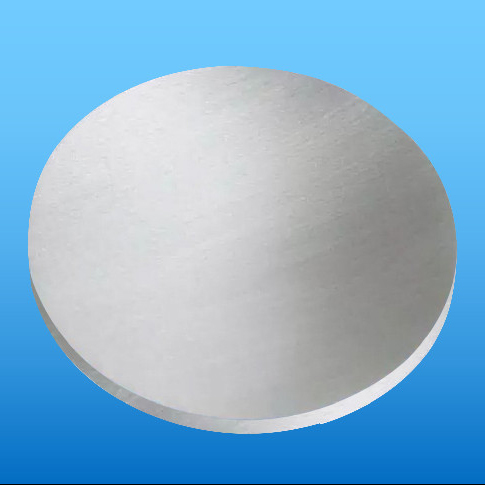

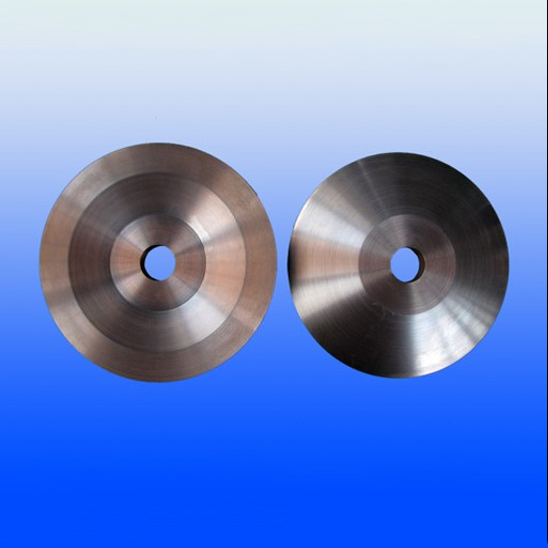

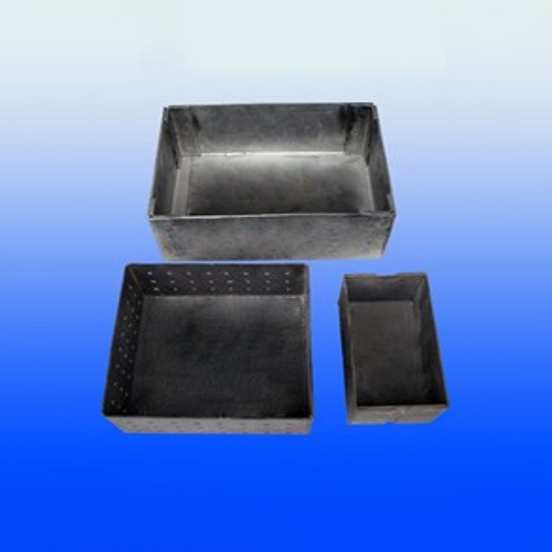

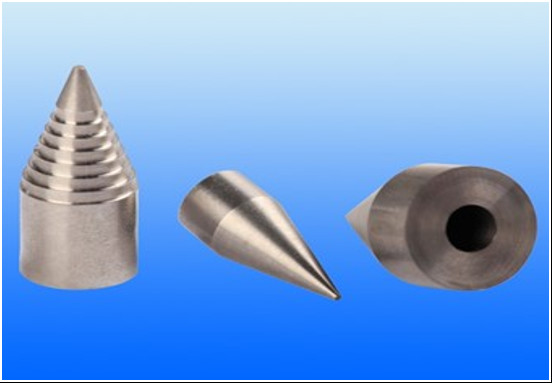

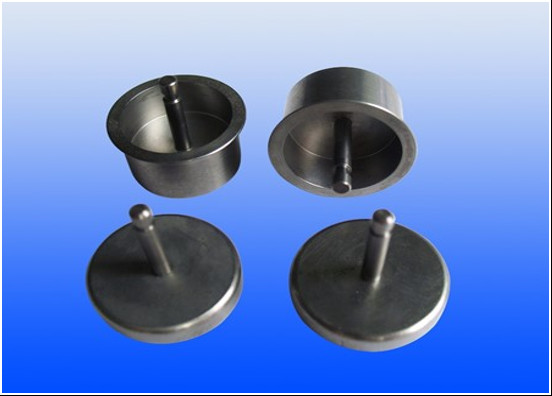

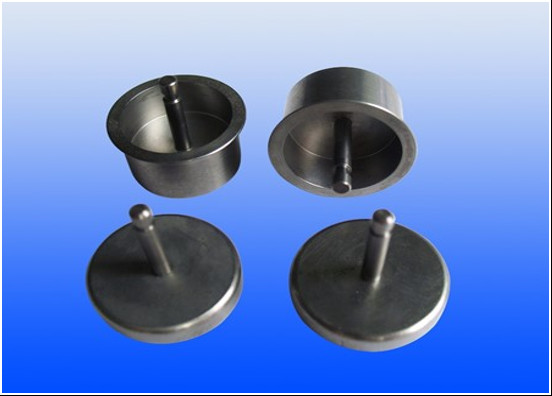

Nrog ib tug purity ntawm> 99.98%, nws yog dav siv nyob rau hauv semiconductor ion implantation Cheebtsam, cua sov ntsiab, sputtering lub hom phiaj, electrodes, high-temperature structural qhov chaw, siv lead ua crucibles, counterweights, hluav taws xob shielding, lub hwj chim ntaus ntawv kub dissipation thiab lwm yam sij hawm.

Peb tsim peb cov khoom tungsten los ntawm cov hmoov hlau rau cov khoom tiav. Peb tsuas yog siv cov ntshiab tungsten oxide ua cov khoom siv. Peb muab siab purity tungsten khoom nrog ib tug purity mus txog 8N.

oxidized tsawg ntiaj teb tungsten (W-REO)

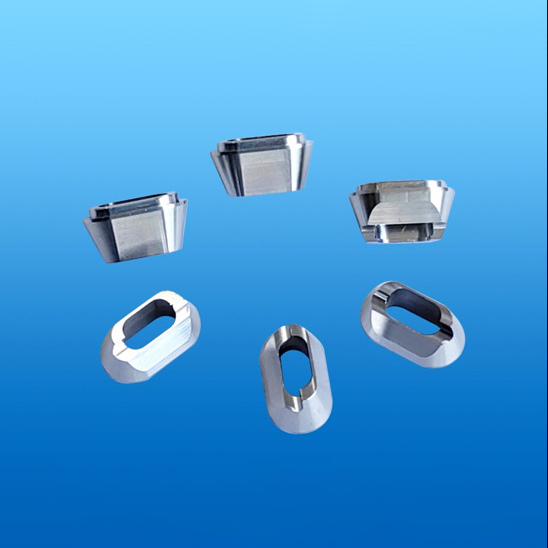

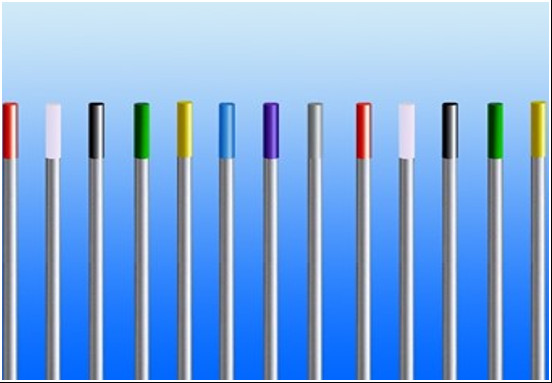

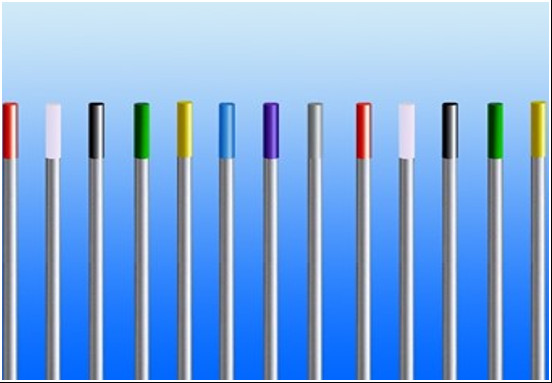

Oxidized tsis tshua muaj ntiaj teb tungsten (WLa, WCe, WTh, WY thiab lwm yam tsis tshua muaj lub ntiaj teb alloys) muaj lub zog ntau dua thiab kev tso tawm tshwj xeeb tshaj li cov tungsten ntshiab, thiab tau siv dav hauv ntau yam electrodes: TIG vuam, ntshav vuam, ntshav plasma vuam, plasma txau txheej, plasma smelting thiab gas paug lub teeb qhov chaw; nws kuj yog siv nyob rau hauv high-temperature structural qhov chaw.

Lanthanated tungsten yog oxidized lanthanum doped tungsten alloy. Thaum dispersed lanthanum oxide ntxiv, lanthanated tungsten qhia txog kev tiv thaiv tshav kub, thermal conductivity, creep resistance, thiab siab recrystallization kub. Cov cuab yeej zoo no pab lanthanated tungsten electrodes ua tiav qhov kev ua tau zoo tshwj xeeb hauv arc pib muaj peev xwm, arc yaig tsis kam, thiab arc stability thiab controllability.

Peb muaj peev xwm tsim W-La, W-Ce, WY, W-Th thiab lwm yam oxidized tsawg lub ntiaj teb tungsten. Lawv tsuas yog siv los ua electrodes thiab cathodes hauv ntau daim ntawv thov. Cov oxides ntxiv rau tungsten nce qhov kub ntawm recrystallization thiab, nyob rau tib lub sij hawm, txhawb cov emission theem los ntawm kev txo cov electron ua hauj lwm muaj nuj nqi ntawm tungsten electrode.

Potassium-doped Tungsten (Tungsten-potassium lossis WK)

Potassium (K) -doped W muaj nano- npuas ntawm qhov kev txiav txim ntawm ppm tuaj yeem cuam tshuam txoj kev txav ntawm cov ciam teb thiab kev tsis sib haum xeeb, lawv ua rau muaj zog ntawm qhov kub thiab txias ntawm recrystallization thiab tuaj yeem tsim cov nplej zoo dua piv rau cov ntshiab W. Cov nplej no. refining kuj ua rau kom muaj zog thiab toughening. Ntxiv mus, nws yuav tsum tau hais tias neutron-irradiation-induced embrittlement yuav raug suppressed nyob rau hauv K-doped W piv rau ntshiab W vim hais tias nws muaj ib tug loj tus naj npawb ntawm grain ciam teb uas ua raws li dab dej rau qhov tsis xws luag tsim los ntawm neutron irradiation.

Tungsten (W) yog suav tias yog ib qho ntawm cov neeg sib tw zoo tshaj plaws ntawm plasma-facing cov ntaub ntawv (PFMs) vim nws cov khoom tshwj xeeb, xws li hydrogen isotope tuav, tsis tshua muaj sputtering yield thiab siab melting point. Txawm li cas los xij, qhov tsis zoo, xws li qhov kub siab hloov mus rau qhov kub thiab txias (DBTT), brittleness ntawm qis kub thiab brittleness vim neutron irradiation yog obstacles rau engineering daim ntaub ntawv ntawm tungsten. Cov qauv tsim ntawm W-raws li alloys nrog ductile dopants yog ib txoj hauv kev zoo los txo cov kev tsis zoo no. Potassium doping twb tau ua pov thawj nws cov kev ua tau zoo hauv kev tiv thaiv cov txheej txheem recrystallization thiab tswj cov qoob loo loj hlob mus txog 1900 ° C hauv tungsten nyias cov xov hlau, thiab yog li qhia tau hais tias muaj zog tshwj xeeb ntawm qhov kub siab. Potassium-doped (K-doped) tungsten bulk khoom dhau los ua tus neeg sib tw txaus nyiam rau cov khoom siv plasma thiab. Nws tau raug tshaj tawm tias K-doped tungsten fabricated nrog sparking plasma sintering (SPS) qhia tau hais tias zoo thermal conductivity, nrog rau cov neeg kho tshuab muaj zog ntawm qhov kub ntawm RT mus rau 50 ° C.

Tsev

Tsev